I ordered an air/fuel metering kit for my Harley (for the record I own 3 XS's to my 1 Harley) to dial in the carb with new pipes I bought. That kit came with several electrical connectors that I had never seen before. Had to look it up, as they seem to be very well made and high quality. Thought someone else here could benefit from having good options for easy solderless connectors.....

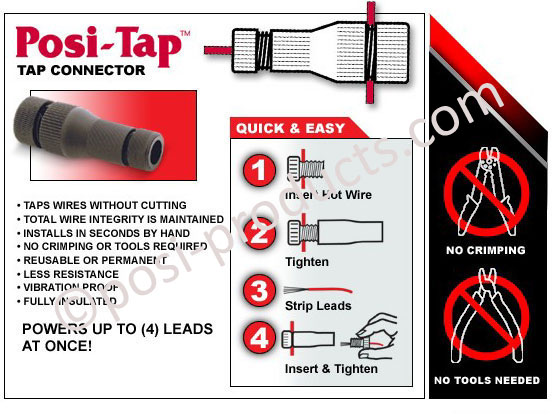

The ones I have are called "positaps", and allow you to connect into any existing wire without cutting the wire, crimping, or soldering. It has a sharp pin on one end that inserts itself onto an existing wire without compromising the integrity of the wire:

https://www.posi-products.com/posiplug.html

The ones I have are called "positaps", and allow you to connect into any existing wire without cutting the wire, crimping, or soldering. It has a sharp pin on one end that inserts itself onto an existing wire without compromising the integrity of the wire:

https://www.posi-products.com/posiplug.html