I put my bike away for the winter with a bad case of carburettor flu. Gasoline was poring out of one of my carbs. Bike was running fine. Took the carbs of and checked and cleaned them. Replaced all hoses as well. I put the carbs back on the bike today and now it's blowing air out through the carbs and sucking air in through the exhaust. The valves are moving freely. I did turn the engine over without the cam chain tensioner in because I'm an idiot, but I doesn't look like the timing is of. I will double check the timing tomorrow. Any good ideas on what I have messed up?

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sucking air through exhaust, blowing out through carburettors

- Thread starter Fossi

- Start date

-

- Tags

- carburetors engine

If you're rotating the engine slowly, like with a wrench on the rotor nut, the long duration of the cam timing events can produce mild 'exhaust sucking' and 'carbs blowing' symptoms. That's normal.

If it does that while running, you've got a more serious problem...

If it does that while running, you've got a more serious problem...

I have noticed that happening TwoManyXS1Bs, but this seems different. The bike won't start. The movment of air is when I try to kick start it (No electrical starter) and it seems to be more air than when II turn it with a wrench. I've scratched my head bald trying to figure this out. Ok, ok I was bald to begin with, but still....

Well, it must have something to do with valves opening/closing.

Consider sticking valves, sediment on the seats, barnyard critters camping in there.

Sounds like we need to send you a box of hair.

To re-invigorate the head-scratching exercises...

Consider sticking valves, sediment on the seats, barnyard critters camping in there.

Sounds like we need to send you a box of hair.

To re-invigorate the head-scratching exercises...

angus67

Welder's penetrate deeper!!

loosen the valve adjusters all the way out so the valves are sure to be closed, then see if it still does it. if it still does, either a sticking valve, or valve seats are shot.

I just did a head job on a thumper that did exactly the same. The valve seats were pitted, not sealing. I had them lapped back in for 50$.

I just did a head job on a thumper that did exactly the same. The valve seats were pitted, not sealing. I had them lapped back in for 50$.

So I checked the timing and the pin in the right hand cover is 45 degrees of. So good news is that I know whats causing the problem, bad news is that I don't have my garage any more. Backyard wrenching it is then. Is it in any way possible to fix this without taking the top of? I'm thinking that since I managed to mess it up it should be possible to fix the same way as well

...I did turn the engine over without the cam chain tensioner in because I'm an idiot, but I doesn't look like the timing is of. I will double check the timing tomorrow. Any good ideas on what I have messed up?

You might have a camchain that's so stretched that, with the tensioner removed, it jumped sprocket teeth, and the cam is out-of-time.

Proper fix is top-end teardown, camchain replacement, maybe tensioners.

Band-aid fix would be to remove the tensioner again, followed by carefully rotating the crank to try to get the cam/crank back into time. You've got to really know what you're doing here, understanding crank/cam relationships, timing using just the advancer pin, visualizing the crank sprocket rotating above a dangling camchain, and knowing when to reinstall the tensioner. You'll be wanting to do this with the cam pin vertical, so that the valves aren't sticking out enuff to contact the pistons.

The amount of cam misalignment you're reporting could also mean that a piston/valve impact may have already occurred, bending a valve, which means teardown anyways...

I vent for the band aid fix. Figured it was Fubar anyway and that I Will have to pull the top sometime during this season. Turned it around with a wrench and it kept jumping on tye chain. Lined it up with piston at Tdc and the pin in the CAM axle pointing straight up. Reinstalled the CAM chain tensioner and Turned the engine a couple of times by hand. No ratcheling sounds, no resistance, only good times. Tried to start it and it runs. Doesn't run as good as before but I have a few things to eliminate before I go bananas and take the engine out. Gas is old, carbs needs to be adjusted etc. And Just when I started that Job the throttle wire broke. God damn this old things are a test of ones patience. Any ways, thanks for the help you guys. It's always good to have a place like this to let of sole steam and still get help and advice

I vent for the band aid fix...

You possess great visdom in the vays of the engine.

Glad it worked.

... It's always good to have a place like this to let of sole steam and still get help and advice

Yeah, great bunch of guys in here. An addictive forum...

Sucko Gomez

XS650 Member

angus67

Welder's penetrate deeper!!

Yes get your hands dirty

Sucko Gomez

XS650 Member

Is this going to be a project that an intermediate skill level can tackle? I took it to one shop and they don't want to touch it. I did find someone that will look at it, but I don't want to throw another $300 at nothing. If I do it, any suggestions for a tutorial on how?

180 degrees of shouldt be a problem I think, beeing a parallelle twin and all. Anything in between is a problem. What's the story behind this? Did you screw up the way I did or was is Fubar when you got it? If you messed it up by your self you probably know if you met any resitance when the engine turned. If so the valves may be bent. If not you should consider yourself a luck sob and just try to turn it over with the cam tensioner out till it's in the right position. Being a lucky sob I think I manged to get my engine back to the right timing againg using the band aid method described further up here.

Sucko Gomez

XS650 Member

It turns out the PMA cover had rotated on the shaft, TDC is good all the way through. Today I

1. Checked cam chain tensioner. It was good 1mm in and out.

2. Checked.valve clearance. It was good .004 intake and .006 exhaust.

3. After resetting PMA cover and timed ignition.

4. Synced carbs with the tubing, yardstick and ATF.

They're.set.

5. Ran in circles for four hours trying to set the mixture.

Used the Carb Guide instructions, the Clymer Book on

1978 XS650, the dead cylinder. Got nowhere.

It backfires bad while idling, it blew the carbs off several

times. Coughs fuel and white exhaust out carbs when given

throttle. Very fast ramp up RPM after kick then back down to

a rough idle. It ain't Rocket Surgery. I'm at a loss, am I missing

a step or is it a different issue all together. Thanks for your help.

1. Checked cam chain tensioner. It was good 1mm in and out.

2. Checked.valve clearance. It was good .004 intake and .006 exhaust.

3. After resetting PMA cover and timed ignition.

4. Synced carbs with the tubing, yardstick and ATF.

They're.set.

5. Ran in circles for four hours trying to set the mixture.

Used the Carb Guide instructions, the Clymer Book on

1978 XS650, the dead cylinder. Got nowhere.

It backfires bad while idling, it blew the carbs off several

times. Coughs fuel and white exhaust out carbs when given

throttle. Very fast ramp up RPM after kick then back down to

a rough idle. It ain't Rocket Surgery. I'm at a loss, am I missing

a step or is it a different issue all together. Thanks for your help.

Double check that your PMA rotor's TDC mark is precisely set to piston TDC.

Double check ignition timing.

Careful with the dead cylinder method on a 'wasted spark' ignition. A dangling, ungrounding plug cap can cause dangerously high ignition voltages to arc back inside a coil, ruining it and the electronic ignition.

Double check ignition timing.

Careful with the dead cylinder method on a 'wasted spark' ignition. A dangling, ungrounding plug cap can cause dangerously high ignition voltages to arc back inside a coil, ruining it and the electronic ignition.

I would suggest that you readjust your valve clearances first. lack of clearance and valves not seating properly could well be the main cause of your backfiring and blowback .

Modern thinking is to adjust the valves with more clearance like the early bikes had ie

0.006 inlet and 0.012 exhaust.

There is a very interesting explanation and testing report at Howard's site (Smedspeed) http://www.smedspeed.co.uk/tech.html

Make sure that when you adjust the valve clearances you work on the side of the engine which is at TDC on its compression stroke then rotate the engine so that the other cylinder is at TDC on its compression stroke before adjusting those 2x valves.

Modern thinking is to adjust the valves with more clearance like the early bikes had ie

0.006 inlet and 0.012 exhaust.

There is a very interesting explanation and testing report at Howard's site (Smedspeed) http://www.smedspeed.co.uk/tech.html

Make sure that when you adjust the valve clearances you work on the side of the engine which is at TDC on its compression stroke then rotate the engine so that the other cylinder is at TDC on its compression stroke before adjusting those 2x valves.

Last edited:

Sucko Gomez

XS650 Member

Thanks for the valve info. I'm going to try the pipe cleaner and solvent trick tomorrow. So far I've finally got it to idle, however giving it throttle kills it. The valves are .006 and .012 and I've switched out to 137.5 main jet, kept the 30 pilot jet and gone to #2 from the top on needle jet. I've also ordered a rebuild kit to replace any worn O rings. My next step will be diaphragm then intake boots. I'm using the carb guide for adjustments. Here's the video.

Any help would be appreciated.

your main jet and needle has no bearing on your idle or throttle response off of idle .

Forget the needle and main jet.They only come into play at mid to WOT

Concentrate on the pilot jet ,pilot air jet ,air mixture screw , diaphram air leaks, slides and air leaks around the inlets or from parts of the carbs like the 2x choke assembly bodies. A tiny air leak on one of these gaskets can ruin your idle and throttle response.

Remove your air filters and lift each throttle slide in turn and hold it up . Place your thumb or finger over the diaphram air intake (top opening in the mouth of the venturi)

Release the slide and see how long it takes for the slide to drop.

If there are no leaks around the rubber diaphrams or caps then they should stay up or drop very very slowly. If the slides drop quickly then you need to find the air leaks or you'll never get the throttle response right. If your rubbers are old and nackered like mine were you could try smearing some vasoline around the edges where they seal in the grooves in the caps ...it worked on mine.

Forget the needle and main jet.They only come into play at mid to WOT

Concentrate on the pilot jet ,pilot air jet ,air mixture screw , diaphram air leaks, slides and air leaks around the inlets or from parts of the carbs like the 2x choke assembly bodies. A tiny air leak on one of these gaskets can ruin your idle and throttle response.

Remove your air filters and lift each throttle slide in turn and hold it up . Place your thumb or finger over the diaphram air intake (top opening in the mouth of the venturi)

Release the slide and see how long it takes for the slide to drop.

If there are no leaks around the rubber diaphrams or caps then they should stay up or drop very very slowly. If the slides drop quickly then you need to find the air leaks or you'll never get the throttle response right. If your rubbers are old and nackered like mine were you could try smearing some vasoline around the edges where they seal in the grooves in the caps ...it worked on mine.

Attachments

Sucko Gomez

XS650 Member

I ended up tearing the engine apart and the insides looked like a black valour shirt and I checked the valives for seat, could have lost a whole plate of spaghetti through them. I cleaned that up and took the main jet down to 137. Now I'm just waiting for the gasket kit to come in so I can put it back together. Thank you all for the help, and I'll let you know what happens on the 7th.

Sucko Gomez

XS650 Member

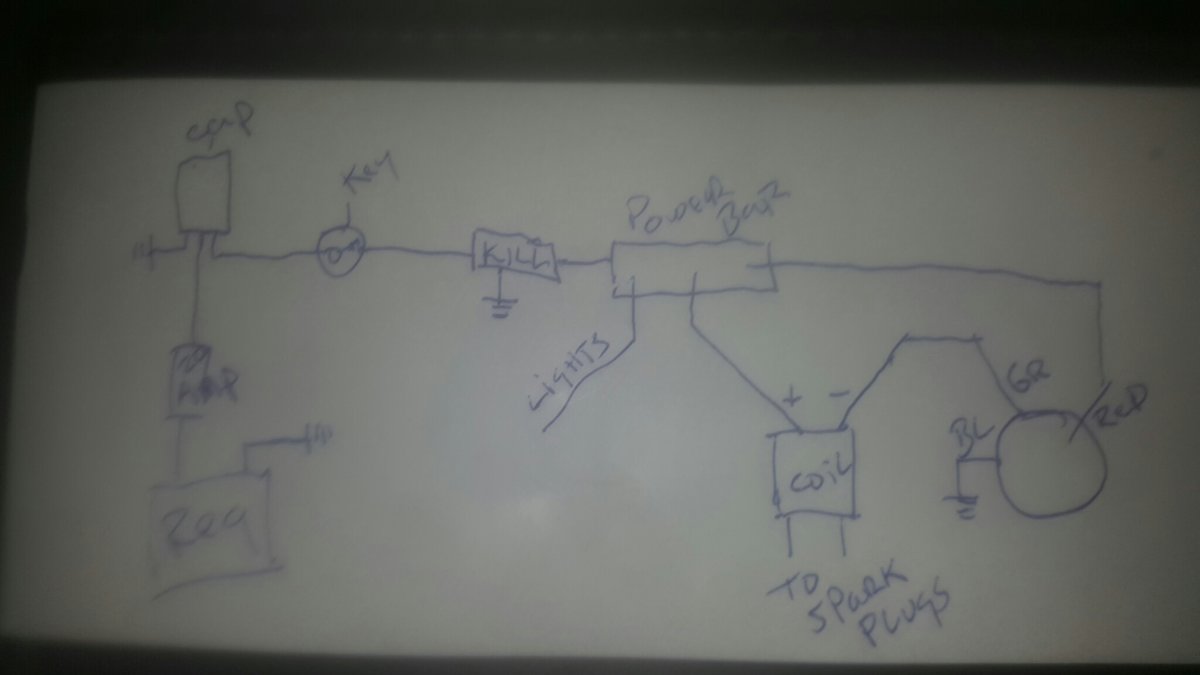

After cleaning the top end out and even running it through the dishwasher so there would be no unsightly spots on my glassware. Replacing 4 broken rings, waiting for 3 wrong sized master links at a week per link, fourth times a charm. I went after the hay bale of wiring, for being so simple there was a ton of wire removed. Here is what I did. I'm running PMA and no battery, the power bar is a brass bar I got at the hardware store so I wouldn't have to splice so many times. Is this correct, I don't want to blow anything trying to start it. Thanks for your help.

Similar threads

- Replies

- 22

- Views

- 510

- Replies

- 5

- Views

- 259

- Replies

- 31

- Views

- 950

- Replies

- 41

- Views

- 1K