Hey Jimmy.....Sorry, I'm not familiar with "Metal Rescue" from personal experience. I'll look into it though and let you (and the forum) know of opinions formed.

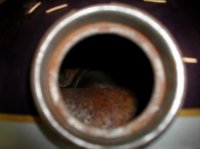

At present, I'm doing some comparative testings of chemical de-rusting systems and have been favorably impressed with "Evaporust" (nice to work with btw) rust removal and for different reasons "Rust Blast" from KBS Coatings which is step number 2 of their 3 part (clean, de-rust, seal) kit-system.....Their names "Aqua Klean"..."Rust Blast"..."Gold Seal". At first look...I like it a lot because it (Rust Blast) not only de-rusts but; etchs & leaves a zinc phosphate primer residue which both promotes adhesion of the subsequent sealer and coats the derusted metal surface to prevent flash oxidation (rusting) after de-rusting....(kind of a problem often encountered in a variety of process systems)

I'm still waiting for things to warm up a little....kind of like painting these systems like warmer (plus 70 degree temps.) and lower humidity, as several are one component moisture curing polymers.

In all these systems the cleaning, etching, priming, drying and surface prep & conditions are as important (if not more so) as the materials used not unlike painting or electroplating eg.

More later.... "Later"

"Metal Rescue" is a new de-rusting chemical material.....

~~~~~~~~~~~~~~~~~~~

ARMOR launches Metal Rescue

ARMOR Protective Packaging announces the launch of Metal Rescue. This rust remover is clean, safe and easy to use. It utilizes a unique and selective chelating agent to remove rust (iron oxide) without posing any health, safety or environmental concerns. For more information, visit the

www.metalrescue.com or email

info@armorvci.com

www.metalrescue.com

www.armorvci.com/portal/Uploads/WhatsNew/Metal Rescue Release April 2008.pdf

~~~~~~~~~~~~~~~~~~~

This "selective chelating agent" approach to reduction of iron oxide sounds very much like the

technology employed in the product "Evaporust". Also appears to be quite similar from viewing the videos. The issue of protecting the treated surface from flash re-rusting would remain as would the question of further etching/priming for subsequent sealing/coating/tank lining. Blue