-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Turbo Woody" Bobber Build Yes real wood!

- Thread starter wallywheels

- Start date

-

- Tags

- build

lowliferat

certified hack

Wow! Never seen anything like this build. You have talent. But I guess you already know that. What you do for a living if you don't mind me asking. Work with wood? Maybe?

RpNSht

XS650 Addict

crazy good woodman ship

you think you could make a tank out of wood too? if you seal it using red koat or kreem what would be the difference than alum or steel tank?

you think you could make a tank out of wood too? if you seal it using red koat or kreem what would be the difference than alum or steel tank?

wallywheels

"savage"

Thank you all for the compliments

Lowlife rat I am a career firefighter as well as a call lieutenant on another department and to add to the confusion I am also a firefighter in the Air Force Reserve. On the side I do all my woodworking.

Lowlife rat I am a career firefighter as well as a call lieutenant on another department and to add to the confusion I am also a firefighter in the Air Force Reserve. On the side I do all my woodworking.

wallywheels

"savage"

Just finishing up another two builds and then back to the Turbo project. But I still have a lot to catch up on here of the past build process. The all black bike I built for my G/F so we could ride this year. The other one is a bike I built with almost all leftover parts I call it my budget build its under 500.00 and my goal is to sell all the extra stuff I have around for 500.00 so It will feel like a free bike. I built it to have something else to ride this year if I don't finish the turbo bike. Today I wired the whole bike, I am getting very proficient at it.

Attachments

wallywheels

"savage"

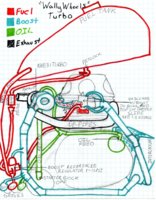

After the turbo was in and plumbed I made some gaskets for it and then went on to making the -AN stainless steel braided lines. For the fuel lines I ran -6AN and for the boost lines and oil feed lines I ran -4AN and for the oil drain I ran -8AN. In order to keep this bike free of a battery I had to design the fuel system so it would run without a fuel pump and to do so I ran a looped system with a check valve so it will stop the fuel from just going back into the tank when the fuel pump is turned on. In order to compensate for the boost pressure over pressurizing the fuel bowl I put in a boost compensated fuel pressure regulator by Mallory. For the fuel pump I ran a generic 30 GPH pump form summit. I welded in two -6AN bungs to the tank and right off the tank used quick disconnects with valves so I can easily unhook my tank. I cant stand leaky petcocks so I opted to not even have one. Here is my original plans I drew for the turbo install and some pics of the AN fittings I used I beleive there was a total of 78 Fittings..

Attachments

wallywheels

"savage"

I didnt know where I wanted to mount my gauges and one day I was holding up some copper for the intercooler and I had it up by the tank. Just then I started measuring ID on the copper and the OD on some gauges and found some to fit perfectly into the elbows. In the upper left is my ATF Gauge, Lower left is my Boost pressure, Upper right is oil psi, Lower right is Fuel pressure The three small gauges are 1.5" and the larger gauge is a 2" I think once I do final paint and polish it is really going to pop. Plus the gauges are in a great place to see while riding instead of being hidden down on the side of the bike or something..

Attachments

wallywheels

"savage"

For my oil feed to the turbo I drilled a plug out of the clutch cover where the oil pump come out to the motor after the filter. I ran -4AN lines to it with a tee to a 0-60 psi gauge. I tapped the side cover with a 1/4"NPT tap and put on a 90Degree 1/4"NPT to -4AN adaptor. For the oil drain I disassembled a bad starter I had and used the sealing plate as a location to tap in a drain line. Using a 3/4"NPT tap I tapped the block off plate where the starter bendix used to protrude. Than I put in a 3/4"NPT to -8AN adaptor and ran a line from the Oil drain on the turbo to the starter block off plate.

Attachments

wallywheels

"savage"

In order to stop all this speed yeah right. I decided to incorporate dual Brembo Ducati brakes. I summoned Pandemonium for the adaptor kits and calipers along with a matching master cylinder. The adaptors fit flawlessly after I realized I needed the later model Rotors so I went out to the garage and took 2 off of parts bikes I have. I then sat down for a few hours and came up with a design that on paper looked great but once I started drilling realized it was a bit elaborate. Anyways I stuck with it and it came out decent I decide I did not need to worry about drilling off to much surface area as I have dual rotors to make up for that. I think it looks incredible and cant wait to see it with the redone rims spokes and new tires. I drilled the rotors to match mirrored and so they appeared to spin in the right direction.

yeah right. I decided to incorporate dual Brembo Ducati brakes. I summoned Pandemonium for the adaptor kits and calipers along with a matching master cylinder. The adaptors fit flawlessly after I realized I needed the later model Rotors so I went out to the garage and took 2 off of parts bikes I have. I then sat down for a few hours and came up with a design that on paper looked great but once I started drilling realized it was a bit elaborate. Anyways I stuck with it and it came out decent I decide I did not need to worry about drilling off to much surface area as I have dual rotors to make up for that. I think it looks incredible and cant wait to see it with the redone rims spokes and new tires. I drilled the rotors to match mirrored and so they appeared to spin in the right direction.

yeah right. I decided to incorporate dual Brembo Ducati brakes. I summoned Pandemonium for the adaptor kits and calipers along with a matching master cylinder. The adaptors fit flawlessly after I realized I needed the later model Rotors so I went out to the garage and took 2 off of parts bikes I have. I then sat down for a few hours and came up with a design that on paper looked great but once I started drilling realized it was a bit elaborate. Anyways I stuck with it and it came out decent I decide I did not need to worry about drilling off to much surface area as I have dual rotors to make up for that. I think it looks incredible and cant wait to see it with the redone rims spokes and new tires. I drilled the rotors to match mirrored and so they appeared to spin in the right direction.

yeah right. I decided to incorporate dual Brembo Ducati brakes. I summoned Pandemonium for the adaptor kits and calipers along with a matching master cylinder. The adaptors fit flawlessly after I realized I needed the later model Rotors so I went out to the garage and took 2 off of parts bikes I have. I then sat down for a few hours and came up with a design that on paper looked great but once I started drilling realized it was a bit elaborate. Anyways I stuck with it and it came out decent I decide I did not need to worry about drilling off to much surface area as I have dual rotors to make up for that. I think it looks incredible and cant wait to see it with the redone rims spokes and new tires. I drilled the rotors to match mirrored and so they appeared to spin in the right direction.Attachments

plattey

XS650 Addict

Wow! Great workmanship on the bike man! This is a really great build!

Focusinprogress

XS650 Addict

this bike is all sorts of awesome.

wallywheels

"savage"

What are peoples thoughts on carburetor vs fuel injection and if carburetor which one would you suggest for a turbo application my VM36 round slide is not cutting it so back to the drawing boards on fuel delivery?

wallywheels

"savage"

Ok a few other builds have gotten off the lift and now I am back to the one that counts. I have decided to part together a fuel injection system. My friend is giving me some parts so we will see what I get and where I am going from there unfortunately this means I will have to run some sort of tiny compact battery in order to run the fuel injection for start ups unless I can devise a plan to still run without it.. any thoughts please chime in??? I am getting in way over my head as usual but I would love to see this thing run well instead of how it sits now. I am at an advantage because I already have the two to one intake for the injection module. I also switched to a Pamco ignition but have not tried running it with it yet.

wallywheels

"savage"

Ok life is slowing down winter is on the way this bike needs to be finished by next spring it will have been a 4 year project by then. I am going to New Hampshire on monday to pick up fuel injection parts I will post pics of setup as soon as I get my hands on it. If anyone has any tips with fuel injecting these puppies i am open to suggestions. I am just finishing up a CB750 build...

Attachments

RockingThePartyDJ

XS650 Obsessed

I agree with the earlier comment from JDizon its like a Steampunk kinda look with the engine is the first thing i thought when i saw the copper and then it was a New Yankee workshop kinda thing man Norm Abrahms would be ooh 'in and ahh 'in because man I sure am all i can say is "Wow Impressive" and what a creative use of various materials.

Rock On Man!!!!

Rock On Man!!!!

rusty rocket

XS650 Junkie

Are you worried about the wood cracking with the vibration these old bikes have? Im a trim carpenter and know that hardwoods(ant wood actually) will crack and split. Looks way cool man.

rusty rocket

XS650 Junkie

Sorry I meant to say any wood not ant wood.Are you worried about the wood cracking with the vibration these old bikes have? Im a trim carpenter and know that hardwoods(ant wood actually) will crack and split. Looks way cool man.

wallywheels

"savage"

I have put a lot of thought into the wood cracking thing. What I came up with is the wood is mounted to metal via silicone allowing it to expand and contract but it should keep it rigid enough to not shake and split time will tell once I re-phase it will take a lot of the vibrations out as well. Thx for the compliments

rusty rocket

XS650 Junkie

Sounds like a good idea. Im a hot rodder also, so ive always in the back of my mind wanted to build a woody.I have put a lot of thought into the wood cracking thing. What I came up with is the wood is mounted to metal via silicone allowing it to expand and contract but it should keep it rigid enough to not shake and split time will tell once I re-phase it will take a lot of the vibrations out as well. Thx for the compliments

Similar threads

- Replies

- 785

- Views

- 81K