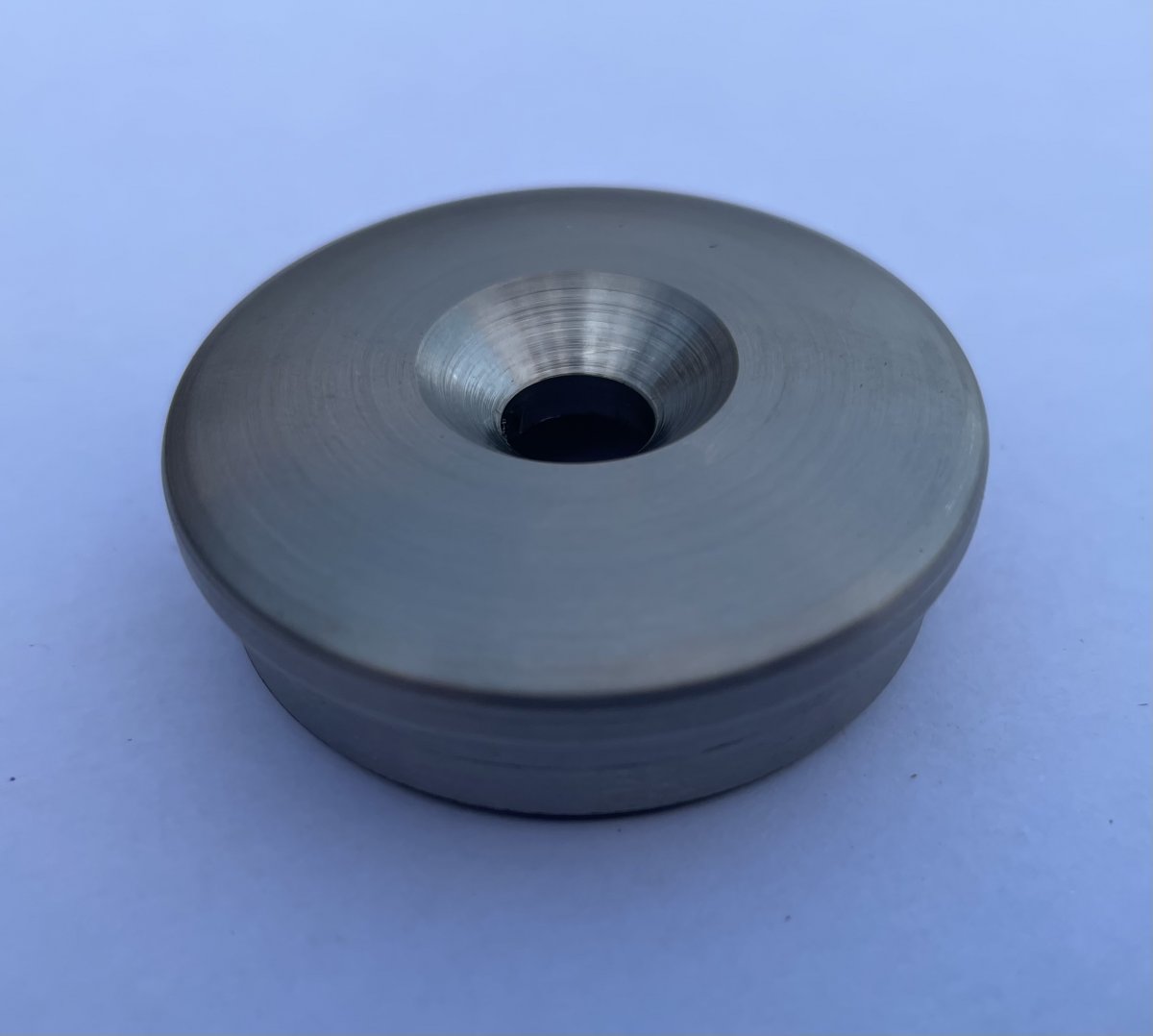

I like the look of the machined piece with the bolt.The ‘MK 2’ version is secured using a capping piece that is the exact size and shape of the factory plug. Visually the only differences are that it’s a machined aluminium piece (you could always sand the machining marks & polish) and there’s the head of an M8 countersunk bolt in the centre.

Daniel.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mr Riggs Hydraulic Clutch Conversion

- Thread starter Bewarethemoon

- Start date

I like the look of the machined piece with the bolt.

Me too @bosco659

Just wait until you see the actual version tomorrow!

ShaggyMech

Socal Mechanic.

Brilliant! love the design, can't wait to get it and put it through its paces. What size master cylinder do you recommend?

Brilliant! love the design, can't wait to get it and put it through its paces. What size master cylinder do you recommend?

I’m super excited to finish work and get over to Des’s (that’s my machinist), I feel after 12 months of him making stuff for me we’ve become friends and it seems strange to keep referring to him as ‘my machinist’, from now on he will be known by his actual name.

I’m using the clutch lever off a FZR-750, it’s the same lever as these..https://www.dimecitycycles.com/7-8-...tch-master-cylinder-aluminum-14mm-piston.html

I just tracked down what Yamaha models used them and then sourced one second hand off eBay so I didn’t have to spend the $150 they demand new.

I designed the slave cylinder to be used in conjunction with this lever but I’m sure there’s room for deviation, I don’t think I’d recommend going for a smaller piston in the master cylinder than 12mm though?

Daniel.

ShaggyMech

Socal Mechanic.

Perfect. 14-16mm is about standard for most applications.

Slippery

XS650 Member

There are lots of ready made l/h handle bar master cylinder levers available from as little as $35 new in silver or black finish with built in reservoirs eg https://www.banggood.com/search/hyd...1134-0-0-0-0-44-0-price-0-0_p-1.html?from=nav

There are lots of ready made l/h handle bar master cylinder levers available from as little as $35 new in silver or black finish with built in reservoirs eg https://www.banggood.com/search/hyd...1134-0-0-0-0-44-0-price-0-0_p-1.html?from=nav

They look okay, I’m just quite picky and wanted a clutch lever that matches my brake lever.

The Nissin clutch lever assembly from a YZF-750 matches the early model R6 brake lever assembly perfectly.

Paired with these Pazzo levers it should be a nice setup...

Daniel.

Yes thanks

Hope your not superstitious because you’re down for #13

Daniel.

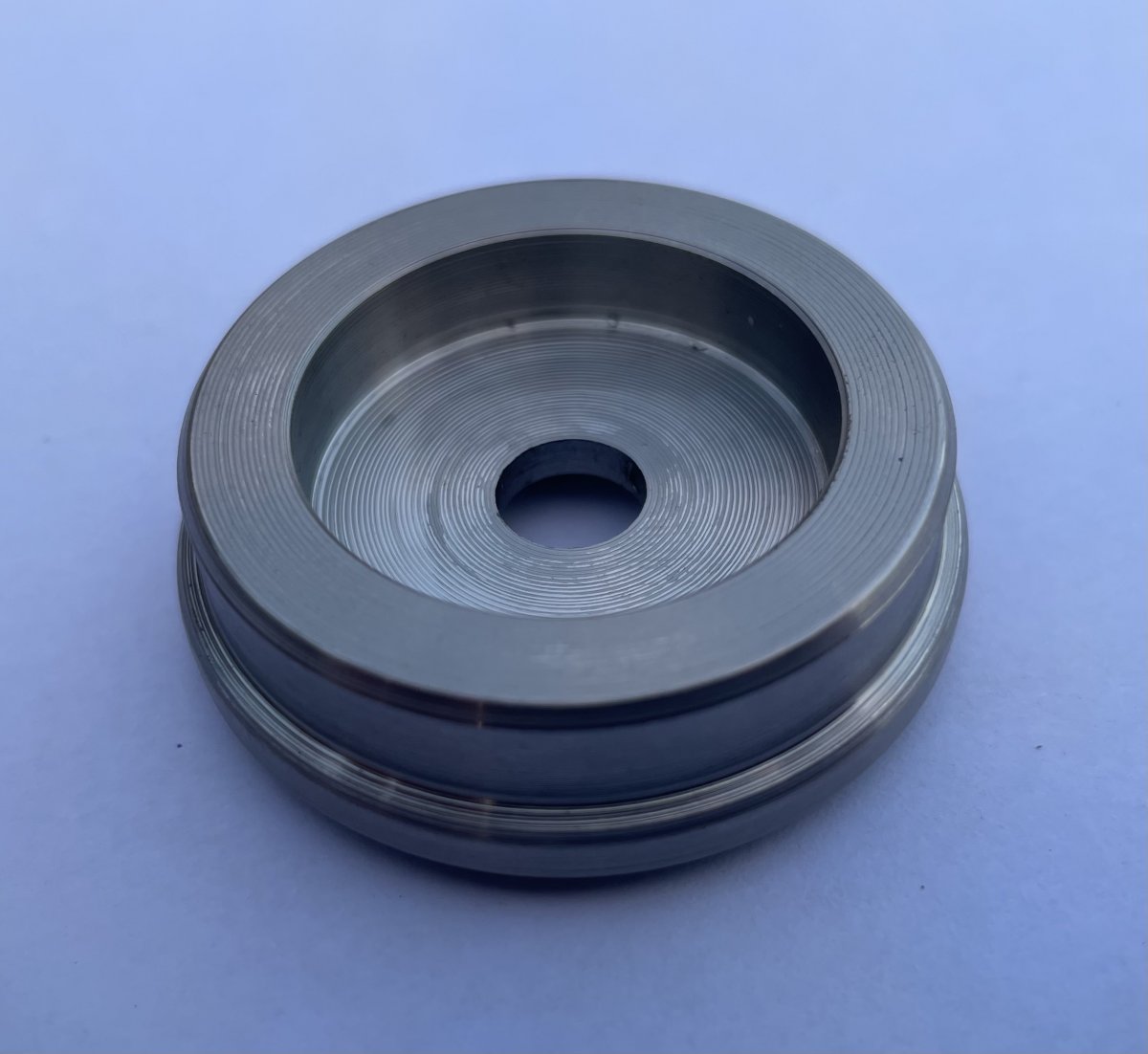

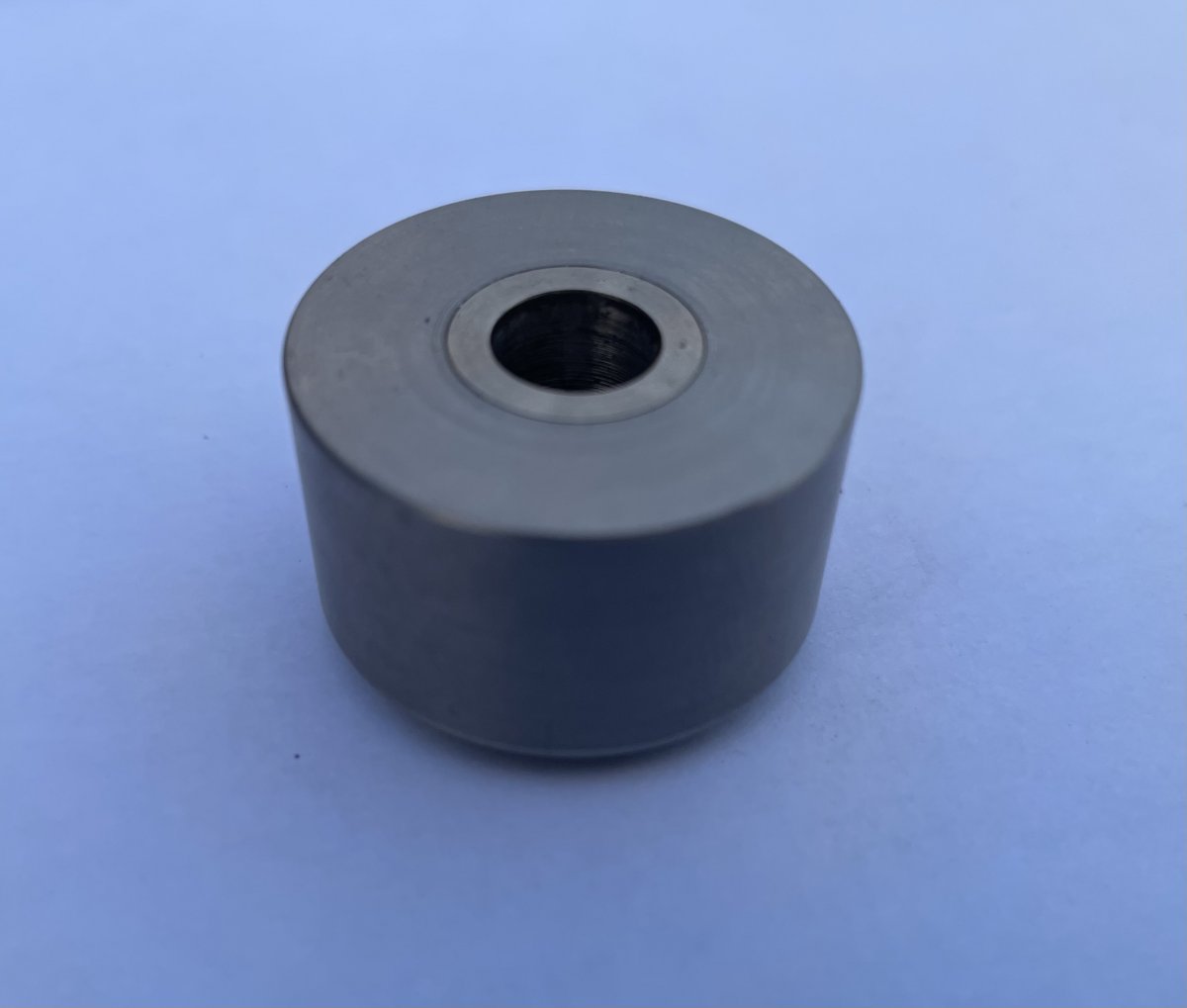

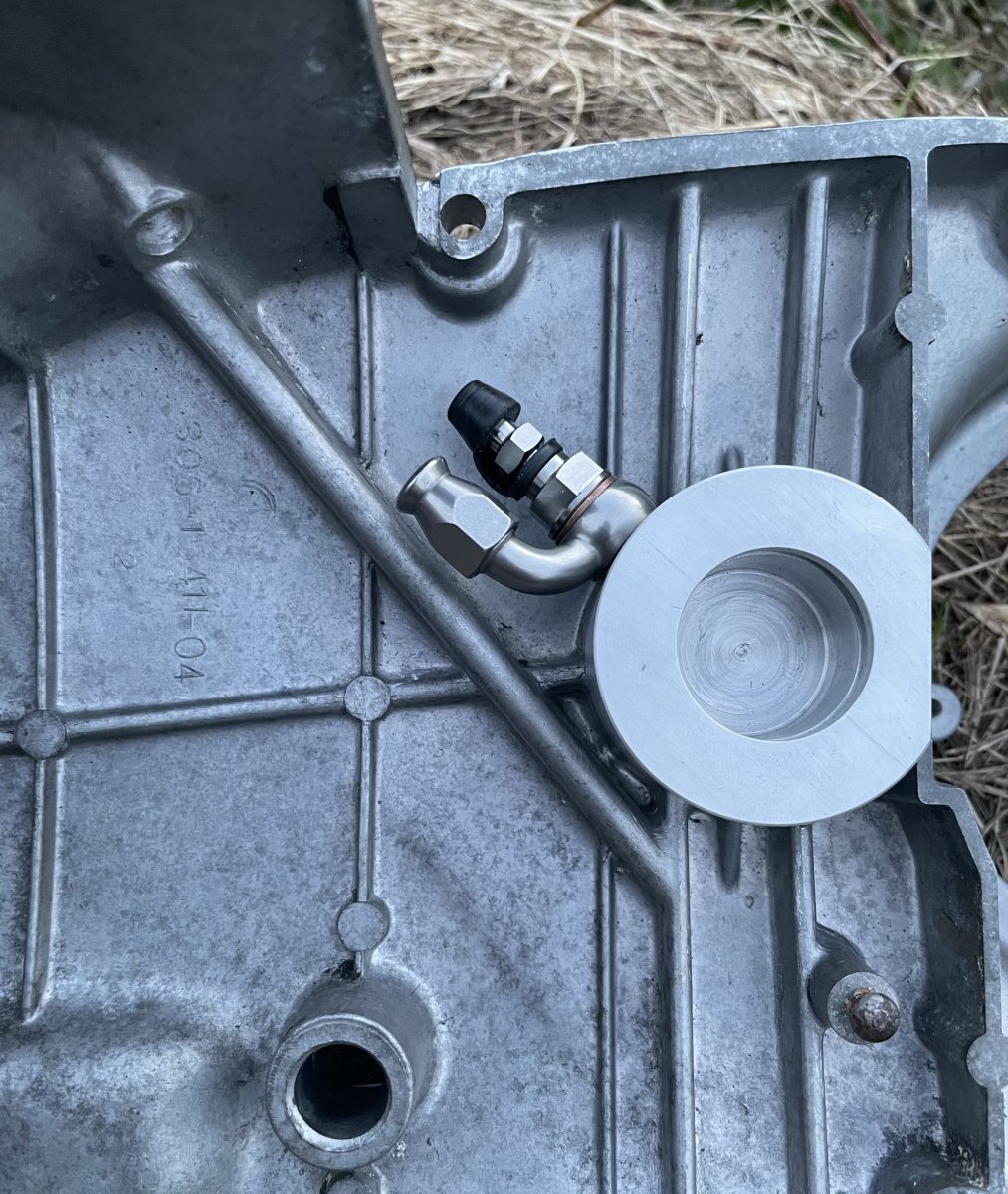

So here we go gentlemen...

A couple caveats.

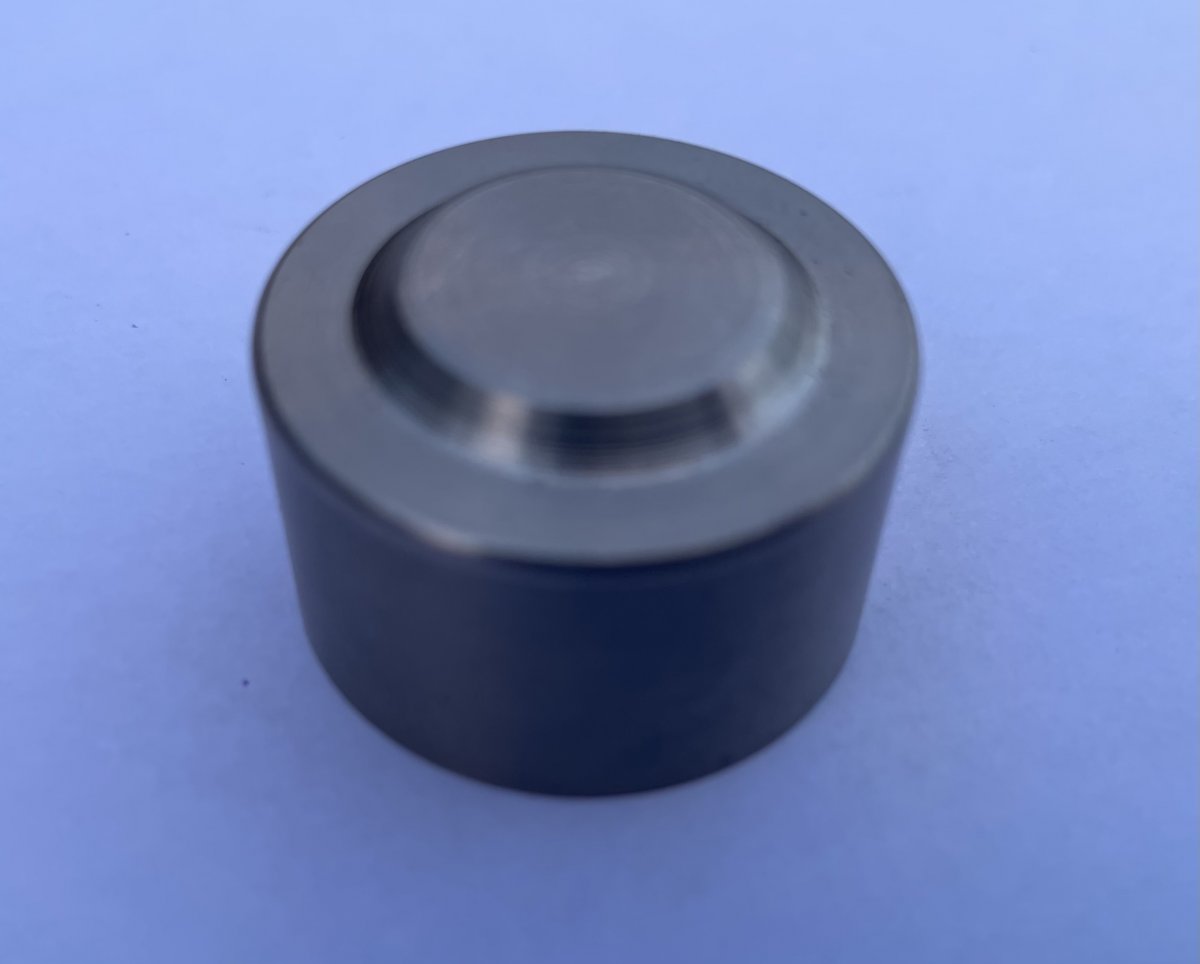

Firstly the ‘cap’ we have here is Titanium, all others will be 6082 the same as the slave body, I wanted mine to be Titanium as I’ve so many external parts of the engine machined from Titanium I felt it would look out of place if it was Aluminium.

Secondly the recess for the countersunk bolt needs machining a little more for it to be able to sit fully flush. We didn’t have the bolts to hand as they only arrived today.

I hope everyone likes what they see! Please don’t hesitate offering any feedback.

Cheers guys.

Daniel.

A couple caveats.

Firstly the ‘cap’ we have here is Titanium, all others will be 6082 the same as the slave body, I wanted mine to be Titanium as I’ve so many external parts of the engine machined from Titanium I felt it would look out of place if it was Aluminium.

Secondly the recess for the countersunk bolt needs machining a little more for it to be able to sit fully flush. We didn’t have the bolts to hand as they only arrived today.

I hope everyone likes what they see! Please don’t hesitate offering any feedback.

Cheers guys.

Daniel.

Looks awesome Daniel.

Looks awesome Daniel.

Thanks Jim, it means a lot coming from you!

I’m liking it! Will you be supplying the banjo and bleeder? Would be nice as it may difficult to source for some people (like me  ).

).

Brilliant. There are so many clever little design features in there, I love it. The angle of the banjo (will need to consider how best to bleed?) matching the stock clutch cable, the little hex standoffs in place of the stock screws for a simple install, the very robust-looking attachment cap (which I'm sure will look even better when the countersink is optimized).

Very well done

Very well done

I’m liking it! Will you be supplying the banjo and bleeder? Would be nice as it may difficult to source for some people (like me).

Hey @bosco659

I do plan on supplying them with a one piece banjo & bleed fitment.

The one in the photo is Titanium but I’ll supply with a Stainless counterpart.

The assembly will also come with Stainless M8 countersunk bolt, Rubber dust cap, Copper crush washers, Stainless grub screws, Stainless oil seal & Stainless ball bearing.

Last edited:

Brilliant. There are so many clever little design features in there, I love it. The angle of the banjo (will need to consider how best to bleed?) matching the stock clutch cable, the little hex standoffs in place of the stock screws for a simple install, the very robust-looking attachment cap (which I'm sure will look even better when the countersink is optimized).

Very well done

Thanks @SomervilleXS650, I’m glad you like it! A lot of thought, effort & time’s gone into this and I’m pleased it’s not gone unnoticed.

Can’t wait for you to have #001

I'll allow it

Sounds great. Can’t wait for the test results. Of the list of people interested in this, do any of them have the 8 plate clutch mod?Hey @bosco659

I do plan on supplying them with a one piece banjo & bleed fitment.

The one in the photo is Titanium but I’ll supply with a Stainless counterpart.

The assembly will also come with Stainless M8 countersunk bolt, Rubber dust cap, Copper crush washers, Stainless grub screws, Stainless oil seal & Stainless ball bearing.

ShaggyMech

Socal Mechanic.

ShaggyMech Please start a build thread for your EFI bike. I any no doubt others would be very keen to follow your progress.

I plan to start a build thread for my bikes as I get closer to completion on a few of them my 82 heritage is an ongoing project but I have a blue 80 model that will be my EFI testbed. I have 3 other xs650 that will be getting various treatments from brat, cafe, and tracker. My Heritage will stay somewhat mild in looks But I do plan to run mikuni rs 34 carbs and put together A 750 kit to build a screaming motor on top of that. Internally though that engine will be as custom as I can get R1 clutch components hopefully slipper, Titanium valve train custom cut camshaft hopefully a roller rocker assembly if I can design one that is appropriate, I also planned to undercut and cryo the transmission take every bushing and convert to bearing and any other surface will be treated to whatever I can do to make that the most smooth running and best performing xs motor out there

Sounds great. Can’t wait for the test results. Of the list of people interested in this, do any of them have the 8 plate clutch mod?

I have 8 packs on both my motors currently

I plan to start a build thread for my bikes as I get closer to completion on a few of them my 82 heritage is an ongoing project but I have a blue 80 model that will be my EFI testbed. I have 3 other xs650 that will be getting various treatments from brat, cafe, and tracker. My Heritage will stay somewhat mild in looks But I do plan to run mikuni rs 34 carbs and put together A 750 kit to build a screaming motor on top of that. Internally though that engine will be as custom as I can get R1 clutch components hopefully slipper, Titanium valve train custom cut camshaft hopefully a roller rocker assembly if I can design one that is appropriate, I also planned to undercut and cryo the transmission take every bushing and convert to bearing and any other surface will be treated to whatever I can do to make that the most smooth running and best performing xs motor out there

Where's the build thread so everyone can discuss with you

Similar threads

- Replies

- 25

- Views

- 2K