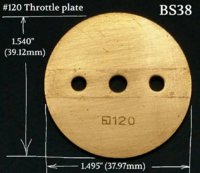

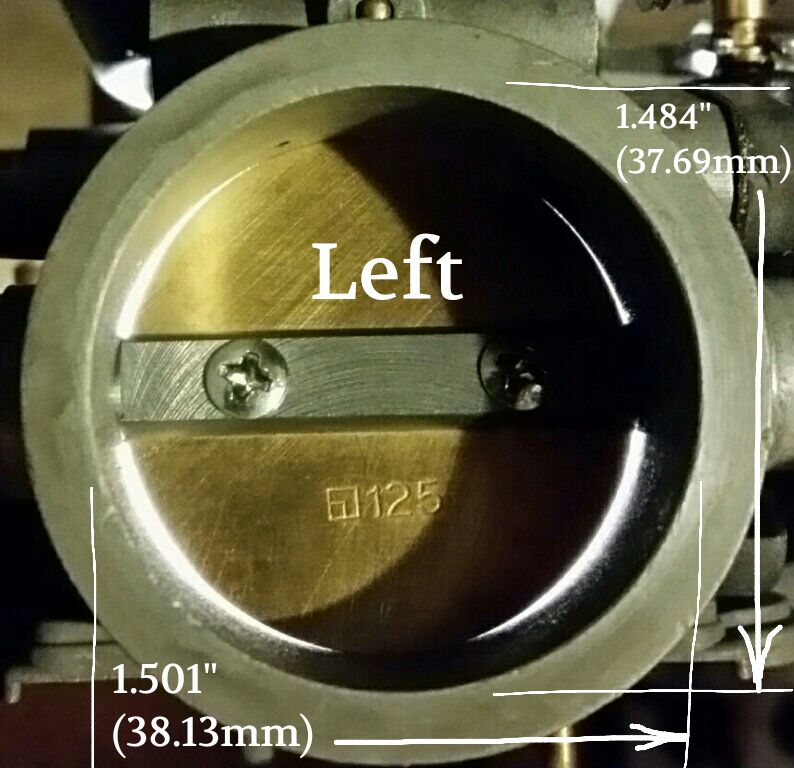

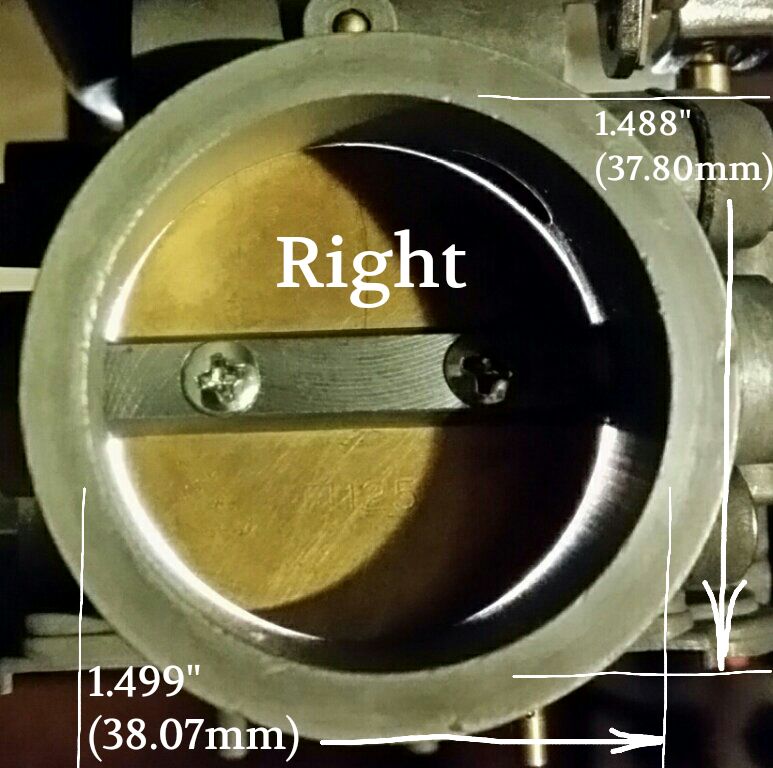

Measuring my XS1B's #125 throttle plates, plus #120 and #135 throttle plates submitted by DogBunny.

Thought I'd share some of this trivia.

Throttle plates are an oval shape, as though they were sliced (sausage style) at an angle through a cylinder.

The width of a throttle plate is the diameter of the cylinder from which the plate is patterned.

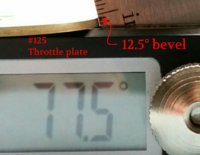

Placed each plate on my digital compass, leaving a tiny sliver of light between the bevel edge and the compass arm.

Measuring the plate height is total height, including opposite bevels.

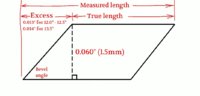

Viewed from the edge, the throttle plate resembles a parallelogram.

To get the true plate height, a bevel protrusion from one end must be subtracted.

All 3 plates are 0.060" thick.

Depending on bevel angle, must subtract 0.013" (for 12.0° & 12.5° bevels), or 0.014" (for 135.0°bevel)

The bevel edges are very slightly rounded, so will add 0.001" adjustment to total height to recapture the edge.

The plate's base cylinder diameter (its width) divided by the true plate height will be the cosine of the bevel angle.

Thought I'd share some of this trivia.

Throttle plates are an oval shape, as though they were sliced (sausage style) at an angle through a cylinder.

The width of a throttle plate is the diameter of the cylinder from which the plate is patterned.

Placed each plate on my digital compass, leaving a tiny sliver of light between the bevel edge and the compass arm.

Measuring the plate height is total height, including opposite bevels.

Viewed from the edge, the throttle plate resembles a parallelogram.

To get the true plate height, a bevel protrusion from one end must be subtracted.

All 3 plates are 0.060" thick.

Depending on bevel angle, must subtract 0.013" (for 12.0° & 12.5° bevels), or 0.014" (for 135.0°bevel)

The bevel edges are very slightly rounded, so will add 0.001" adjustment to total height to recapture the edge.

The plate's base cylinder diameter (its width) divided by the true plate height will be the cosine of the bevel angle.

Last edited: