-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XS650 clutch

- Thread starter inxs

- Start date

Works a charm. With the impact driving the bit solidly into the head of the bolts they strip out much less.

Oh once you get them out, there is a mod to make them much better. Basically you drill them out so you can use an Allen head bolt. I use my drill press and set the bolts in a vice and drill from the head toward the threaded section. If carefully done you will drill right into the threaded section dead center.

You can grind the heads flat first if you want. Use, I think 35 mm long bolts. What ever size you use have the hub off the engine, thread the Allen bolts through the modified stock bolts, threads them into the hub. Look at the back of the hub, you don't want the Allen bolts sticking out. If any do grind them off. I did it with them threaded in, just ground them flush with the hub.

Too long and they will grind a groove in the basket. Not fun to clean out the aluminum bits.

Leo

Oh once you get them out, there is a mod to make them much better. Basically you drill them out so you can use an Allen head bolt. I use my drill press and set the bolts in a vice and drill from the head toward the threaded section. If carefully done you will drill right into the threaded section dead center.

You can grind the heads flat first if you want. Use, I think 35 mm long bolts. What ever size you use have the hub off the engine, thread the Allen bolts through the modified stock bolts, threads them into the hub. Look at the back of the hub, you don't want the Allen bolts sticking out. If any do grind them off. I did it with them threaded in, just ground them flush with the hub.

Too long and they will grind a groove in the basket. Not fun to clean out the aluminum bits.

Leo

40mm is the proper screw length to use for this mod. 45s are too long and cause problems like Leo mentioned. With the domed top ground flat on the original screw, the 40s are just perfect .....

Last edited:

hard_y_rd

XS650 Guru

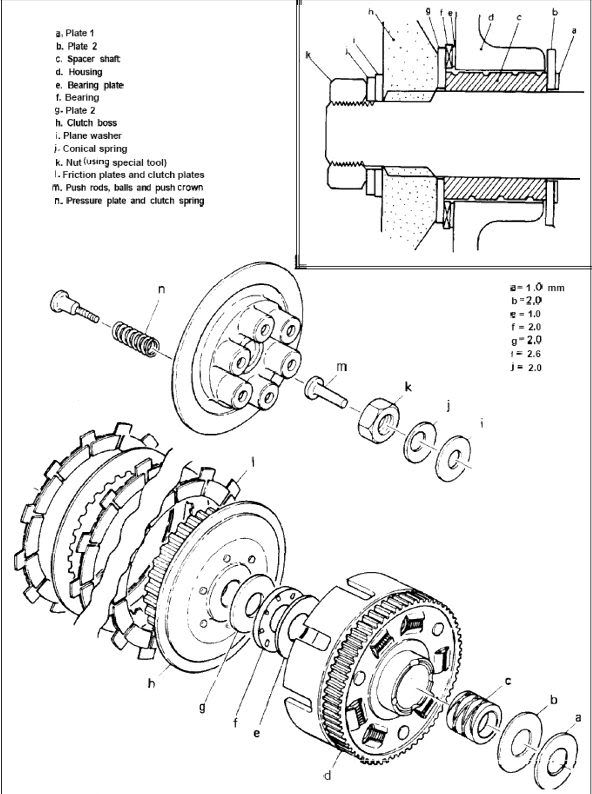

2. Assembly

First thing to remember here is that, in their wisdom, Yamaha left a Thrust Washer off the diagrams. Between hub and boss they show a washer (25-50-2) and a thrust bearing – missing is the washer (31-51-0.5) between needle bearing and hub..(e)..

Next point to remember is 2-2-2...each step requires 2 washers..see above diagram

Install:

2 washers/shaft-to-hub-bush (hub) thrust bearing/2 washers (boss) 2 washers/nut

*Crankcase

*Bush

*Washer..25.2-36-1.0

*Washer...25-50-2

*Hub

*Washer...35-51-0.5 **this is usually missing from diagrams, therefore gets left out**

*Thrust Bearing

*Washer...25-50-2

*Boss

*Washer...plain

*Washer...Spring Bellville/lock washer

*Nut

*Push Rod End

This sequence ignores plate packing and Mikesxs recommendation that you pack thrust bearing direct against hub, then covered by the 2 washers.

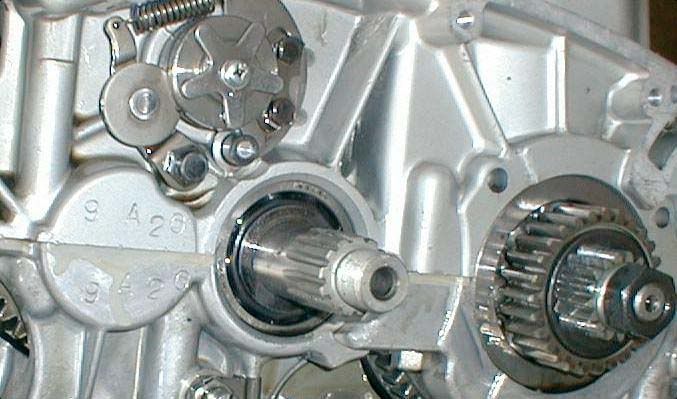

Also be aware that when the internal 2 piece push rod was introduced many parts books and manuals showed, in pictures, installation with the turned down end pointed towards the clutch hub, instead, this reduced end locates into the worm gear pushing against the ball bearing crimped into it...you will know its installed wrong when you either cant close the case or have no pressure at the clutch handle

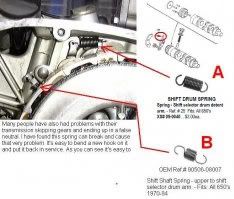

So, before starting check the 2 shift mechanism springs

Ensure:

-the spacer is ok

-you have the 2 washers

-there are no rubbing marks

-the primary drive dampening springs are intact

-the hub basket dogs are not worn, cracked, bent, broken..bent/broken, replace-rilled, if not too bad lightly file-reduces friction plate catching, if bad, replace

...install...

-thin washer

-bearing...mikesxs has a good replacement

-thick washer

-boss, check that splines are not worn

-washer

-spring/lock washer

-nut...18mm...55-59 ft/lb...80 N.m...8.1 kg/m

...install...

-make sure the ball bearing is in the shaft...oil

-push rod(s - bearing)

...install clutch pack...

-pressure plate...if yours has splines make sure they register

-springs...all same size and within specs

-screws...tighten with impact driver - 5-7 ft/lb...9.0-9.5 N.m...0.8-1.0 kg/m...use #3 bit so you dont damage the phillips head

CLUTCH PACKS

The different packs, 6-7-6 plates, are interchangeable as a unit. As the early, thicker plates (3.5mm) are not available anymore, Mikesxs suggest removing the rubber rings and installing an extra steel and friction plate pair in the early clutch packs.

The 7 plate pack is known to increase risk of primary gear dampening spring failure.

My personal suggestion is to change in a later model 6 plate pack - straight swap.

When installing

- soak new friction plates in oil-overnight if possible...Note that your bike needs 20W-40, which is available at truck stops and auto stores...eg Shell Rotella, Pennzoil without the additives found in modern automobile motor oils. Wrong oil = clutch problems...big time!!!

- check steel plates for warping-lay on plate glass, if you can rock it or slide a 0.008"(0.2mm) feeler guage under, replace

- buff the sharp edges smooth...as these are stamped-out, the top edges are rounded by the die, the bottom edges are left sharp...buff these smooth with a wire wheel

- scuff the surfaces lightly with emery paper to remove glazing - wash

- check friction plates for wear...new-3.0mm...min-2.7mmm (earlier, 3.5mm new/3.1mm min)

- lightly bevel the edges of the friction plate tabs with a file...this helps prevent them catching on the basket fingers

NOTE...when installing the later sprung 6 plate pack, be aware that there are 2 different steel plates...the plate that belongs to the anti loading pack that goes into the boss first is thicker than the others, 1.6mm as opposed to 1.4mm - dont mix them up

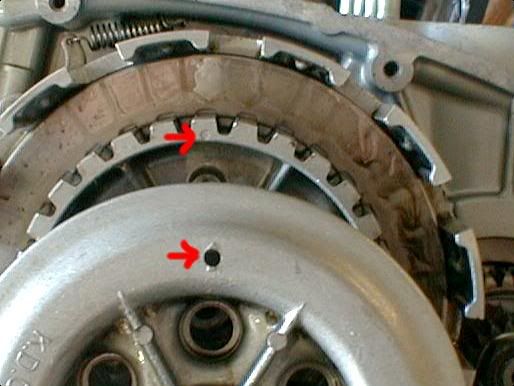

Alignment

- if not aligned properly the cluth will be noisy and not work properly

...this hole must align with the mark on the boss

...like this

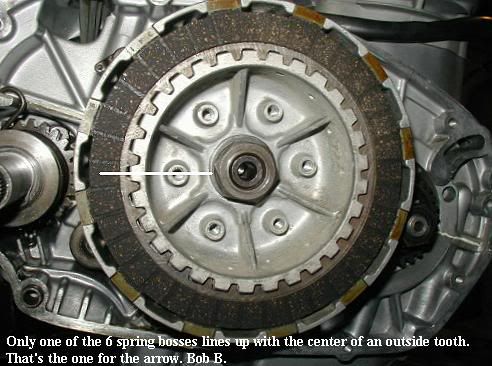

...when there is no mark or hole then align as below...only 1 screw boss lines up with a tooth centre-this is where the pressure plate must align...mark the tooth

I have an early clutch with no holes or markings. It says to line up the pressure plate to this point. Which point on the pressure plate is it referring to?

The early pressure plates had no internal splines to engage the boss (hub) splines. They can be installed in any orientation...

hard_y_rd

XS650 Guru

Good to know, TooMany. One less thing to worry about...

theGorton

Gort

awesome post 5 twins saved me and made me aware of why my last 2 builds have had rough clutches particularly my last build 6 years ago. looking at it al now its makes sense everything actually finishes flush, great post thanks heaps

alwaysmonday

XS650 Addict

I understand that new fiber disc need soaked in oil before use. Does typical motorcycle spec oil work for this? How long should they be soaked?

Jon

Jon

Yes, use motorcycle spec oil, the same you'll be putting in the bike. Pour a little in a pan, submerge a plate, then put it in the clutch. In the old days, cork composition plates enjoyed a little soak time, but nowadays you can put it right in. It'll get a little soak time while you're reassembling the engine...

Focusinprogress

XS650 Addict

So, I know this is an old thread but I need to ask some silly questions.

to make a long story short, I acquired a 1981 xs650....disassembled and the motor partially apart because one of the pistons developed a hole. I then separately acquired a pre-TCI engine to swap in. the new engine didn't come with any of the covers, so I swapped mine on as well as the rotor and stator/tci pickup. Now, I get the bike together and it fires right up runs well etc....

I adjust the clutch to have just before no play in the lever, and start the bike. grab clutch lever and attempt to shift into first, it doesn't go in and I can hear a whirring/almost-grinding sound.

I can put it into second gear and I went around the block. so, while still running I pulled the little cap and went to play with the clutch adjustment. what I discovered, is I can wind the adjuster in enough to allow me to pull in the clutch and get into first gear...but when I go to let out of the lever I am not fully disengaged by the time I've let go....and the lever is snug with not even a teeny bit of play in the cable. I came across this thread wondering if I was missing a push rod or ball, but I now suspect I either have a wrong cable or the wrong worm-gear (or possibly have it on the wrong worm groove??)

I haven't had the RH cover off for any reason, but I know I have the multi-rod style, where under the LH cover I have a ball in the worm gear, then a 3.5-4" or so rod where the end facing the cover is slightly smaller diameter.

in summary, I think I have a late 70's motor (that was originally a points-ignition motor) that I've swapped into the 1981 bike, using the 1981 LH cover/clutch actuator(wormgear) and 1981 cable.

wondering if there was a difference in the worm gear or cable that could be causing my issue. if the rods are different I can take the ones from the 1981 motor, the bottom end is still in-tact.

thanks in advance for reading all of that, esp if you offer any help/advice.

to make a long story short, I acquired a 1981 xs650....disassembled and the motor partially apart because one of the pistons developed a hole. I then separately acquired a pre-TCI engine to swap in. the new engine didn't come with any of the covers, so I swapped mine on as well as the rotor and stator/tci pickup. Now, I get the bike together and it fires right up runs well etc....

I adjust the clutch to have just before no play in the lever, and start the bike. grab clutch lever and attempt to shift into first, it doesn't go in and I can hear a whirring/almost-grinding sound.

I can put it into second gear and I went around the block. so, while still running I pulled the little cap and went to play with the clutch adjustment. what I discovered, is I can wind the adjuster in enough to allow me to pull in the clutch and get into first gear...but when I go to let out of the lever I am not fully disengaged by the time I've let go....and the lever is snug with not even a teeny bit of play in the cable. I came across this thread wondering if I was missing a push rod or ball, but I now suspect I either have a wrong cable or the wrong worm-gear (or possibly have it on the wrong worm groove??)

I haven't had the RH cover off for any reason, but I know I have the multi-rod style, where under the LH cover I have a ball in the worm gear, then a 3.5-4" or so rod where the end facing the cover is slightly smaller diameter.

in summary, I think I have a late 70's motor (that was originally a points-ignition motor) that I've swapped into the 1981 bike, using the 1981 LH cover/clutch actuator(wormgear) and 1981 cable.

wondering if there was a difference in the worm gear or cable that could be causing my issue. if the rods are different I can take the ones from the 1981 motor, the bottom end is still in-tact.

thanks in advance for reading all of that, esp if you offer any help/advice.

Focusinprogress, these threads won't directly answer your question, there's too many variables that need to be checked. But, they will give you insight into the workings of the clutch actuation mechanisms.

Warning, long threads, will destroy your weekend (and maybe your vision).

These are all parts of the XS650 clutch actuator experiments:

Clutch worm actuator experiment and tidbits

Clutch worm mod testing

Clutch pushrod experiment and tidbits

Clutch cable experiment and tidbits

Clutch worm rotation gauge

Clutch worm depth dialgauge-post90

Clutch worm depth dialgauge-post91

Clutch worm depth dialgauge-post92

Warning, long threads, will destroy your weekend (and maybe your vision).

These are all parts of the XS650 clutch actuator experiments:

Clutch worm actuator experiment and tidbits

Clutch worm mod testing

Clutch pushrod experiment and tidbits

Clutch cable experiment and tidbits

Clutch worm rotation gauge

Clutch worm depth dialgauge-post90

Clutch worm depth dialgauge-post91

Clutch worm depth dialgauge-post92

hein weijers

XS650 Special (5E6) 1982

Maybe it is wise to adjust the clutch in the right way first.

- First loosen the the clutch cable at the handlebar until there is plenty of play.

- Loosen the screw at the side cover.

- Turn in the screw until you feel it push the worm actuator.

- Turn the screw 1/4 turn back and lock it.

- Adjust the cable play at the handlebar.

Hein

- First loosen the the clutch cable at the handlebar until there is plenty of play.

- Loosen the screw at the side cover.

- Turn in the screw until you feel it push the worm actuator.

- Turn the screw 1/4 turn back and lock it.

- Adjust the cable play at the handlebar.

Hein

Focusinprogress

XS650 Addict

Maybe it is wise to adjust the clutch in the right way first.

- First loosen the the clutch cable at the handlebar until there is plenty of play.

- Loosen the screw at the side cover.

- Turn in the screw until you feel it push the worm actuator.

- Turn the screw 1/4 turn back and lock it.

- Adjust the cable play at the handlebar.

Hein

that was how I had it at the beginning, when it wouldn't go into 1st, hence then seeing how far I had to wind it in to get it into first, which then left me with not enough travel at the lever.

My post was meant to ask if there are a difference in the wormgear between the late 70's and the 1980 bike that I put the earlier motor in....specifically, does the gear have a different amount of travel? if so, that explains everything.

Focusinprogress

XS650 Addict

Focusinprogress, these threads won't directly answer your question, there's too many variables that need to be checked. But, they will give you insight into the workings of the clutch actuation mechanisms.

Warning, long threads, will destroy your weekend (and maybe your vision).

These are all parts of the XS650 clutch actuator experiments:

Clutch worm actuator experiment and tidbits

Clutch worm mod testing

Clutch pushrod experiment and tidbits

Clutch cable experiment and tidbits

Clutch worm rotation gauge

Clutch worm depth dialgauge-post90

Clutch worm depth dialgauge-post91

Clutch worm depth dialgauge-post92

Thank you so much for this reply, it was EXTREMELY helpful. I think the parts I have may just be worn and therefore causing my issue. I am going to try the motion pro cable and drill a new hole in the actuator arm in an attempt to gain more travel in the worm gear per lever pull and see if this gets me into first gear properly. I think I have a mismatched arm for the two piece clutch rod that's in the motor I'm using.

No, there is no difference in the worm part of the worm gear, only in where the cable attaches. See post #3 on page one. I think there's something wrong with your clutch assembly in the "new" motor you swapped in. You'll probably need to disassemble and inspect it. Some of the plates may be trashed. I've run across a couple clutches in parts motors that were just a mess. Some of the friction plates were worn completely out, all the friction material gone.

Between this one and the clutch in your original motor, you should be able to assemble one good one, or swap the whole '81 clutch in. Or you can swap the '81 inner basket and plates into the "new" motor's outer basket.

Between this one and the clutch in your original motor, you should be able to assemble one good one, or swap the whole '81 clutch in. Or you can swap the '81 inner basket and plates into the "new" motor's outer basket.

Focusinprogress

XS650 Addict

No, there is no difference in the worm part of the worm gear, only in where the cable attaches. See post #3 on page one. I think there's something wrong with your clutch assembly in the "new" motor you swapped in. You'll probably need to disassemble and inspect it. Some of the plates may be trashed. I've run across a couple clutches in parts motors that were just a mess. Some of the friction plates were worn completely out, all the friction material gone.

Between this one and the clutch in your original motor, you should be able to assemble one good one, or swap the whole '81 clutch in. Or you can swap the '81 inner basket and plates into the "new" motor's outer basket.

I'll likely do that. the gasket on this earlier motor is leaking on the top side somehow, which leads me to think it's been off without a new gasket...so I ordered a new gasket already....I'll inspect the clutch itself once I have it open, and do like you say combining the parts from this and the '81 motor to make the best clutch I can from the lot.

Your '81 should have the later 6 plate inner hub with the bottom damper plate. Your earlier motor most likely has the 7 plate clutch. The 6 plate engages smoother and puts less stress on the little damper springs on the back of the main hub. I think it's the better choice for normal use.

Nils

XS650 Member

Hello everyone,

I'm having an issue with my 1978 SX650E. The clutch will not engage at all. I recently did have the LH case off to do a PM system install on my bike and during that I did pull the pushrod out of it spot to inspect it. I did check the trouble shooting tree provided earlier in this thread and following it I figured maybe the worm gear was messed up. So I removed it, disassembled it, cleaned it and inspected if for all its parts. Everything was there with no real wear so I reassembled it with new grease and re-installed it. I adjusted everything up again and retested, no good. I have been looking thought my Haynes manual and I notice its shows a two piece push rode so now I'm wondering if I'm missing a rod? missing a ball ? Did the ball inbetween the two push rods fall into the trans somewhere?

Any help or in site into this would be great.

Thanks.

I'm having an issue with my 1978 SX650E. The clutch will not engage at all. I recently did have the LH case off to do a PM system install on my bike and during that I did pull the pushrod out of it spot to inspect it. I did check the trouble shooting tree provided earlier in this thread and following it I figured maybe the worm gear was messed up. So I removed it, disassembled it, cleaned it and inspected if for all its parts. Everything was there with no real wear so I reassembled it with new grease and re-installed it. I adjusted everything up again and retested, no good. I have been looking thought my Haynes manual and I notice its shows a two piece push rode so now I'm wondering if I'm missing a rod? missing a ball ? Did the ball inbetween the two push rods fall into the trans somewhere?

Any help or in site into this would be great.

Thanks.

hein weijers

XS650 Special (5E6) 1982

Hello Nils,

When your XS has a 2-piece rod, than there are 3 balls: 1 in the worm gear (this one can fall out sometimes), 1 between the 2 rods and 1 at the clutch side.

It is not possible for a ball to fall into the gearbox.

Dit you replace the worm in the right position?

Regards, Hein

When your XS has a 2-piece rod, than there are 3 balls: 1 in the worm gear (this one can fall out sometimes), 1 between the 2 rods and 1 at the clutch side.

It is not possible for a ball to fall into the gearbox.

Dit you replace the worm in the right position?

Regards, Hein