Looking good.

Hate to throw cold water on anything, my concern is the rear guard mounting.

All rear guards have cracking problems. On the early70-73 guards they would crack where the Bolt from the loop stay fitted and held up the guard.......later ones, (standards), around the taillight/no-plate, bracket mounts where the bolts went through the guard......... the early Specials where the taillight and No plate light mounted to the rear of the Guard and on the edge of the very back end of the guard......later specials would still crack around the no plate light although it was way lighter than the earlier Specials........all these mounting points also had rubber dampers as well.........some one did say these bikes have a vibration problem.

All guards from the Standards and specials fro 74-83 had extra bracing around the bolt holes where the tail lights and no plate light bolts went into the guard and yet they still cracked. The guards were mounted on each side to the frame and these mounting points were heavily strengthened to stop the guard from cracking.

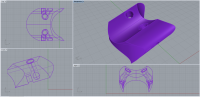

Here is my point........your 2 bolts off the frame need to have extra bracing under the guard and on top of the guard. Ideally some rubber dampers as well. I think that it will crack around those two bolts real quick and if it does happen on a ride it could be quite dangerous having the back of the guard jamming into the tyre.

I'll get some pics of the bracing on the guards i have mentioned so you can see what i am talking about