Steveair2

XS650 Addict

I hope everyone is doing okay through the plandemic. I've been lucky enough to stay employed through the whole ordeal. I coated the inside of my fuel tank with two coats of Redkote Saturday.

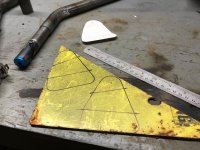

Worked on handlebars tonight. I cut nine slots, used steel rule to measure depth, and measured back side to 5/8".

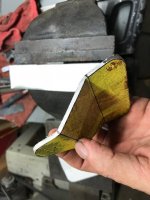

Used a can of acetone to prop the bend during welding for safteys sake. Really just for fun, or it worked good because it would deform to needed angle.

Worked on handlebars tonight. I cut nine slots, used steel rule to measure depth, and measured back side to 5/8".

Used a can of acetone to prop the bend during welding for safteys sake. Really just for fun, or it worked good because it would deform to needed angle.