Thought since I was in the process of this I should document. I see a lot of new builders popping up on here so thought this would be helpful to some. I'm by no means an expert, but there are some very crafty guys on here so I'm hoping by the end of this I'll have a rock solid wiring harness.

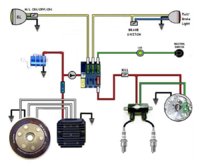

I will be using this diagram as my guide. Though it will have small changes in it.

What I've done so far is solder and shrink wrap the wires from my headlight and brake light. They are both aftermarket. The headlight is a one wire so I drilled a small hole in the bulb housing and attached a ground wire with a sheet metal screw and it's working fine so far. I've also figured out how to attach the rear brake light to the factory rear brake switch but we'll touch on that later.

Thus far both lights work as intended when off the bike and attached to a battery. But alas when on the bike I'm having trouble establishing a good ground for the headlight. So the fun begins, my intention was to ground the headlight on the coil mount hidden under my tank, but it's not working. I thought I had enough bare metal exposed on the frame to ground it but I'm doing something wrong. Hopefully daddyg or another more experienced can help sort this out so we can move on to the brake light. Here's a pic of what I'm trying to do for the ground.

Just to clarify I'm just using cheap solder less connections on this particular endeavor to establish I'm going in the right direction. It will be tidied up once I know it works.

I will be using this diagram as my guide. Though it will have small changes in it.

What I've done so far is solder and shrink wrap the wires from my headlight and brake light. They are both aftermarket. The headlight is a one wire so I drilled a small hole in the bulb housing and attached a ground wire with a sheet metal screw and it's working fine so far. I've also figured out how to attach the rear brake light to the factory rear brake switch but we'll touch on that later.

Thus far both lights work as intended when off the bike and attached to a battery. But alas when on the bike I'm having trouble establishing a good ground for the headlight. So the fun begins, my intention was to ground the headlight on the coil mount hidden under my tank, but it's not working. I thought I had enough bare metal exposed on the frame to ground it but I'm doing something wrong. Hopefully daddyg or another more experienced can help sort this out so we can move on to the brake light. Here's a pic of what I'm trying to do for the ground.

Just to clarify I'm just using cheap solder less connections on this particular endeavor to establish I'm going in the right direction. It will be tidied up once I know it works.