-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nice fab work there. Will be nice once all done up! Wish I could weld...may be a future goal!

Steveair2

XS650 Addict

Thanks Superjet. You should learn to weld, it is a very rewarding hobby to fabricate and weld. I've been gas welding everything for years.

I did find a good deal on a Lincoln 175 tig welder, but I have yet to get power to it and for now continue to gas weld. It's what I'm comfortable with anyway.

So I was planning on getting a lot done this weekend on my project. Yesterday morning two of my dogs Muffin and Lady attacked my favorite dog Coco.

My wife managed to save her but she was torn apart. We rushed her to the vet and had her put back together. Then while I was at work yesterday night

my wife found a new home for Muffin and Lady. Coco died this morning and we buried her in the back yard at 4:30am this morning.

All three of my dogs are gone now. I'm laid up in bed very sad and depressed at the moment. It will take time for this to heal. SUCKS BAD!

Rest in piece baby Coco, I love you so much.

I did find a good deal on a Lincoln 175 tig welder, but I have yet to get power to it and for now continue to gas weld. It's what I'm comfortable with anyway.

So I was planning on getting a lot done this weekend on my project. Yesterday morning two of my dogs Muffin and Lady attacked my favorite dog Coco.

My wife managed to save her but she was torn apart. We rushed her to the vet and had her put back together. Then while I was at work yesterday night

my wife found a new home for Muffin and Lady. Coco died this morning and we buried her in the back yard at 4:30am this morning.

All three of my dogs are gone now. I'm laid up in bed very sad and depressed at the moment. It will take time for this to heal. SUCKS BAD!

Rest in piece baby Coco, I love you so much.

Last edited:

Sorry to hear that news Steveair2. That does indeed suck big time. BTDT more than once. There is that old saying 'time heals'.....but it's never quite the same eh?

I wish you all the best.

Take care of yourself and that special lady.

I wish you all the best.

Take care of yourself and that special lady.

Steveair2

XS650 Addict

Thanks much robinc, it's been a very rough week for us. We were not fortunate enough to have children, our dogs served as them.

We would not go to sleep at night unless all three were in bed with us. The house is quite now and we don't like it.

I'm spending my day off today out in the garden, and cleaning up house and shop.

We would not go to sleep at night unless all three were in bed with us. The house is quite now and we don't like it.

I'm spending my day off today out in the garden, and cleaning up house and shop.

Rider_onthe_Storm

XS650 Member

...what if your dope was on fire?

Impossible, sir. It's in Johnson's underwear.

Impossible, sir. It's in Johnson's underwear.

Steveair2

XS650 Addict

After my garden escapade and a short visit to Coco's grave, I was able to get some work done on my switch housing. The piece I cut to finish the housing fit perfect without any trimming or filing! I did have to add two slight notches at the front edge. I dropped it while painting it and got some dog hair in the finish. I dried the housing in the toaster oven then went over it with scotch bright to get the hair off. Ended up giving it a cool weathered look. May keep it.

Last edited:

Steveair2

XS650 Addict

I couldn't find a commercially made terminal block that would work for me so I decided to make my own.

Attachments

Steveair2

XS650 Addict

The electrical bracket is evolving slowly. I welded in some 10-32 nuts for the tach/hour meter, and a stud for my capacitor.

I decided I made my terminal studs too long so I'll need to make some new ones. At this point the part is looking good, and I'm going slow so that I don't screw it up before it's finished.

I decided I made my terminal studs too long so I'll need to make some new ones. At this point the part is looking good, and I'm going slow so that I don't screw it up before it's finished.

Attachments

Steveair2

XS650 Addict

Steveair2

XS650 Addict

Steveair2

XS650 Addict

Steveair2

XS650 Addict

Great fab skills, and sticktoitiveness!

will keep an eye on this!

will keep an eye on this!

Steveair2

XS650 Addict

Hello group, it looks like this project rotated back into the active.

I had a hard time working for Pepsico. Everyone was always pissed off at each other. In the year I was there I saw twelve mechanics come and go and five supervisors as well. It was the worst job I ever had, and if I happen to run into some of them in the future, I will kick their ass with no hesitation.

I left there the day I got back from Sun-N-Fun last year and found a good job working as a mechanic for Dallas County.

Luckily I'm considered an essential employee and have been working through the Corona BS.

Last week I got back to it. I'm working on the rear brakes. It would have been a pain in the ass to get my caliper to the machine shop and back, so I devised a way to do it myself. My hacksaw rode on the 3/4" steel tubing, the tubing sorta rolled back a forth. I then filed it smooth and polished with various grades of sandpaper. I couldn't believe how well it fit. I just need now to shorten the right axle spacer a little bit.

View attachment 164639

View attachment 164639  View attachment 164634

View attachment 164634

I had a hard time working for Pepsico. Everyone was always pissed off at each other. In the year I was there I saw twelve mechanics come and go and five supervisors as well. It was the worst job I ever had, and if I happen to run into some of them in the future, I will kick their ass with no hesitation.

I left there the day I got back from Sun-N-Fun last year and found a good job working as a mechanic for Dallas County.

Luckily I'm considered an essential employee and have been working through the Corona BS.

Last week I got back to it. I'm working on the rear brakes. It would have been a pain in the ass to get my caliper to the machine shop and back, so I devised a way to do it myself. My hacksaw rode on the 3/4" steel tubing, the tubing sorta rolled back a forth. I then filed it smooth and polished with various grades of sandpaper. I couldn't believe how well it fit. I just need now to shorten the right axle spacer a little bit.

View attachment 164639

View attachment 164639  View attachment 164634

View attachment 164634Attachments

Welcome back!

Steveair2

XS650 Addict

Thanks, lakeview. I'm currently on a seven day workweek. I'm at work now from 7 pm to 7:30 am. I didn't get much done this week.

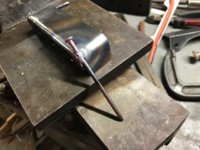

I started making some master cylinder mounting brackets. These bullet mounts I ordered from Bung King are nice, but I'm having a hard time welding them.

I've been using a propane torch to try and get them up to temperature for welding. I should use MAP gas but propane is all I have.

I'm gas welding everything on this project. I keep the propane torch on the bullet during the welding process. The stainless block the bullet is bolted to is drawing much heat from the welding. It's bolted to the block for alignment purposes.

I started making some master cylinder mounting brackets. These bullet mounts I ordered from Bung King are nice, but I'm having a hard time welding them.

I've been using a propane torch to try and get them up to temperature for welding. I should use MAP gas but propane is all I have.

I'm gas welding everything on this project. I keep the propane torch on the bullet during the welding process. The stainless block the bullet is bolted to is drawing much heat from the welding. It's bolted to the block for alignment purposes.

Last edited:

Steveair2

XS650 Addict

I got a little done tonight. I welded the second master cylinder mount up. I managed to get this one hotter so the welding went a little better.

Still looks like shit. I welded them three-quarters of the way around and brazed the edge near the bolt hole. I brazed it because I wasn't sure if I could weld it without screwing it up. I'm still going to need to clean them up with a grinding drum and maybe a bit of Bondo. What shit? I should be better than this.

I also bought some bolts for my handlebars. The only place I could find what I needed fast was off Ebay. I needed two 1/2" x 6" stainless socket head bolts.

I found a pack of four on eBay and it ended up costing thirty-eight dollars for them. If anyone needs two of these bolts, I have two for sale.

That yellow stuff in the first picture I think is chrome that burnt off my vice grips clamp durring welding. The second picture is brazing rod.

Still looks like shit. I welded them three-quarters of the way around and brazed the edge near the bolt hole. I brazed it because I wasn't sure if I could weld it without screwing it up. I'm still going to need to clean them up with a grinding drum and maybe a bit of Bondo. What shit? I should be better than this.

I also bought some bolts for my handlebars. The only place I could find what I needed fast was off Ebay. I needed two 1/2" x 6" stainless socket head bolts.

I found a pack of four on eBay and it ended up costing thirty-eight dollars for them. If anyone needs two of these bolts, I have two for sale.

That yellow stuff in the first picture I think is chrome that burnt off my vice grips clamp durring welding. The second picture is brazing rod.

Last edited:

Steveair2

XS650 Addict

I'm slow this week. It's my week to work the midnight shift. I also had to replace the motor on my compressor.

I've been using the bandsaw at work each night to cut the pieces needed for my handlebar risers.

Today after work I experimented making a tight radius bend on my next set of mockup handlebars.

Since I left my chop saw at my friend's house an hour away, I had to use my hacksaw. The kerf on my saw was too thin.

I figured out I could put two hacksaw blades on my saw enlarging the kerf. Seven slices a quarter-inch apart gave the bend I

wanted. I'm using electrical conduit for my mockup handlebars. With the short lengths needed for the bars, the electrical conduit would probably be plenty strong enough. But since the ID of the conduit is too large to fit the internal sleeves I'm using to mount my internal throttle and grips, I'll go ahead and use the 4130 I ordered. Also, since I lost all my dogs last year, I got a new one. That's Cooper on the right. He's playing with my next door neighbors dog Foxy.

They love each other.

I've been using the bandsaw at work each night to cut the pieces needed for my handlebar risers.

Today after work I experimented making a tight radius bend on my next set of mockup handlebars.

Since I left my chop saw at my friend's house an hour away, I had to use my hacksaw. The kerf on my saw was too thin.

I figured out I could put two hacksaw blades on my saw enlarging the kerf. Seven slices a quarter-inch apart gave the bend I

wanted. I'm using electrical conduit for my mockup handlebars. With the short lengths needed for the bars, the electrical conduit would probably be plenty strong enough. But since the ID of the conduit is too large to fit the internal sleeves I'm using to mount my internal throttle and grips, I'll go ahead and use the 4130 I ordered. Also, since I lost all my dogs last year, I got a new one. That's Cooper on the right. He's playing with my next door neighbors dog Foxy.

They love each other.

Last edited:

Steveair2

XS650 Addict

Midnight shift is rough for me. I stayed awake from 4 pm Thursday to 9 am Saturday morning, won't do that again.

Sunday, I was making another set of mock up handlebars but stopped. I decided to just make a set of handlebars to get the bike done.

If I want to change them later I can. I also filled my fuel tank with vinegar. Getting ready to Red-kote it.

Sunday, I was making another set of mock up handlebars but stopped. I decided to just make a set of handlebars to get the bike done.

If I want to change them later I can. I also filled my fuel tank with vinegar. Getting ready to Red-kote it.

Similar threads

- Replies

- 20

- Views

- 5K