Great DIY work on those brackets!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It's past time to start XS2 Resurrection

- Thread starter GLJ

- Start date

I wasn't really too loud. It had a drone to it. People didn't like riding behind me. At a steady speed it would wear on me. Actually had a lot of comments from people that were not riding behind me that it sound very good going down the road.You know you're gettin' old when the bikes too loud.

I use the same acrylic car paint sealant on every part I cleanRims look excellent. now make 'em run strait. I use the same acrylic car paint sealant on every part I clean, chrome, aluminum..or, paint after I get em where they need to be. It stops any further oxidation and has a smooth feel finish...poly-grip bonds

What do you use ??

Nice job on the Commando installation Greg! They look like they were made for your bike!

Nice job on the Commando installation Greg! They look like they were made for your bike!

I use the same acrylic car paint sealant on every part I clean

What do you use ??

I was thinking the high temp Duplicolor clear....Too permanent. Have been using for years 4 Star Products pain on my nice bicycles for years (and my car):https://www.fourstarproducts.com/ulpagupl4oz.html...I'm going with that once I finish screwing with aluminum n chrome parts. I lasts and if you get everything dirty...just clean off and I spray the polycharged acrylic wax on/wipe off. I used to take detailing classes from one of the owners of 4 star Products. The private label for retail 'off the shelf' names you'd know....world wide.

Time for a few changes.

Rode the old girl a few times last week. Decided I was tired of the way it sounded. I liked the 2 into 1 I had on it but the sound wears on you after a couple hundred smiles. I got a set of Commandos a few weeks ago for a future bike. Since I had them I decided to use them. Also had a somewhat decent set of head pipes from a parts bike. Might as well put them to good use.

Did a little searching but didn't find anything on putting Commandos on a early bike. I'm sure it's been done hundreds of times. Decided how I wanted to do it and got started.

Made some hanger parts. After a lot of measuring and test fitting got them done.

View attachment 187254

View attachment 187256

Hangers mounted. I know it would be stiffer if I added a third piece of flat to triangulate the bracket. It seems plenty stiff. I made the hanger out of what I could get locally.

View attachment 187257

Spacer block installed. I know some of are wondering how I'm going to mount the passenger pegs. Simple as of right now I'm not. I really don't like riding 2 up. If my girlfriend wants to go for a ride I've got the BMr. If I ever decide to mount pegs I'll make new spacers with a longer stud.

View attachment 187258

Reason I didn't use a steel plate is the vertical piece had to have a bit of a twist in it to mate up with the spacer.

View attachment 187262

Assembled

View attachment 187259

View attachment 187260

Hope I conclude my bike in that together a mode...those pipes look good...nice job.

View attachment 187261

Next up a little fork modification.

I knew I made a mistake taking the plastic off my foam seat cushion. It was perfectly wrapped and would keep the water (freak rain storm??) out. For slipping the cover on over the foam, I saw at a fabric shop a roll of 'batting' I can cut a piece off the roll at the store of to tape/ stitch to the foam to help it slide the cover and fill in any wrinkles. I'll have to add that plastic back.

Are you using it for the side covers or just the wheels etc. that don't get hot from engine heatI was thinking the high temp Duplicolor clear....Too permanent. Have been using for years 4 Star Products pain on my nice bicycles for years (and my car):https://www.fourstarproducts.com/ulpagupl4oz.html...I'm going with that once I finish screwing with aluminum n chrome parts. I lasts and if you get everything dirty...just clean off and I spray the polycharged acrylic wax on/wipe off. I used to take detailing classes from one of the owners of 4 star Products. The private label for retail 'off the shelf' names you'd know....world wide.

Finished up a few things on the old girl. I'll start at the rear. Put a new tire on. Old one still had some smiles left on it but taking a trip early next month and didn't think it would make it. I had a 120/90x18 Conti Go on it. I liked it but decided to try a little smaller size. It ran pretty close to the chain guard. Went with a 110/90 Conti Go. Surprised at how much smaller it looks. Plenty of guard clearance. At the same I polished up the brake plate better. Since it had to be stripped down for that on reassembly I slipped in a set of new Versah brake shoes. Old ones had plenty of life left but wanted try a different brand.

When I changed to dual exhaust it created a problem with the center stand. I couldn't use it because because I had a muffler in the way. Before with no muffler I could reach the centerstand foot with my foot and bring it down to the ground. With my shortened stand all I needed to do was hold it against the ground and keep it from sliding backwards. So I added a tang and added a longer rubber bumper to keep the stand from banging into the muffler. Works nicely. And I think it looks pretty good. It may look spindly but with the shortened stand I don't need to put any more pressure on it than it takes to keep the stand from sliding backwards.

On to the front end.

Not a real good pic. The caliper is one I had rebuilt and painted with new pucks. The forks have been changed out to a different set. They may look like run of the mill XS2 forks but the only XS2 parts used are the top cap bolt and lower legs. They are a hybrid.

I've only got 250 or smiles on the changes, so far I'm very pleased. I like the smaller rear tire. The bike is more willing to lean in curves. Plus the front end doesn't come off the ground as easily because the rear breaks loose sooner.

Breaks are still bedding in, seems like they should be OK.

Breaks are still bedding in, seems like they should be OK.

I'm very happy with the front end changes. Rebuilt caliper/new pads works as expected. I used VHT High Temp Engine Enamel on them. Was concerned that brake fluid might cause a problem after bleeding them. I knew there was no way I would not get fluid on them. I was right but cleaned it off and the paint still looks fine. The fork changes I'm more than happy with. They worked and made the forks a lot less harsh over bumps. Nowhere close to modern standards but much better. The mod also allows me to try more improvements in the future. Not going to go into details here. Will be making a new thread on them soon. Will update this post with a link to it when I do.

When I changed to dual exhaust it created a problem with the center stand. I couldn't use it because because I had a muffler in the way. Before with no muffler I could reach the centerstand foot with my foot and bring it down to the ground. With my shortened stand all I needed to do was hold it against the ground and keep it from sliding backwards. So I added a tang and added a longer rubber bumper to keep the stand from banging into the muffler. Works nicely. And I think it looks pretty good. It may look spindly but with the shortened stand I don't need to put any more pressure on it than it takes to keep the stand from sliding backwards.

On to the front end.

Not a real good pic. The caliper is one I had rebuilt and painted with new pucks. The forks have been changed out to a different set. They may look like run of the mill XS2 forks but the only XS2 parts used are the top cap bolt and lower legs. They are a hybrid.

I've only got 250 or smiles on the changes, so far I'm very pleased. I like the smaller rear tire. The bike is more willing to lean in curves. Plus the front end doesn't come off the ground as easily because the rear breaks loose sooner.

Breaks are still bedding in, seems like they should be OK.

Breaks are still bedding in, seems like they should be OK.I'm very happy with the front end changes. Rebuilt caliper/new pads works as expected. I used VHT High Temp Engine Enamel on them. Was concerned that brake fluid might cause a problem after bleeding them. I knew there was no way I would not get fluid on them. I was right but cleaned it off and the paint still looks fine. The fork changes I'm more than happy with. They worked and made the forks a lot less harsh over bumps. Nowhere close to modern standards but much better. The mod also allows me to try more improvements in the future. Not going to go into details here. Will be making a new thread on them soon. Will update this post with a link to it when I do.

Yes, I'm a big fan of the 110 rear. I like it so much better than a fat 120 and it's all the tire you need.

Interesting centerstand bumper. All I ever do is stick some heater hose on the tang, simple but effective, lol .....

Interesting centerstand bumper. All I ever do is stick some heater hose on the tang, simple but effective, lol .....

It works. I thought about your hose mod,didn't like the look when stand was down. The old girl has a vain streak in her.Interesting centerstand bumper.

@fredintoon might recognize what it is normally used for.

Nice looking work there Greg! Careful, you keep shining the old girl up and they’ll accuse you of being OCD like me!

As you may have read in another thread while getting to the bottom of a compression problem I found out the small ends of my rods are worn out. Since in order to fix that the crank either needs to be rebuilt or replaced. Only one thing to put a 750 kit in it. I happened to have a 75 motor with less than 12,000 miles on it. It's donating its crank and trans towards the project. Engine is apart, some cleanup and ready to go back together.

You've got quite a project ahead of you!I found out the small ends of my rods are worn out.

Hope it goes well.

Such a frustration to find the small ends worn out. I've got a spare engine which I tore down a couple years ago and all I found wrong with it was seemingly serious small end rod wear. It's been sitting in the shop ever since, awaiting a practical solution.

Hey Greg! I’m trying to get my head around the scope of your project. Is it your plan to install the crank and tranny from the ‘75 into your XS2 cases? Add the 750 kit for the jugs and pistons, and then are you also going to take the cam from the ‘75 and use that, or are you thinking about an aftermarket cam? Helluva project! I can’t wait to see how this goes, I hope you post updates as you go along!

YesIs it your plan to install the crank and tranny from the ‘75 into your XS2 cases? Add the 750 kit for the jugs and pistons

I have not decided on a cam yet.

Really not much different than what I did 2 years ago when I had the top case welded. Instead of putting the old parts back in I'm using different parts.

Little update.

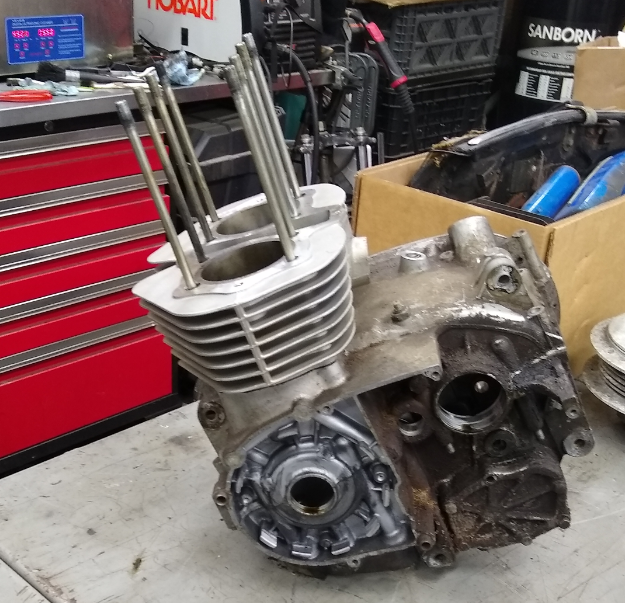

Crank and trans plus drum and forks in. Cases back together.

Next up get the BBK cylinders ready to go on.

Crank and trans plus drum and forks in. Cases back together.

Next up get the BBK cylinders ready to go on.

Very nice buddy! Any surprises lurking in there?

Little more progress.

The BBK I got had the 10mm holes in the cylinder where the studs pass through. Figured it was time to enlarge them. A few weeks ago I got some drill bits from Amazon. 10.5,11, 11.5 and 12mm. 2 each for around $45. Not the best bits in the world but figured they would be good enough.

Used my cheap drill press, piece of wood and my hands. I'm sure there are better ways but this is what I have. Thought it would work ok because I was only going .5mm at a time in aluminum. It did. If you do this at home and you do it freehand make sure your belts for the press are a little on the loose side. If you crowd the bit it will bite.

Test fit on a set of empty cases.

It's unfortunate that the blocks were not machined correctly. Considering the savings that I got when I bought it. I have no complaints. It only took a hour and a half to drill them. Plus I have 8 drill bits left over.I honestly think if you had a way to hold the block down on a bench they could be drilled out with a hand drill.

Next see if a buddy on mine who's a retired toolmaker will stop by and do some measuring for me. I'm sure the piston a bore job will be OK. Just curious how uniform the sizing of the pistons and bores are.

The BBK I got had the 10mm holes in the cylinder where the studs pass through. Figured it was time to enlarge them. A few weeks ago I got some drill bits from Amazon. 10.5,11, 11.5 and 12mm. 2 each for around $45. Not the best bits in the world but figured they would be good enough.

Used my cheap drill press, piece of wood and my hands. I'm sure there are better ways but this is what I have. Thought it would work ok because I was only going .5mm at a time in aluminum. It did. If you do this at home and you do it freehand make sure your belts for the press are a little on the loose side. If you crowd the bit it will bite.

Test fit on a set of empty cases.

It's unfortunate that the blocks were not machined correctly. Considering the savings that I got when I bought it. I have no complaints. It only took a hour and a half to drill them. Plus I have 8 drill bits left over.I honestly think if you had a way to hold the block down on a bench they could be drilled out with a hand drill.

Next see if a buddy on mine who's a retired toolmaker will stop by and do some measuring for me. I'm sure the piston a bore job will be OK. Just curious how uniform the sizing of the pistons and bores are.

It's great that you managed but a single reamer in each size would have done and would have been long enough you could have flipped the cylinder over onto the head gasket side which would have been more stable on your small drill press table.