kawabunga

XS650 Addict

Hello, new to the forum here. I picked up a '79 XS650 basket case. First off, I'd like to determine exactly which sub-model of XS I have. Engine number is 2F0-173457, according to the tables I found by googling "XS650 identification", I should have an XS-F. Does that sound correct?

My main reason for posting is that I'm having trouble getting the static ignition timing set. I'm following the procedure outlined in the Clymer manual for 1970-1982 650 twins. No matter what I try I am not able to set it to where my test light just comes on at the firing mark on the flywheel.

The bike is a mess, it was not running when I got it and the guy I acquired it from never had it running himself, but supposedly the previous guy did. So, I have no history of the machine and it has been hacked into already.

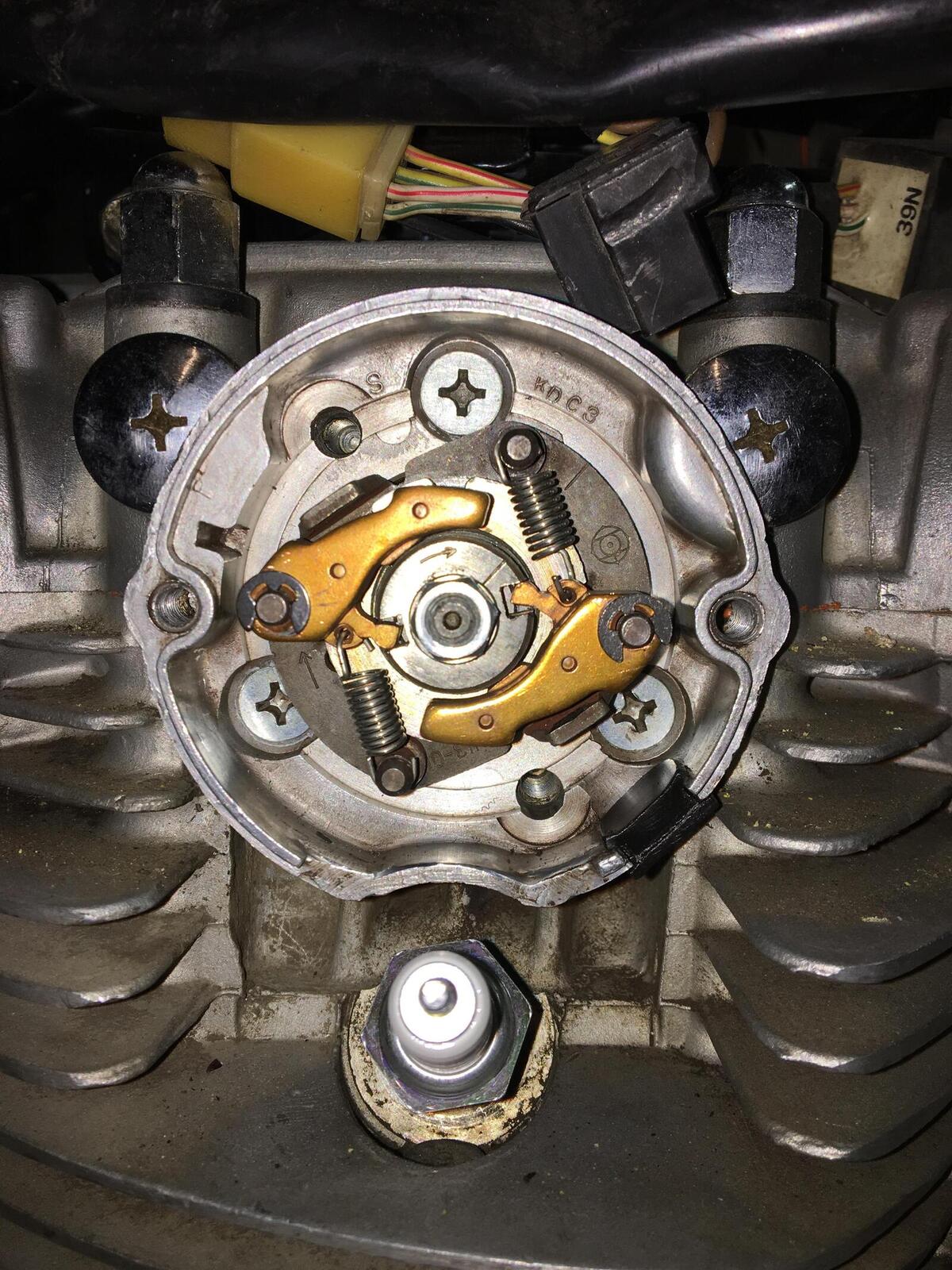

I got it running, it will idle, but it pops and spits a lot while doing so. It doesn't like getting throttle either. I checked/adjusted the valves, intake in the .0025-.003" range and exhaust at .006". New points set to .014", new condensers and new plugs. It has good spark and the carbs are clean. I disassembled and reassembled the auto advance unit and pulled the rod in the cam going to the points cam and attempted rotating it 180 degrees to see if that made a difference, but had no luck.

What am I missing? Is there something could be flipped 180 degrees that would make it impossible to set the static timing? Could the valve timing be off? It currently runs, not well but it does, so I'm not too suspicious of that. I attempted to find thorough instructions for installing the auto advance unit but was unable to, and the manual isn't too clear. Does anyone have a link or know-how on the proper way to install that?

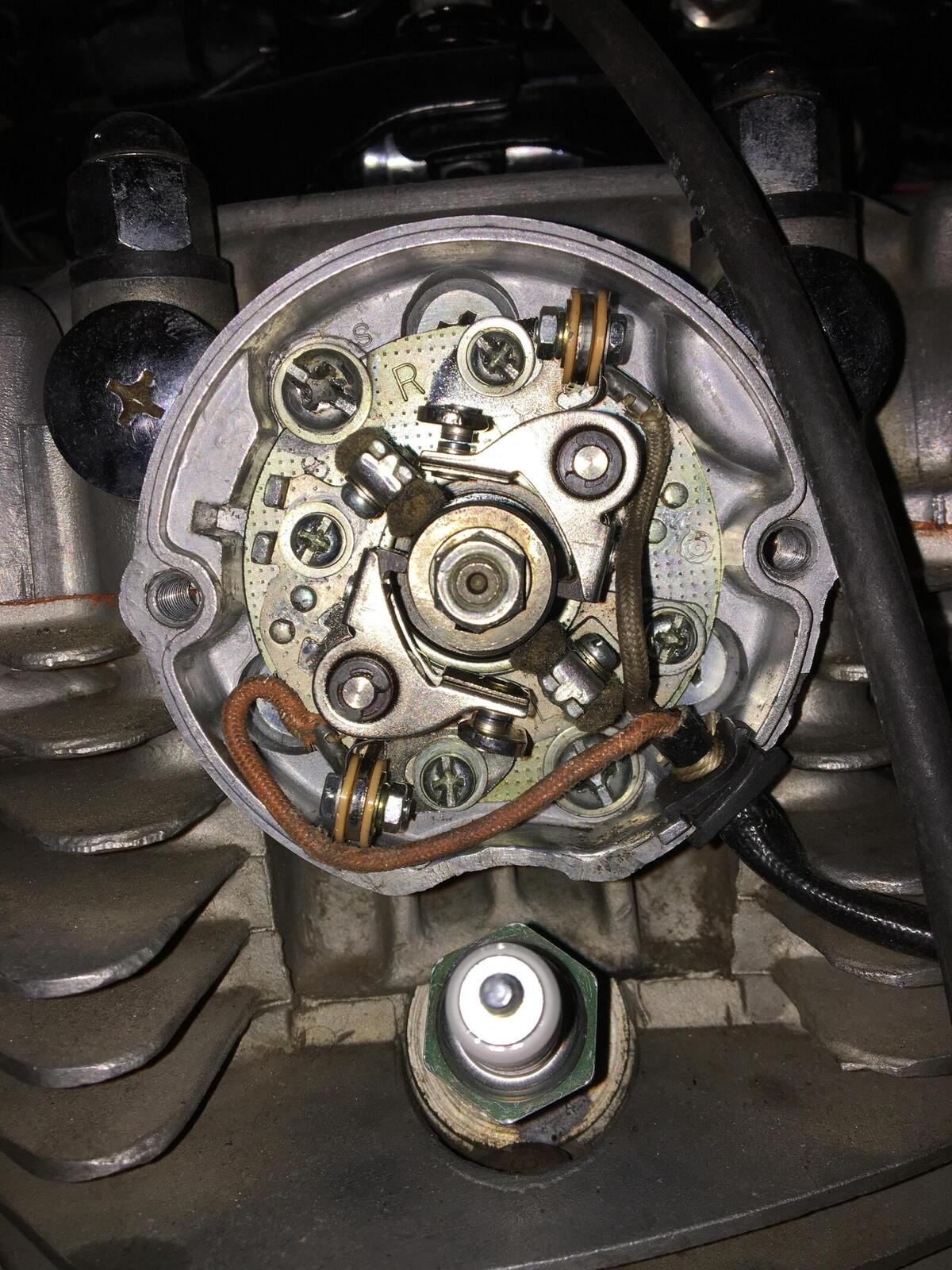

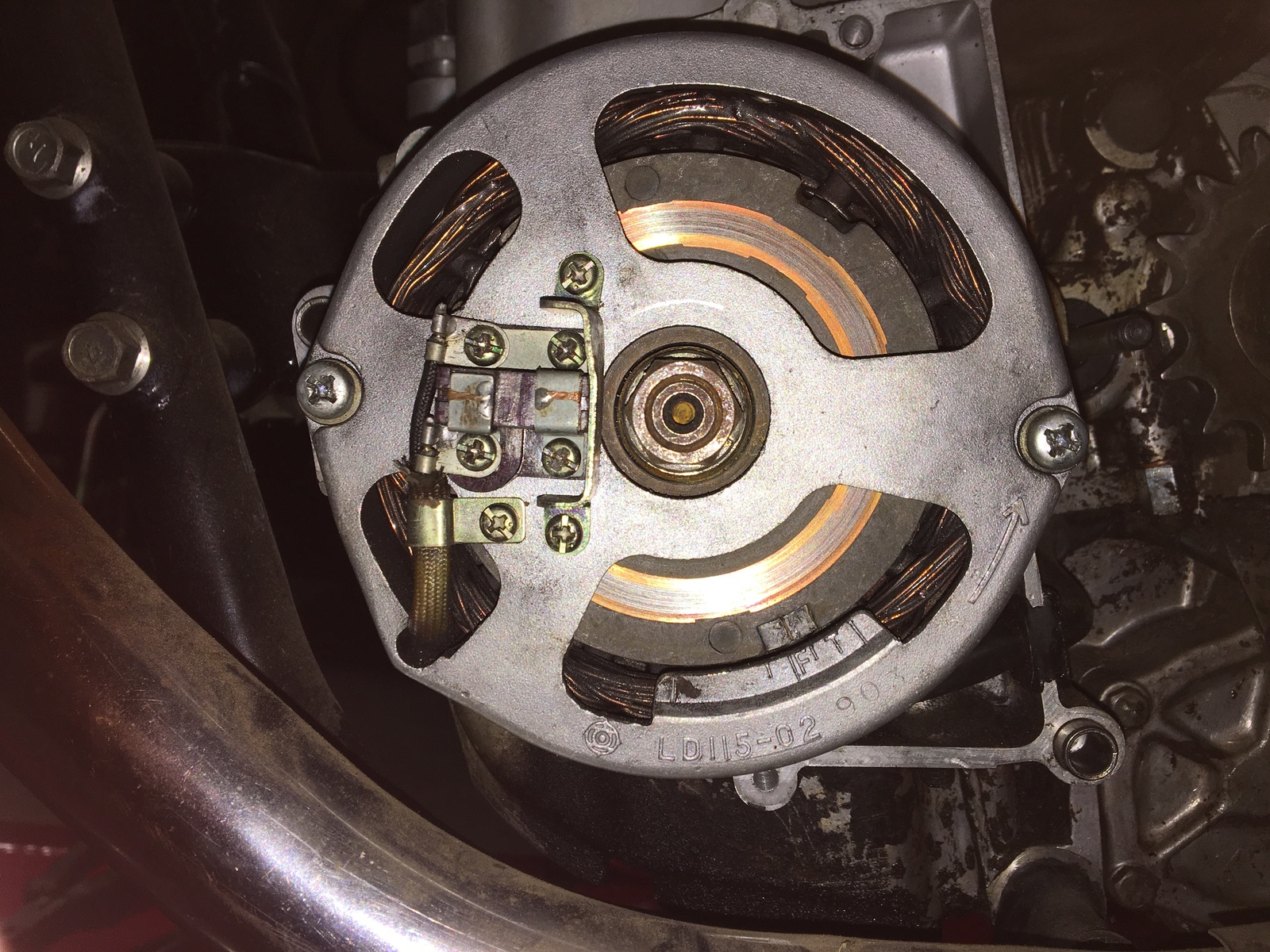

Here's some photos of how it's currently set up. Does anything stand out as wrong?

Thank you in advance for any advice .

kawabunga

My main reason for posting is that I'm having trouble getting the static ignition timing set. I'm following the procedure outlined in the Clymer manual for 1970-1982 650 twins. No matter what I try I am not able to set it to where my test light just comes on at the firing mark on the flywheel.

The bike is a mess, it was not running when I got it and the guy I acquired it from never had it running himself, but supposedly the previous guy did. So, I have no history of the machine and it has been hacked into already.

I got it running, it will idle, but it pops and spits a lot while doing so. It doesn't like getting throttle either. I checked/adjusted the valves, intake in the .0025-.003" range and exhaust at .006". New points set to .014", new condensers and new plugs. It has good spark and the carbs are clean. I disassembled and reassembled the auto advance unit and pulled the rod in the cam going to the points cam and attempted rotating it 180 degrees to see if that made a difference, but had no luck.

What am I missing? Is there something could be flipped 180 degrees that would make it impossible to set the static timing? Could the valve timing be off? It currently runs, not well but it does, so I'm not too suspicious of that. I attempted to find thorough instructions for installing the auto advance unit but was unable to, and the manual isn't too clear. Does anyone have a link or know-how on the proper way to install that?

Here's some photos of how it's currently set up. Does anything stand out as wrong?

Thank you in advance for any advice .

kawabunga