Beauty is in the eye of the beholder? Perhaps, but I believe that every XS650 owner sees beauty in even the ugliest of XS's. Even if it's not right in front of them. Well, I acquired a beautiful, ugly-duckling XS2.

Original plan was for me to chop and hard tail a later model XS. I live in Maryland though and this state seems to really like it titles. Or at least the need for one already in place. So all of the lower priced "Bill of Sale" only bikes were a no go. Then a clean, titled 1972 popped up. Decided it was the right time (and the right price) and pulled the trigger.

Boy it was ugly, but it ran, shifted and went. Only ran with the choke on, but didn't want to run it too much so it never really got up to temperature. It also stopped...mostly. Only went about 100 feet, and boy did it feel like a complete danger ride. Shifted back into neutral with ease. Turned it off, and pushed it to the place I was going to tear it apart at.

Since getting it, I discovered that the 1972 XS2 may not be the right bike to chop as it is somewhat classic in nature. Decided a restore job may be inline. Started tearing it down and discovered something bad, so I am back to the original plan. Hard tail the classic.

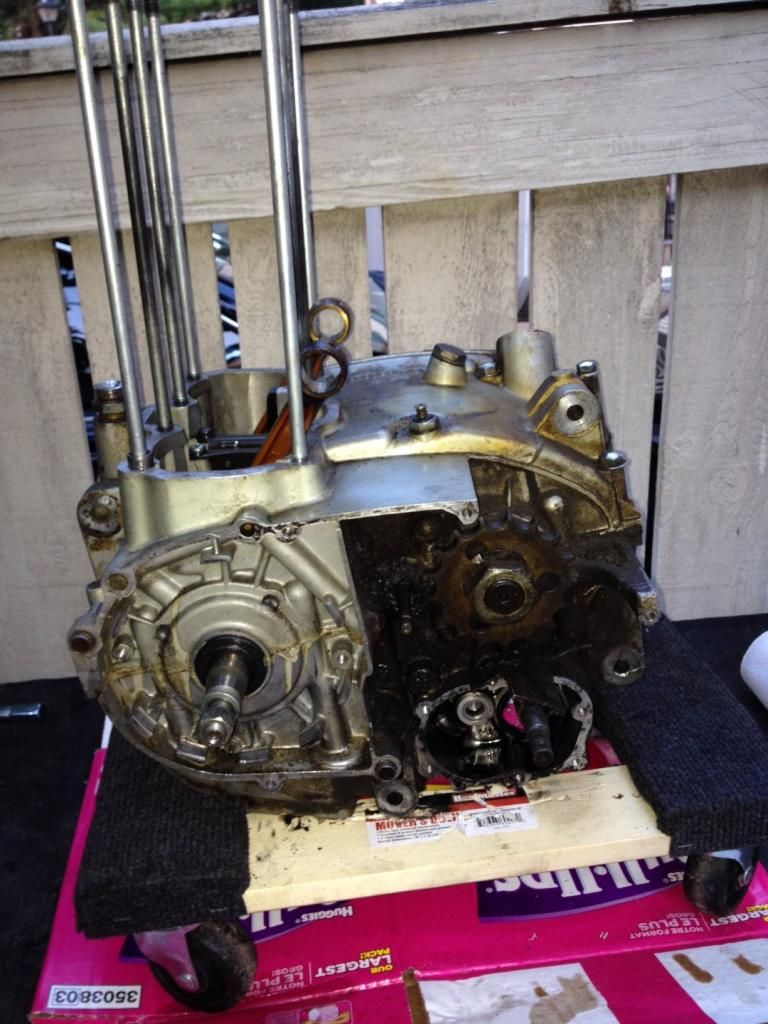

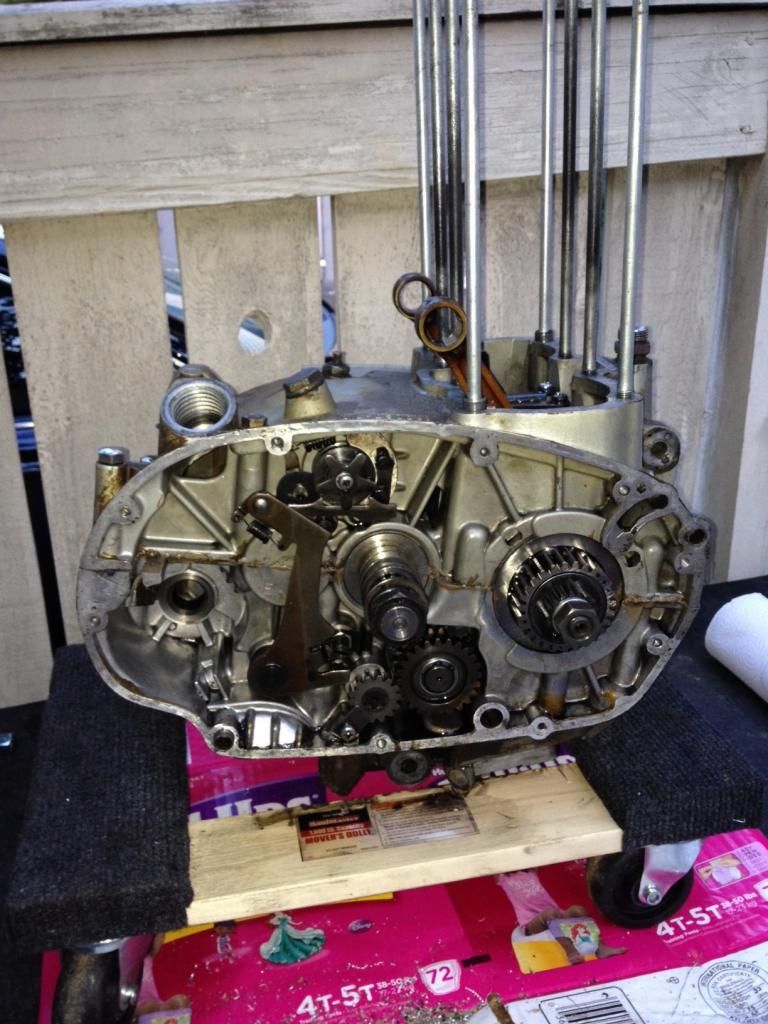

Some pictures.

The day I brought it home.

3 1/2 hours later (once I was able to get to it 2 weeks later that is)

And the engine as of a few days ago.

To be continued.

Original plan was for me to chop and hard tail a later model XS. I live in Maryland though and this state seems to really like it titles. Or at least the need for one already in place. So all of the lower priced "Bill of Sale" only bikes were a no go. Then a clean, titled 1972 popped up. Decided it was the right time (and the right price) and pulled the trigger.

Boy it was ugly, but it ran, shifted and went. Only ran with the choke on, but didn't want to run it too much so it never really got up to temperature. It also stopped...mostly. Only went about 100 feet, and boy did it feel like a complete danger ride. Shifted back into neutral with ease. Turned it off, and pushed it to the place I was going to tear it apart at.

Since getting it, I discovered that the 1972 XS2 may not be the right bike to chop as it is somewhat classic in nature. Decided a restore job may be inline. Started tearing it down and discovered something bad, so I am back to the original plan. Hard tail the classic.

Some pictures.

The day I brought it home.

3 1/2 hours later (once I was able to get to it 2 weeks later that is)

And the engine as of a few days ago.

To be continued.