SlowMaintenance

'76 XS650 Chopper

Hey guys, running a 2-1 intake with a Mikuni VM36. Carb is brand new, I've cleaned out the jets several times and can see through them. Brass as follows

22.5 pilot

190 main

6f9 needle with circlip middle slot.

159, p-8 needle jet.

Mix screw out 3/4 turn from seat

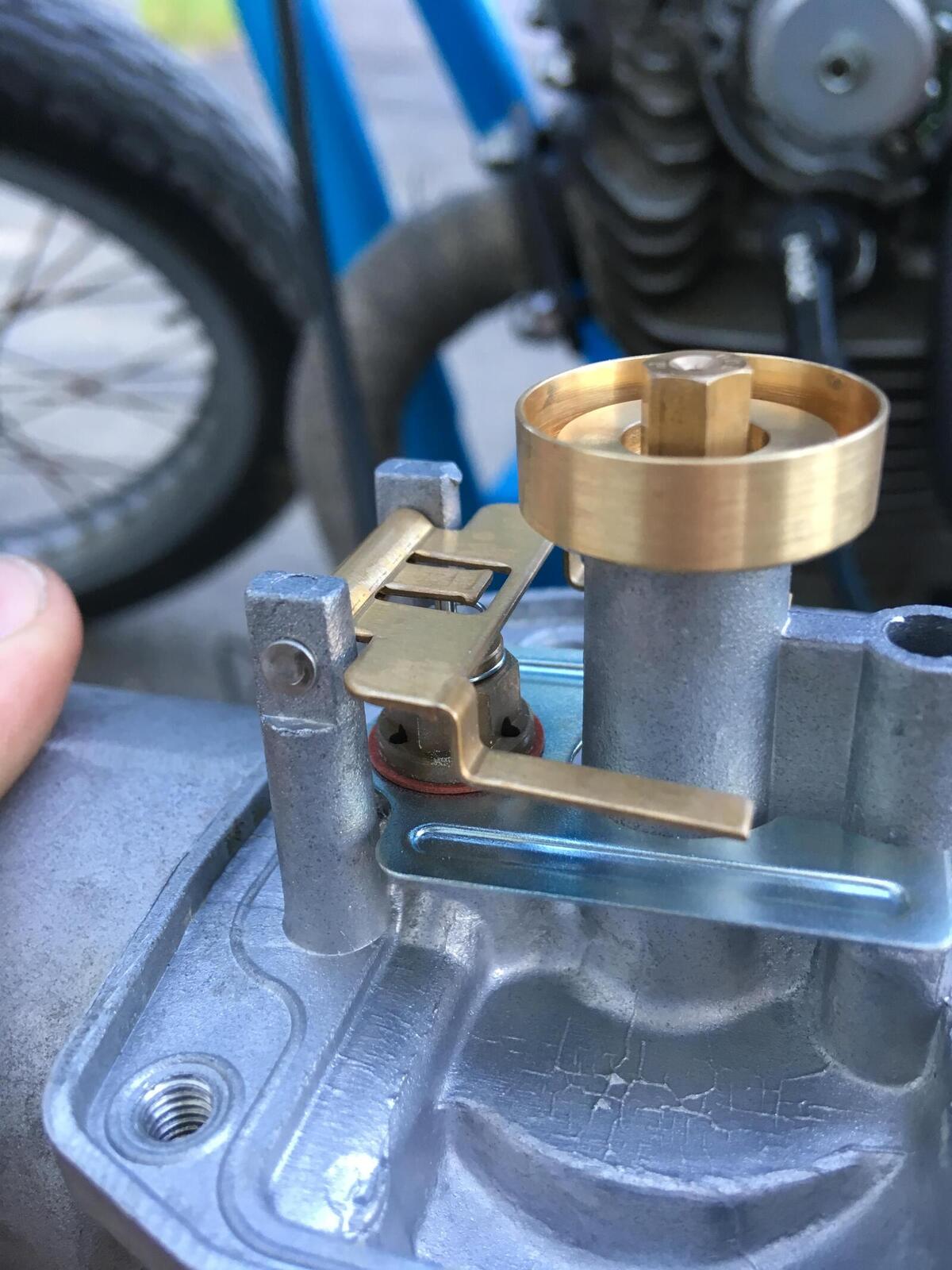

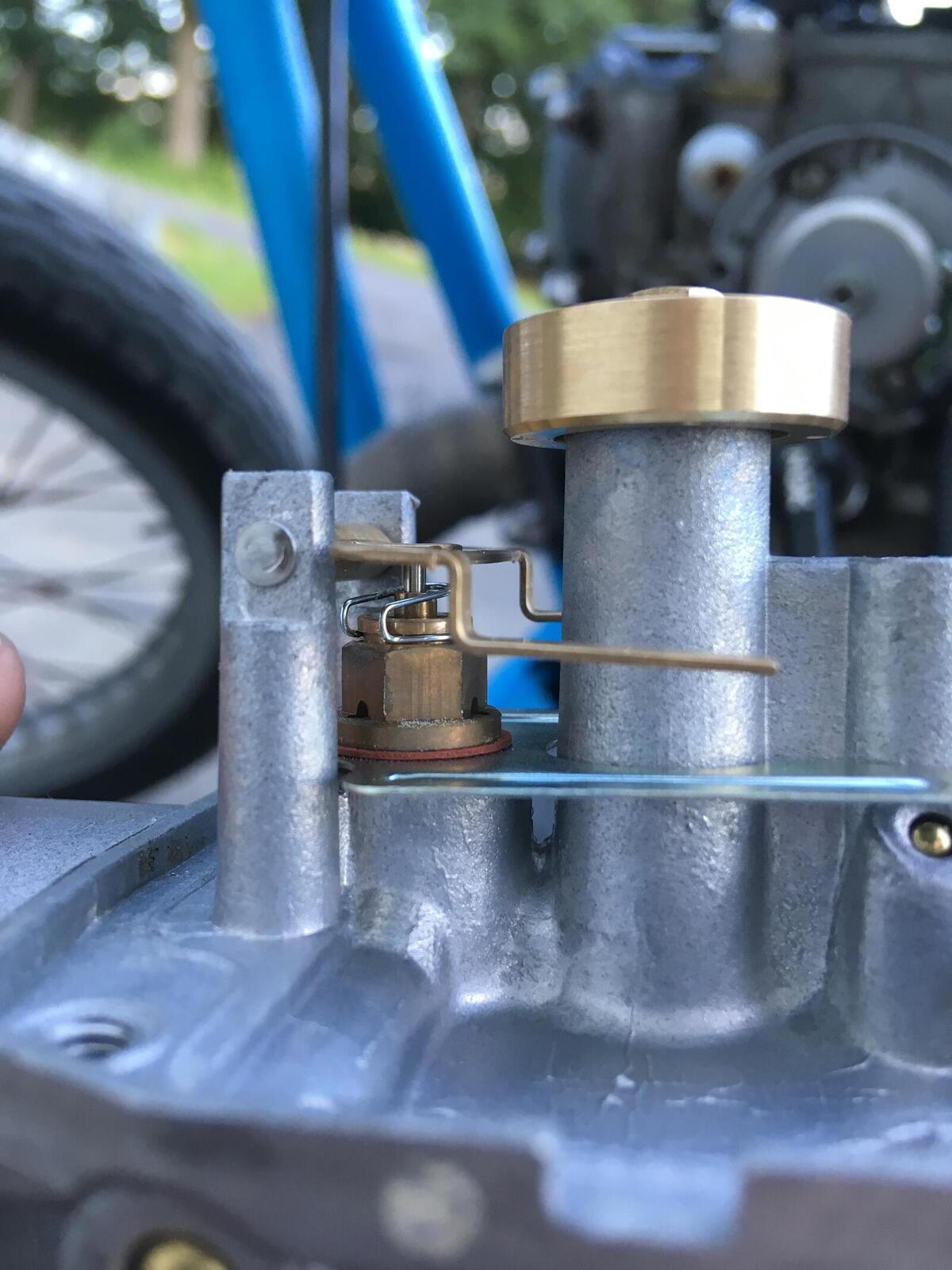

Was having a tough time getting it to run reliably so I figured I should check the float level since many say that really should be step one. Here's what I found

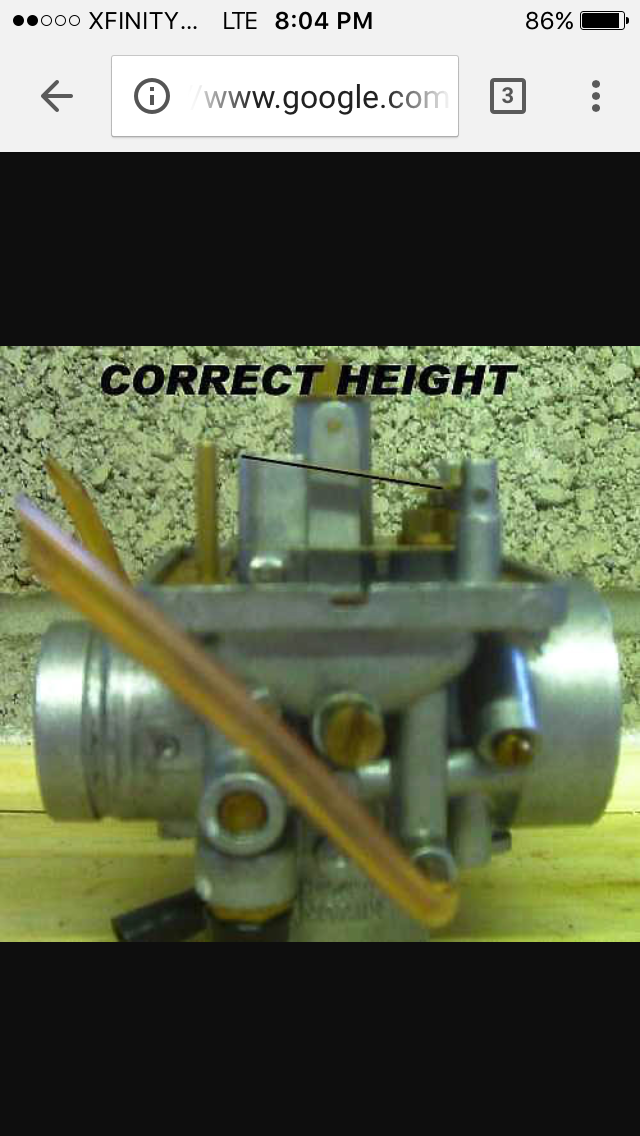

Well that's no good! Fresh from the factory, clip isn't even hooked onto the float arm so when the carb is in it's normal upright position, those brass arms would just hang down atop the floats. I'm not sure why exactly that's bad but I know it's not meant to sit that way. Also, the factory setting should be 17-19mm float height, as you can see it's nowhere close to that. I found these photos online of what it should look like, with a handy reference being that the brass arms should point to the upperleft corner of the pilot jet hole. See photo below

I was excited to get this adjusted, but unfortunately I hit another snag. The pin that holds the float arm on refuses to budge. I can't get it out at all. Tried tapping it gently, needlenose pliers, nothing. 100% stuck. Other side is a flat head like a nail, so it can only go out one way. Any tips for getting this loose?

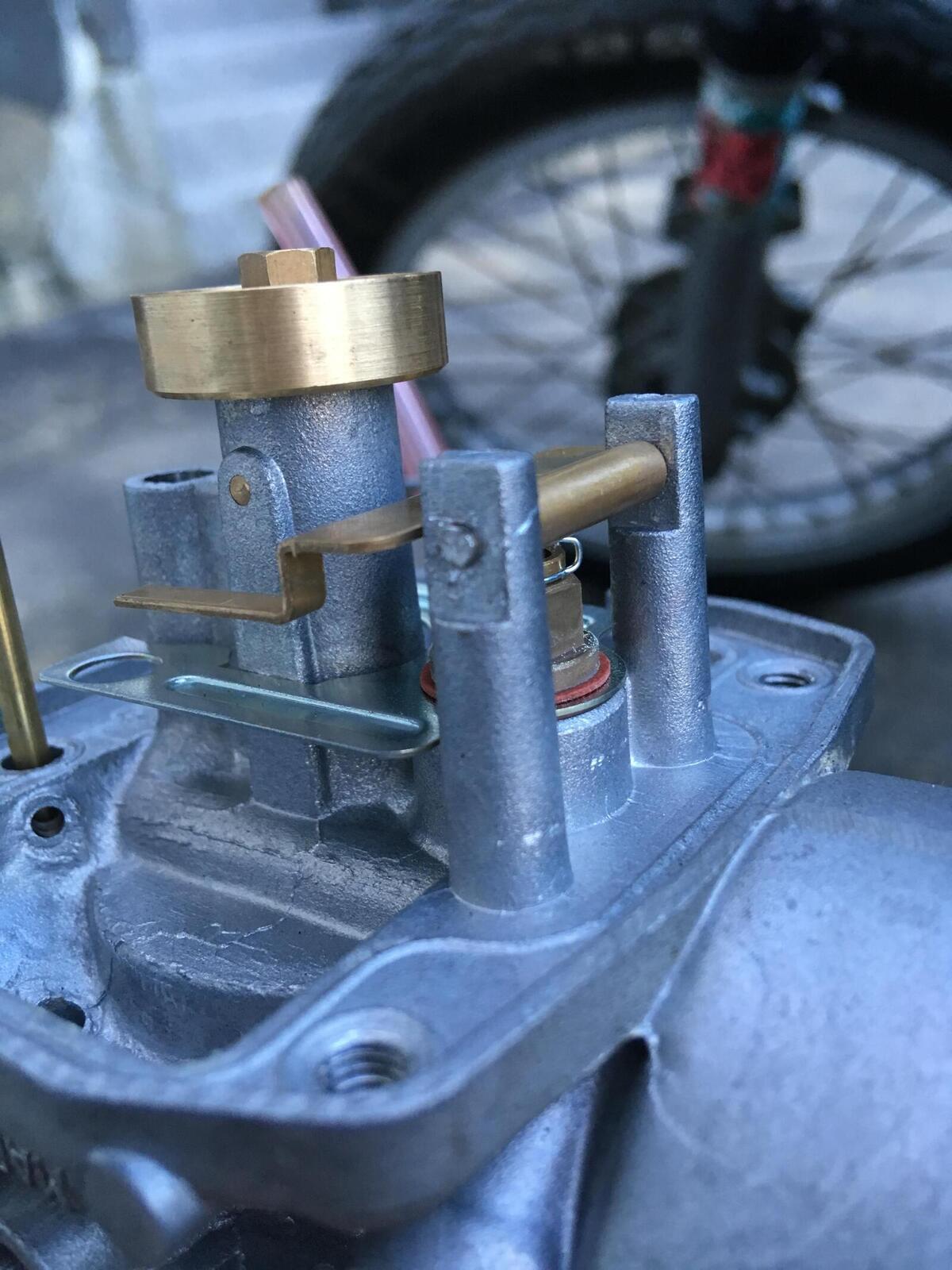

I did what I could to bend the tab to the correct position and did manage to get it pointing to that upperleft corner. However, getting the little clip around it was really a challenge. I think I got it on there decently, but I had to fuss with it a bit to ensure it didn't limit the travel of the float arm, would have been a lot easier if that damn pin would come out!

Overall, I got it back together and tried to start the bike again but an electrical issue seems to be throwing yet another wrench into the mix here. Hoping to test this thing soon to see if my float fix did the trick. I'm THIS close to throwing this whole carb and manifold in the trash and getting that TC Bros VM34 kit.

22.5 pilot

190 main

6f9 needle with circlip middle slot.

159, p-8 needle jet.

Mix screw out 3/4 turn from seat

Was having a tough time getting it to run reliably so I figured I should check the float level since many say that really should be step one. Here's what I found

Well that's no good! Fresh from the factory, clip isn't even hooked onto the float arm so when the carb is in it's normal upright position, those brass arms would just hang down atop the floats. I'm not sure why exactly that's bad but I know it's not meant to sit that way. Also, the factory setting should be 17-19mm float height, as you can see it's nowhere close to that. I found these photos online of what it should look like, with a handy reference being that the brass arms should point to the upperleft corner of the pilot jet hole. See photo below

I was excited to get this adjusted, but unfortunately I hit another snag. The pin that holds the float arm on refuses to budge. I can't get it out at all. Tried tapping it gently, needlenose pliers, nothing. 100% stuck. Other side is a flat head like a nail, so it can only go out one way. Any tips for getting this loose?

I did what I could to bend the tab to the correct position and did manage to get it pointing to that upperleft corner. However, getting the little clip around it was really a challenge. I think I got it on there decently, but I had to fuss with it a bit to ensure it didn't limit the travel of the float arm, would have been a lot easier if that damn pin would come out!

Overall, I got it back together and tried to start the bike again but an electrical issue seems to be throwing yet another wrench into the mix here. Hoping to test this thing soon to see if my float fix did the trick. I'm THIS close to throwing this whole carb and manifold in the trash and getting that TC Bros VM34 kit.