I know this isn't an XS650, but similar BS38 carbs and looking for advice. I couldn't pass up a 1979 XS1100 for $200 with full Vetter fairing and hard cases. Haven't decided on whether to restore or part it out. Engine has good compression and spark so decided to tear into rebuilding carbs. The P.O. cranked all four pilot screws in so hard all needles are broken off and jammed bad into each carb. Tried tapping the broken end out using a 90 degree pic to no avail. Is the only option to drill or will that bugger em up bad? I have small jeweler drill bits but no drill chuck small enough. Are these carbs now toast? Any suggestions?

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Twisted off pilot screw(ed?)

- Thread starter 2XSive

- Start date

-

- Tags

- pilot screw

I'm thinking a jack inside the throat. Does the tip stick out like it does on a seated BS34 idle screw?

Yeah, three of the carbs have the needle tip sticking inside the throat. One is flat in the hole from me trying to tap it back through. I can take more pics if it'd be helpful. What sort of jack are you thinking of?

Throttle shafts coming out?

I'll draw up a couple ideas in the morning,

I could use something a bit smaller than that, lol. Yes, I'll pull throttle shafts to put in new seals. After you mentioned the jack, I thought of a small bolt with a nut on one end, but getting a push-pin aligned with that tip will be a challenge while trying to expand the "jack". Appreciate the advice!

Typical shop air is 100 psi. I'm guessin' the diameter of that tip is about a tenth of an inch... or less?what about a strong air hose?

Lessee..... π x r² gives us about .008" of area.... times 100 psi. So we'll apply less than a pound of force to the pin with shop air. I don't think that's gonna do it.

I'd soak it with penetrating oil, and heat the area, then try to gently tap or push it out. A large diameter deep socket or short length of pipe just slightly smaller than the carb bore stuck in there and tapped on may do the trick. Or if the size is just right, just slightly smaller than the bore, you may be able to lever down on it, or just rock it up and down and "lever" the broken point out.

I tried multiple things with my buddies xs750 carbs to get the air fuel mix screw tip out and in the end got some teeny tiny drill bits to drill out the soft brass. It actually was easier than I expected. The xs750 fuel mix Screw looked identical to yours.

Took a look and yes aluminum expands about 15-20% more than brass so heat is a bonus.

https://www.engineeringtoolbox.com/thermal-expansion-metals-d_859.html

If you have the carbs fully stripped a 300 degree oven might be a good thing.

Otherwise a heat gun with some caution.

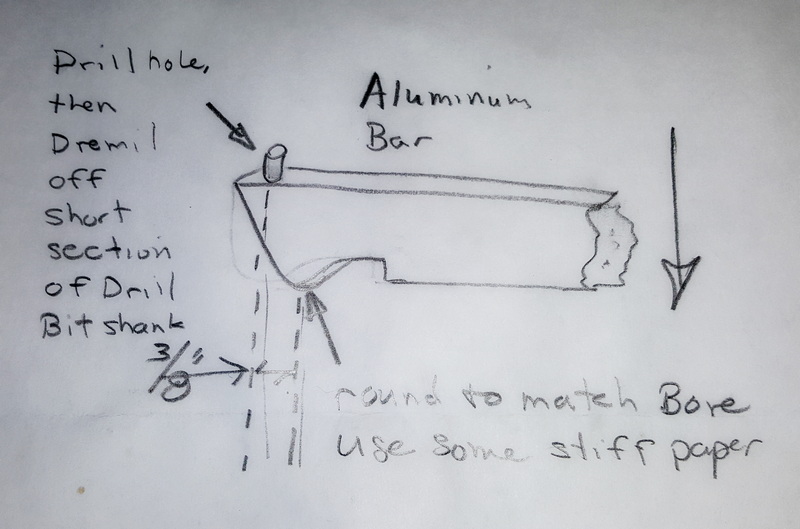

Here's the mark 1a idea.

stiff paper to prevent marring the carb bore

pin about 3/8" proud of the top of the bar so you can see to get it lined up on the screw tip.

hint: to make the pin just the right size, chuck it in a drill then spin while grinding a reduced section at the end.

get the carb body in a vice or such so you have a stable platform. load up the bar with hand pressure then light taps near the end with a small hammer to shock the screw tip loose.

Look up some jetmechmarty posts on XS1100 carbs, there are some gotchas, about carb year vs. jets used.

https://www.engineeringtoolbox.com/thermal-expansion-metals-d_859.html

If you have the carbs fully stripped a 300 degree oven might be a good thing.

Otherwise a heat gun with some caution.

Here's the mark 1a idea.

stiff paper to prevent marring the carb bore

pin about 3/8" proud of the top of the bar so you can see to get it lined up on the screw tip.

hint: to make the pin just the right size, chuck it in a drill then spin while grinding a reduced section at the end.

get the carb body in a vice or such so you have a stable platform. load up the bar with hand pressure then light taps near the end with a small hammer to shock the screw tip loose.

Look up some jetmechmarty posts on XS1100 carbs, there are some gotchas, about carb year vs. jets used.

Thanks guys for the tips and recommendations. I also did some more digging this morning and this person put carbs in the freezer and then used a push pin. http://www.xs11.com/forum/showthread.php?t=23004

Think I'll try that approach first. Nothing is usually that simple with these old bikes, but we'll see. I better get going before the boss wants to look in the freezer for dinner tonight.....

Think I'll try that approach first. Nothing is usually that simple with these old bikes, but we'll see. I better get going before the boss wants to look in the freezer for dinner tonight.....

Well push pin freezer method was too good to be true. Heat method next. I knew these were going to be an issue. Each screw was completely bottomed out tight. What are people thinking when they just start cranking screws tight like this on carbs, as if it'll fix a leaking float and keep gas from pouring out of the carbs.

Here's a thought... take a pair of cheap OD snap ring pliers. Cut the pin off one side and smooth roughness. Heat the other side cherry red and bend it 90° so it's facing straight out. Quench in oil and there ya be.

Well, finally achieved success! Thanks, all, for the tips. After removing the throttle shafts and seals I then heated the area up good and hot with a heat gun. Was then able to use a push pin and hold it with a pair of pliers, and then used a 1" bar to get good perpendicular leverage. Didn't take much force and the tips popped out. You guys were right....heat is the way to go. I couldn't figure out how cooling these in the refrigerator would help, given what Gary said re the rate of expansion between both metals. Pics attached in the event they help if anyone else runs into this issue. Now, time to order new shaft seals and pilot screws, etc. Will see if I can get this XS1100 running and determine if it's worth restoring. Will post up other pics soon. Thanks again everyone! Love this forum.

Attachments

Good job!

A push pin. Whooda thunk it.....