Those animations are AWESOME in 3D!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yamaha XS650 Valve Train Geometry

- Thread starter TwoManyXS1Bs

- Start date

Haha, gggGary, any excuse to nibble popcorn...

The mystery machine is a pivoting/rotating fixture to hold 8mm diameter XS650 parts, for grinding the tips.

The fixture is like a small lathe, with a clamping finger-collet to hold the workpiece.

In the past, I'd rework valve adjuster tips offhand on the lathe, using a dremel and radius gauges.

This time around, I wanted something more precise for this larger radius.

The first item to be reworked is a badly worn/chipped valve adjuster screw.

The mystery machine is a pivoting/rotating fixture to hold 8mm diameter XS650 parts, for grinding the tips.

The fixture is like a small lathe, with a clamping finger-collet to hold the workpiece.

In the past, I'd rework valve adjuster tips offhand on the lathe, using a dremel and radius gauges.

This time around, I wanted something more precise for this larger radius.

The first item to be reworked is a badly worn/chipped valve adjuster screw.

The baseplate for the fixture has a protruding pivot pin.

The pivot pin is set at 19mm (3/4") from the face of the abrasive disc.

Then the baseplate is clamped to the disc sander's table.

The pivot pin is set at 19mm (3/4") from the face of the abrasive disc.

Then the baseplate is clamped to the disc sander's table.

The fixture is fitted over the pivot pin, and the fixture's slide is adjusted to just before the workpiece contacts the abrasive disc. The slide's leadscrew is simply a long #10-32 screw, which makes the feedrate about 0.001" per 12° of knob rotation.

And here's the boring 1 minute video of the thing in action:

View of the valve adjuster tip after grinding:

Yeah, it's a bit rough. So, we'll polish it.

The adjuster screw is held in an 8x1.0mm threaded wand.

The adjuster screw is held in an 8x1.0mm threaded wand.

After a few seconds at the polishing wheel:

(The reflection is the overhead shoplight)

(The reflection is the overhead shoplight)

goodgollyjosh

XS650 Addict

That is awesome!!

The grinding fixture can also hold valves with 8mm stems. Here, a junk valve is chucked up, ready for resurfacing. Note the cracked/crazed tip surface.

Grinding fixture locked into 90° position. Valve tip slowly fed into grinder.

View of ground valve tip.

Only about 0.003"-0.004" removed, saving the stellite surface.

After a few seconds at the polishing wheel, the valve can be returned to service...

Here's a resurfacing project on valve and clutch screw adjusters:

http://www.xs650.com/forum/showthread.php?t=41639

Grinding fixture locked into 90° position. Valve tip slowly fed into grinder.

View of ground valve tip.

Only about 0.003"-0.004" removed, saving the stellite surface.

After a few seconds at the polishing wheel, the valve can be returned to service...

Here's a resurfacing project on valve and clutch screw adjusters:

http://www.xs650.com/forum/showthread.php?t=41639

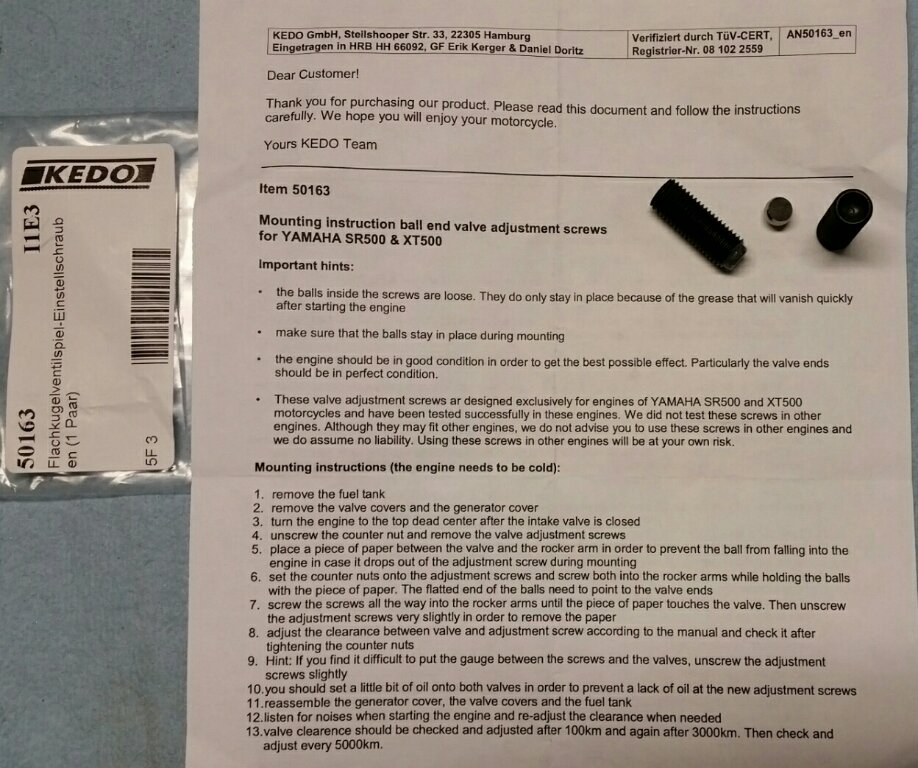

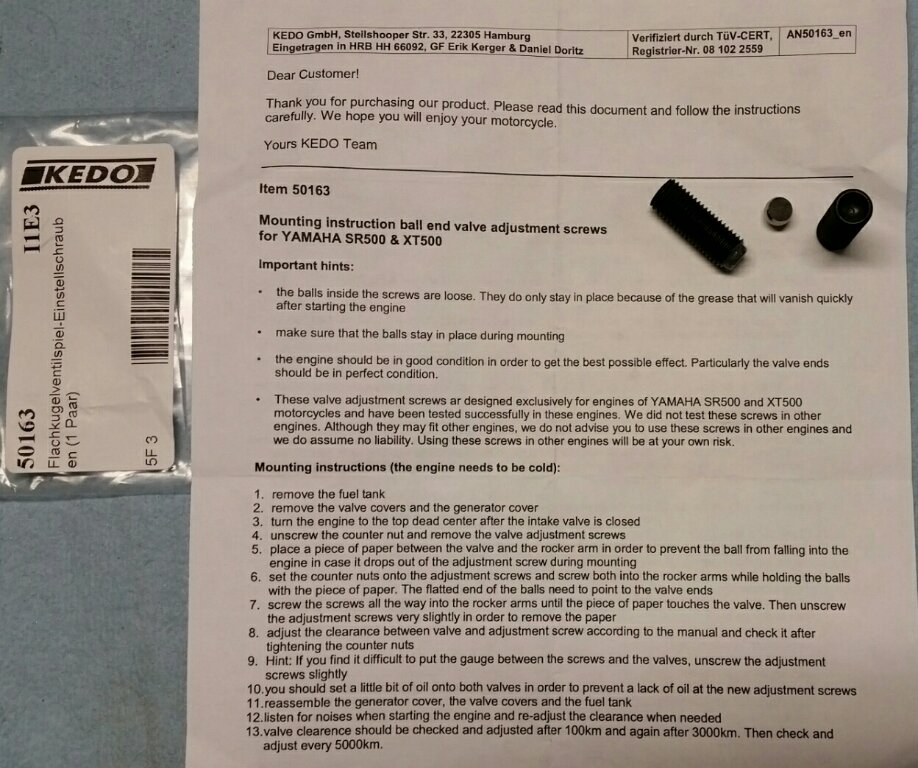

Finally received a set of Kedo flat-ball valve adjuster screws, so a little thread refresh.

Found in album: http://www.xs650.com/media/albums/2635/

Here's the supplied instruction sheet.

Note that the intended use is strictly for the Yamaha 500cc singles.

Found in album: http://www.xs650.com/media/albums/2635/

Here's the supplied instruction sheet.

Note that the intended use is strictly for the Yamaha 500cc singles.

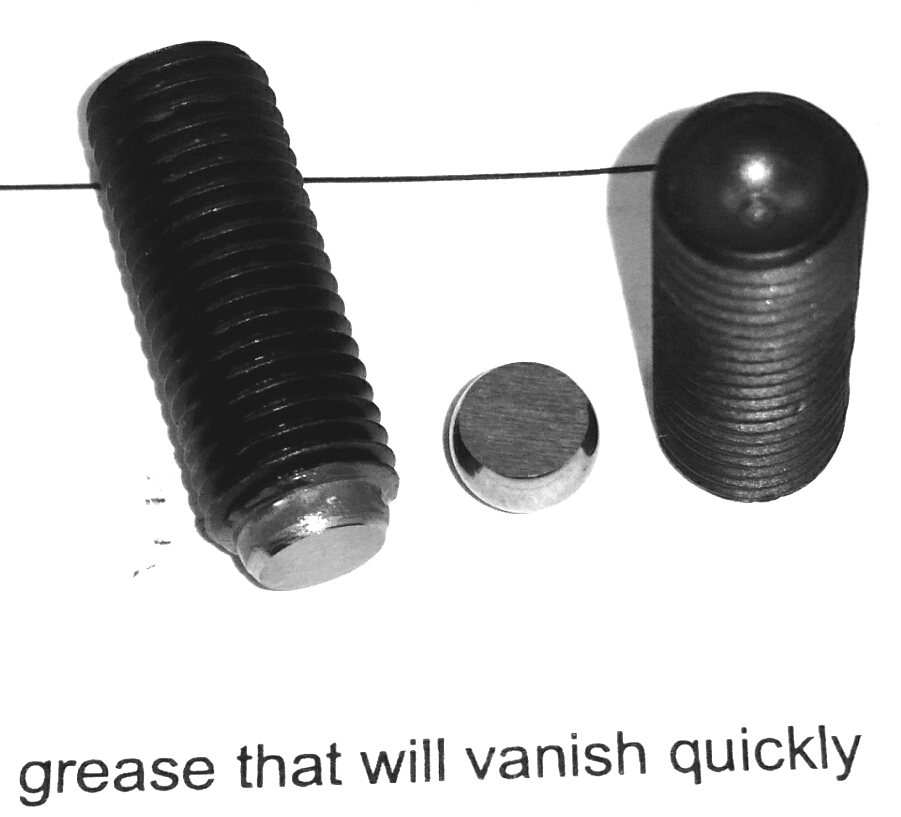

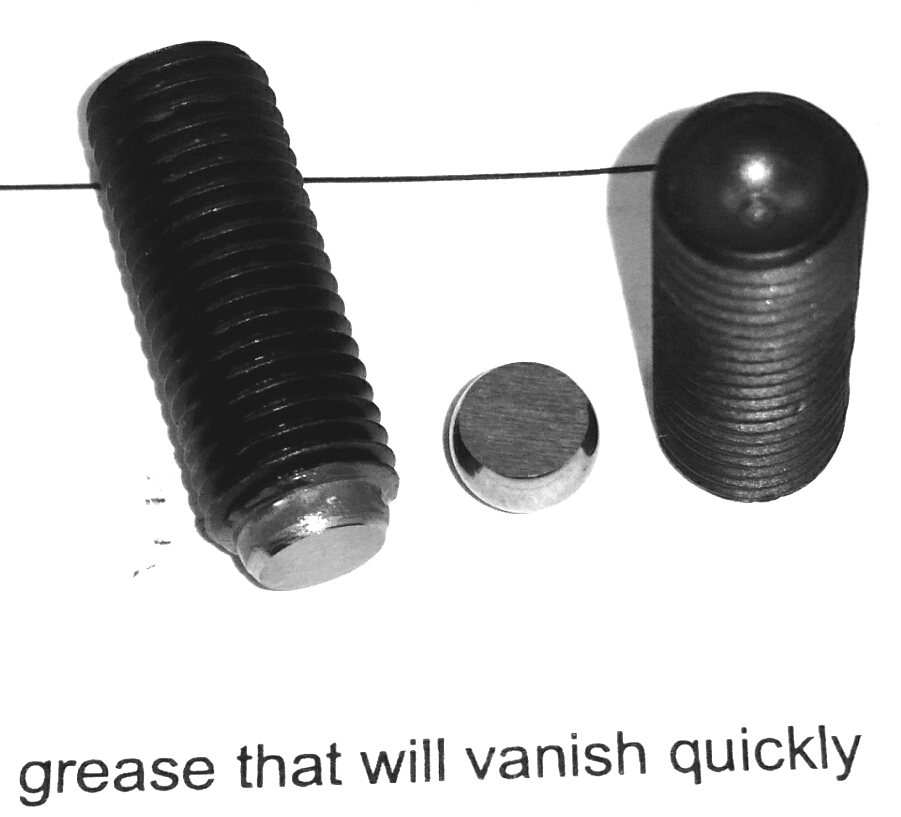

I originally thought that the flat-ball was retained by a crimped edge, similar to the elephants foot retention, but the Kedo flat-ball is retained in the socket by adhesion to the supplied moly grease.

The ball can be rotated in its socket so that a tiny screwdriver can get behind it to pop it out.

The ball is highly polished, and the adjuster screw's pocket is very well machined, smooth, and black oxide plated. There's also a tiny oil reservoir dimple at the base of the ball's pocket

About 1.5mm is ground off the 6mm ball to make the flat face. This means that the ball's rotation center is only 1.5mm above the valve stem end. This should reveal a different 'scrub' distance.

The Kedo flat-ball adjuster alongside a stock XS650 adjuster for comparison.

The Kedo adjuster has a hex key pocket, so it doesn't need to be as long, and will be lighter.

Did an impromptu lean angle measurement, and found that the Kedo adjuster can be leaned over as much as 30° from vertical. The lean angles of our XS650's adjusters are in the range of +/- 6°, so no concern here about adjuster angles...

The ball can be rotated in its socket so that a tiny screwdriver can get behind it to pop it out.

The ball is highly polished, and the adjuster screw's pocket is very well machined, smooth, and black oxide plated. There's also a tiny oil reservoir dimple at the base of the ball's pocket

About 1.5mm is ground off the 6mm ball to make the flat face. This means that the ball's rotation center is only 1.5mm above the valve stem end. This should reveal a different 'scrub' distance.

The Kedo flat-ball adjuster alongside a stock XS650 adjuster for comparison.

The Kedo adjuster has a hex key pocket, so it doesn't need to be as long, and will be lighter.

Did an impromptu lean angle measurement, and found that the Kedo adjuster can be leaned over as much as 30° from vertical. The lean angles of our XS650's adjusters are in the range of +/- 6°, so no concern here about adjuster angles...

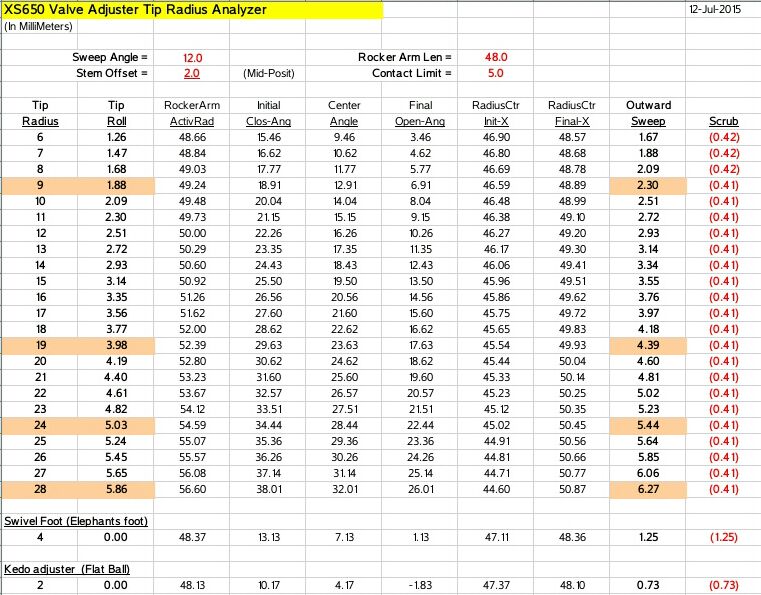

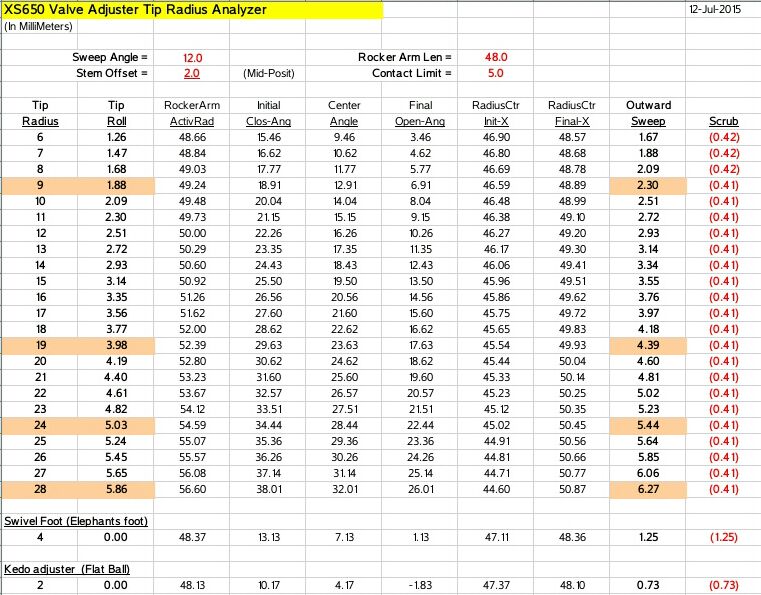

Updated the "Sweep and Scrub" spreadsheet to include the Kedo adjusters (at bottom).

The scrub value shown is only 0.73mm (0.029"). But, at the last part of valve travel, the adjuster tip actually goes a little past center, and reverses direction by a tiny amount. So, the 'total' scrub distance will be a little more. Will calculate that later...

The scrub value shown is only 0.73mm (0.029"). But, at the last part of valve travel, the adjuster tip actually goes a little past center, and reverses direction by a tiny amount. So, the 'total' scrub distance will be a little more. Will calculate that later...

glennpm

Another Old Biker Nut!

Great stuff once again TooMany!

hoffman900

XS650 Addict

TwoManyXS1Bs, shoot me a PM with your email. I want to talk more about this with you regarding the SR/TT 500s. Thanks!

Hey 2M ---Wow lots of tappet tech info here. I have noticed a machine co on Ebay [smw70ss] in Portland,OR offering a valve tappet re-grinding service, 4 tappets $15, seems pretty cheap. Take a look and let us know if this is any good or just BS. Thanks tm

Hoffman900, you've been "conversationed".

Timbeck! Yes, I saw the eBay listing [smw70ss] some time ago. Don't know anything about what they're doing with tappets, radiusing, hardening, ...etc. They're no strangers to XS650s and machine shop work, so no BS there...

Timbeck! Yes, I saw the eBay listing [smw70ss] some time ago. Don't know anything about what they're doing with tappets, radiusing, hardening, ...etc. They're no strangers to XS650s and machine shop work, so no BS there...

Similar threads

- Replies

- 69

- Views

- 17K