Djfknwoo

XS650 Enthusiast

Hey everyone been lurking here for a while and finally I have decided to just make a post about my problem. A little info about my bike

1979 xs650 special

Points ignition

New coils and condenser

New carb boots with no vacuum ports

New petcocks (on, off, reserve)

Xs charge system with capacitor (kick only)

New spark plugs and wires and plug ends

Basically what has happened is on Sunday I went for a ride everything seemed great ran well no back firing no sputtering rode for 2 hours straight.

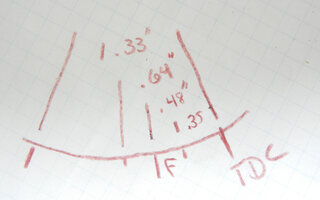

Next day I went to start the bike and it appeared to only be running on the right cylinder the left only seemed to get hot after I raised the throttle to 2500 -3500 rpm and it would occasionally backfire out the exhaust and sometimes the left carb. I have tried switching the plug wires to see if it was a bad coil and it still didn't fix the issue. I've had the carbs off 3 times cleaned them and used a air compressor to blast out the jets and corresponding ports and it doesn't seem to make a difference. When idling I can pull off the left plug wire and the bike will run fine off the right cylinder but if I pull the right plug to test the left side it just immediately dies. Is anyone able to point me in the right direction? Thanks in advance

1979 xs650 special

Points ignition

New coils and condenser

New carb boots with no vacuum ports

New petcocks (on, off, reserve)

Xs charge system with capacitor (kick only)

New spark plugs and wires and plug ends

Basically what has happened is on Sunday I went for a ride everything seemed great ran well no back firing no sputtering rode for 2 hours straight.

Next day I went to start the bike and it appeared to only be running on the right cylinder the left only seemed to get hot after I raised the throttle to 2500 -3500 rpm and it would occasionally backfire out the exhaust and sometimes the left carb. I have tried switching the plug wires to see if it was a bad coil and it still didn't fix the issue. I've had the carbs off 3 times cleaned them and used a air compressor to blast out the jets and corresponding ports and it doesn't seem to make a difference. When idling I can pull off the left plug wire and the bike will run fine off the right cylinder but if I pull the right plug to test the left side it just immediately dies. Is anyone able to point me in the right direction? Thanks in advance

Last edited: