UncleBuck

XS650 Enthusiast

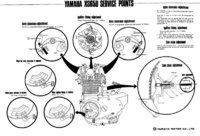

It's actually about 180° away. As best I can figure the PO (everyone's favourite person to blame) had the engine apart, and the rotor didn't get set back to the right position.

Does that even make sense?

I definitely have not been able to start the engine. If I back off the toothed nut holding the points shaft on the the cam shaft, I can adjust the timing until the points separate just about TDC, and I could probably fudge it so they separate back at around the F mark on the rotor (15° BTDC?). However, backing off that nut and trying to adjust things is how I got into this mess in the first place. Wish I'd checked to make sure the pistons were at TDC with an ever-loving straw through the spark plug opening before assuming they were at TDC because the marks said they SHOULD be at there.

Now, I'm pretty sure the right answer is to open things up and make them back to factory.

What kind of mess is this going to be to sort out? I can probably hack my way through this making small adjustments until the bike starts. I'm thinking there's probably a smarter way.

Any thoughts?

Does that even make sense?

I definitely have not been able to start the engine. If I back off the toothed nut holding the points shaft on the the cam shaft, I can adjust the timing until the points separate just about TDC, and I could probably fudge it so they separate back at around the F mark on the rotor (15° BTDC?). However, backing off that nut and trying to adjust things is how I got into this mess in the first place. Wish I'd checked to make sure the pistons were at TDC with an ever-loving straw through the spark plug opening before assuming they were at TDC because the marks said they SHOULD be at there.

Now, I'm pretty sure the right answer is to open things up and make them back to factory.

What kind of mess is this going to be to sort out? I can probably hack my way through this making small adjustments until the bike starts. I'm thinking there's probably a smarter way.

Any thoughts?