Good post, wolds. What valve lash did you have while getting your data?

If you really want to get into it, determining valve lash is done by finding the sweet spot in the cam's entrance ramp. You'd need to set lash to zero, or just slightly tight so you can track the precise cam lift profile during the first 30°-45° or so.

You'll need to get the lift values for each degree of rotation.

Next, you'll need to produce the 1st order derivative values.

This will simply be the lift delta (difference) for each degree of rotation. This 1st derivative will be the valve's velocity.

From that data, produce the next 2nd order derivative values.

Again, that will be the velocity deltas (differences) for each degree of rotation. This 2nd derivative will be the valve's acceleration.

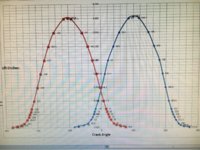

You'll end up with a chart like this:

Ideally, you want all lash taken up and valve movement commencing at the precise point that velocity and acceleration begin their rise (about at -68° in the above chart). Whatever the lift value is at that point is the target lash (looks like about 0.009" on that chart). See if your findings match that of the cam grinder's and other's recommendations.

If the lash is set looser than that, there's the risk of excessive valve train hammering.

If the lash is set tighter than that, you'll have a valve setting off the seat, leaking, and not providing any benefits (engine breathing-wise).

For more info, Google: "camshaft entrance ramps".

Then, read those entries that discuss the issue "No cam card", for those who are trying to set up valve lash on undocumented cams...