Port

XS650 Addict

I learned two bad things today and i'm going to ask some (possibly) obvious question just to get your opinions

The PO broke off a sump plate bolt. The on on the front edge on the right side. I could get it out but it would suck. I don't want to pull the engine and i don't have a drill i could get at it good with. I could find someone to weld on a nut. This is my preferred option but i don't have someone to do it for me or a welder. My question is:

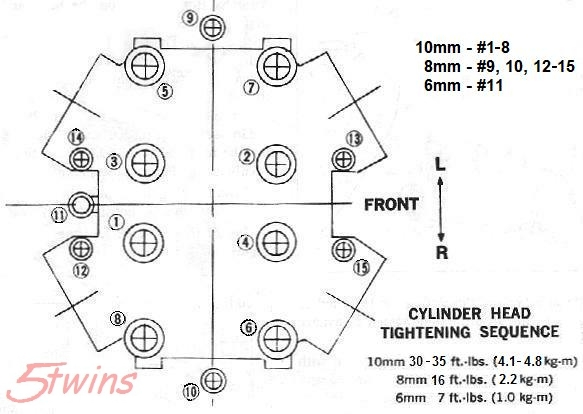

The PO stripped the threads out of the head for one of the six 8mm bolts on the head (bolt #13).

I realized this while re-torquing the head due to a front side oil leak. The torque sheet marks it out for 16 ft.lbs it only took 10. The other 5 took the 16 ft.lbs.

The PO broke off a sump plate bolt. The on on the front edge on the right side. I could get it out but it would suck. I don't want to pull the engine and i don't have a drill i could get at it good with. I could find someone to weld on a nut. This is my preferred option but i don't have someone to do it for me or a welder. My question is:

- Will it leak if i try and run it with just the 5 good bolts?

The PO stripped the threads out of the head for one of the six 8mm bolts on the head (bolt #13).

I realized this while re-torquing the head due to a front side oil leak. The torque sheet marks it out for 16 ft.lbs it only took 10. The other 5 took the 16 ft.lbs.

- How bad is this?

- Is there a danger of running it as is?

- Will it still leak?

- Can i fix it?

- Can i fix it without pulling the engine (i don't have a space for that right now)

- Is this a valid option: https://www.grainger.com/ec/pdf/Loctite-Form-A-Thread-Data-Sheet.pdf

Last edited: