Punkskalar

Hugh's HandBuilt

http://hughshandbuilt.blogspot.com/2011/03/failed-cranks-why-to-properly-build-and.html

A bad crank can be cause for problematic charging systems, bearing wear, cylinder issues, and even be the answer for all those mystery aluminum shavings that keep coming up in your oil.

Ok, let me start off by saying that I have heard several people say that welding the cranks is a waste of time unless it is in a full race engine, big bore, etc.. Well I've been tearing down engines now for a few years, and have come across this more times than I can remember. This crank is just ONE example, but I've seen them come apart at the centers, rod pins, both, etc...

See how this rod pin isn't near flush with the flywheel?

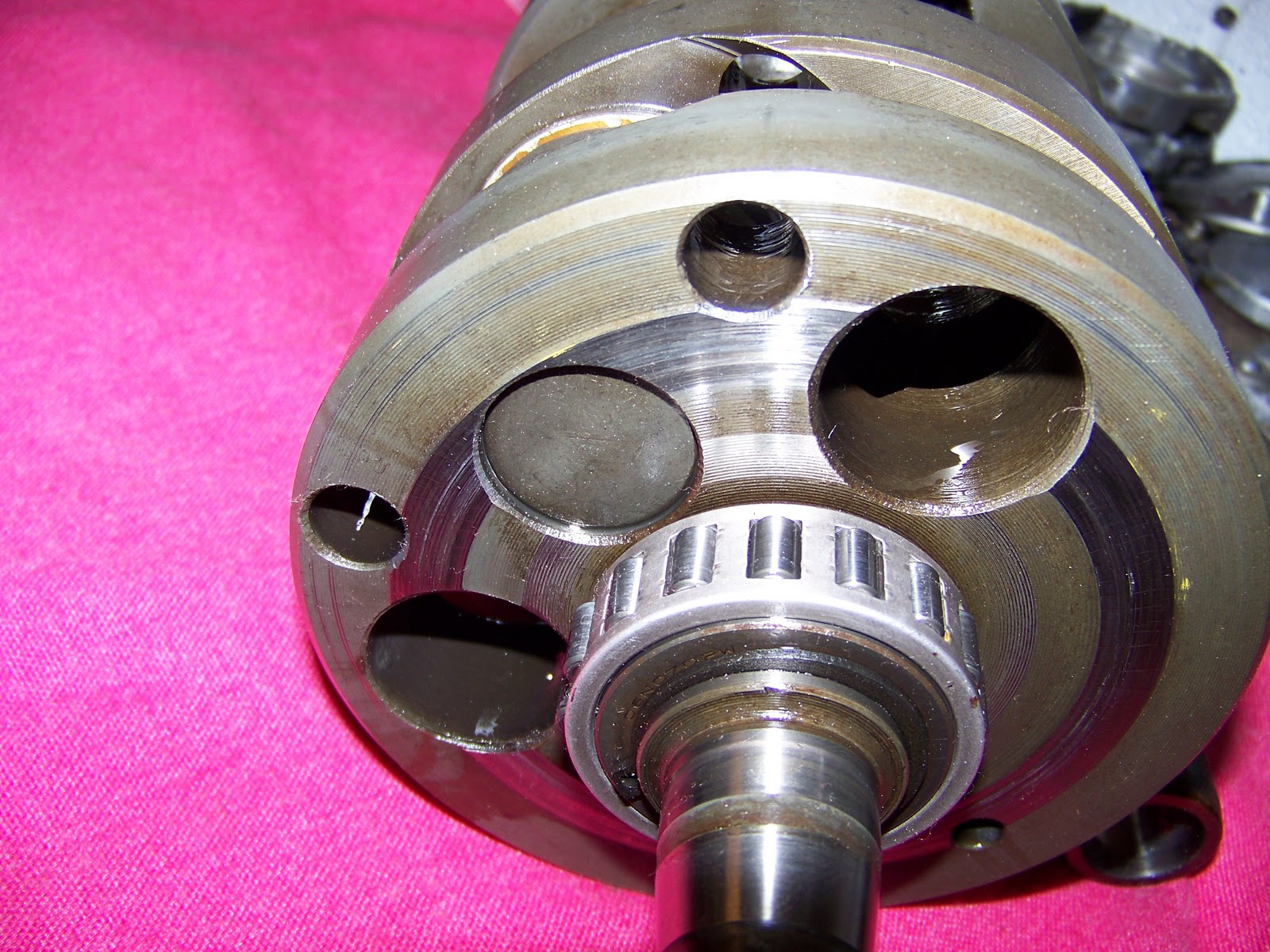

Another view to give you an idea of the depth of the pin.

See this scoring on the flywheel? This is from the flywheel crashing into the cases. Not good folks.

To much side to side play in the rod = Uneven and non centered forces on the piston as the rod moves back and forth on the pin. This will cause pinching and binding in the cylinders as the piston travels up and down. Probably not a good thing.

Having a charging issue you can't solve? Might be directly linked to a crank coming apart as the flywheel has pushed the charging rotor into the alternator housing, grounding out and being a complete pain in the you know what to diagnose. I've had several engines come in with charging issues, only to find out that the entire system has been toasted due to the flywheels separating.

FYI - This was a stock bottom end, with a 750 Big Bore kit. I've seen this problem on many stock engines, big bore kitted engines, and non-welded rephased cranks as well. If you are putting money into your engine, make sure the crank is done PROPERLY.

So what is a Properly built crank you ask:

Simply put, it must be built from the center out. All pressed joints must be TIG welded for proper penetration and minimal buildup of filler material (clearances on the rod bearings and crank bearings are TIGHT around some of the welds). All clearances must be in spec, and all flywheels must be checked for runout before final welding. Yes, it takes time to do, but anything worth doing, is worth doing right the first time.

A bad crank can be cause for problematic charging systems, bearing wear, cylinder issues, and even be the answer for all those mystery aluminum shavings that keep coming up in your oil.

Ok, let me start off by saying that I have heard several people say that welding the cranks is a waste of time unless it is in a full race engine, big bore, etc.. Well I've been tearing down engines now for a few years, and have come across this more times than I can remember. This crank is just ONE example, but I've seen them come apart at the centers, rod pins, both, etc...

See how this rod pin isn't near flush with the flywheel?

Another view to give you an idea of the depth of the pin.

See this scoring on the flywheel? This is from the flywheel crashing into the cases. Not good folks.

To much side to side play in the rod = Uneven and non centered forces on the piston as the rod moves back and forth on the pin. This will cause pinching and binding in the cylinders as the piston travels up and down. Probably not a good thing.

Having a charging issue you can't solve? Might be directly linked to a crank coming apart as the flywheel has pushed the charging rotor into the alternator housing, grounding out and being a complete pain in the you know what to diagnose. I've had several engines come in with charging issues, only to find out that the entire system has been toasted due to the flywheels separating.

FYI - This was a stock bottom end, with a 750 Big Bore kit. I've seen this problem on many stock engines, big bore kitted engines, and non-welded rephased cranks as well. If you are putting money into your engine, make sure the crank is done PROPERLY.

So what is a Properly built crank you ask:

Simply put, it must be built from the center out. All pressed joints must be TIG welded for proper penetration and minimal buildup of filler material (clearances on the rod bearings and crank bearings are TIGHT around some of the welds). All clearances must be in spec, and all flywheels must be checked for runout before final welding. Yes, it takes time to do, but anything worth doing, is worth doing right the first time.

Last edited: