XS650 Carburetor Metalurgy ...or... "What is this mystery potmetal"

I've seen this question occasionally, "What casting metal is my carb?".

This can be important to know, if considering aggressive cleaning agents, or fixable repairs.

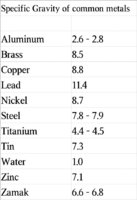

Without doing extensive chemical tests, it's possible to determine the likely metals in a Non-Destructive Test (NDT), by finding the metal's Specific Gravity.

40 miles north of here is the beginning of large areas of calcite, and mixed-in with all those calcite stones is the jewel of central Texas - Topaz. Topaz and calcite are virtually indistinguishable, near impossible to separate one from the other. However, Topaz has a slightly higher Specific Gravity compared to calcite. So, about a dozen years ago, I built a simple weighing system to help me sort and find precious stones.

The portable sealed field kit.

Opened up to reveal the precision digital mini weighing scale, specimen basket and water tub.

The specimen is placed in the basket, weight is recorded.

Then a lever is pulled, bringing the water tub up, submerging the specimen.

The specimen's submerged weight is recorded. Subtracting this weight from the specimen's weight gives the weight of the volume-displaced water.

Dividing the specimen weight by the displaced water weight gives the Specific Gravity.

Easy, huh?

I've seen this question occasionally, "What casting metal is my carb?".

This can be important to know, if considering aggressive cleaning agents, or fixable repairs.

Without doing extensive chemical tests, it's possible to determine the likely metals in a Non-Destructive Test (NDT), by finding the metal's Specific Gravity.

40 miles north of here is the beginning of large areas of calcite, and mixed-in with all those calcite stones is the jewel of central Texas - Topaz. Topaz and calcite are virtually indistinguishable, near impossible to separate one from the other. However, Topaz has a slightly higher Specific Gravity compared to calcite. So, about a dozen years ago, I built a simple weighing system to help me sort and find precious stones.

The portable sealed field kit.

Opened up to reveal the precision digital mini weighing scale, specimen basket and water tub.

The specimen is placed in the basket, weight is recorded.

Then a lever is pulled, bringing the water tub up, submerging the specimen.

The specimen's submerged weight is recorded. Subtracting this weight from the specimen's weight gives the weight of the volume-displaced water.

Dividing the specimen weight by the displaced water weight gives the Specific Gravity.

Easy, huh?