scrapmetal

XS650 Addict

Many of you know this: just do the work on a build that is necessary anyway, if your budget is exhausted, because I am at home without a job like many others during the Covid-19 Crisis and now have a lot of time.

The power bill, buying grocery's and daily needs (+ gas for the bike and money for a coffee somewhere) simply have priority!!

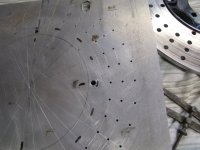

buy the way: the rotors are from the TX750, are they similar to the XS ? (I have none of the XS to compare diameter 298mm- 7mm thickness)

The power bill, buying grocery's and daily needs (+ gas for the bike and money for a coffee somewhere) simply have priority!!

buy the way: the rotors are from the TX750, are they similar to the XS ? (I have none of the XS to compare diameter 298mm- 7mm thickness)

It may have took a while but, they sure are straight!

It may have took a while but, they sure are straight!