-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Real Estate Update

- Thread starter Downeaster

- Start date

There's only 2 remaining and their getting old

Maybe one of them has a drip

Maybe one of them has a drip

Probably planning to park a Brit Bike in there...What's with the poly on the floor

Block moisture coming up?What's with the poly on the floor

@jetmechmarty wins the prize. Before I started to keep the garage warm, a lot of moisture would come up through the concrete. The plastic was intended to keep the moisture away from the underside of the cars. Now there’s heat (above freezing) and there’s no condensation under the plastic as there used to be. I’m putting in a dehumidifier today to see what’s in the air in there.What's with the poly on the floor

No oil leaks other than my small hydraulic floor jack. Maybe I should buy a Brit bike. Lol.

Heater mounted to wall. 4KW, keeps it nice and warm (until I see my electricity bill for last month).

Stuck the dehumidifier in the garage and ran it for several hours. Not a drop came out even with the control set to 35%. Appears to be very low humidity in there

I used concrete sealer in my basement, and Stay-Dry masonry paint on the concrete walls. Went from emptying the dehumidifier from twice a day to once a month.

PS.

Actually while you think of concrete as being waterproof, or water tight, swimming pools are made of it, it's amazing how much moisture actually passes through it.

My parents had a small place in retirement community in Bradenton Florida adjacent to the Braden river. Mom stored things in plastic boxes under the bed and when she pulled something out the carpet beneath would be damp. After dad passed and we moved mom into assisted living. My wife, my brother and I went down to clear the place out. There was white mold film on the walls, if you looked along them you could see it and if you run your hand over the wall you could feel it though not see it looking straight at the wall.

We brought in a company to rent it to help pay her expenses, first thing they did was clean, repaint and then tile the floors throughout with vitreous ceramic tiles.

PS.

Actually while you think of concrete as being waterproof, or water tight, swimming pools are made of it, it's amazing how much moisture actually passes through it.

My parents had a small place in retirement community in Bradenton Florida adjacent to the Braden river. Mom stored things in plastic boxes under the bed and when she pulled something out the carpet beneath would be damp. After dad passed and we moved mom into assisted living. My wife, my brother and I went down to clear the place out. There was white mold film on the walls, if you looked along them you could see it and if you run your hand over the wall you could feel it though not see it looking straight at the wall.

We brought in a company to rent it to help pay her expenses, first thing they did was clean, repaint and then tile the floors throughout with vitreous ceramic tiles.

Last edited:

Well, its been quite a while since I had time to post anything other than some good jokes (I really do like the paycheques - but working really is a drag). However, I do have a moment this morning - and the Great Canadian Pole Barn project reached a major milestone just yesterday!

WE HAVE HEAT!!!

The natural gas line was connected to the teeny little boiler and the system was started-up and is pumping nice hot glycol-water mix through the hundreds of feet of plastic piping buried in the concrete floor. These systems cannot change the temperature quickly due to their relatively low power and the immense thermal inertia of the concrete floor, but once the temperature is up, things stay warm and they don't use a lot of energy....as long as the structure is well-insulated.

The photo below was taken in late August when the heating pipe system was installed. The gray stuff under the pipes is 3” styrofoam to which the pipes are attached with special staples. After the pipes are down, the concrete guys came and poured the 4-5” floor, thus burying the pipe system.

There is 3" of styrofoam insulation below the concrete, R60 in the ceiling and the walls will be <I think>, about R40 when they're done - so it should be pretty cheap and easily to keep comfy.

NEXT STEPS: install the six big LED ceiling lights and two 60" fans for de-stratification of the air mass in the building, then insulate the walls, install the vapour barrier and interior siding and in the spring - a 2-ton / 24,000 BTU mini-split AC-heat pump unit.

We're gettin' there!

Cheers all,

Pete

WE HAVE HEAT!!!

The natural gas line was connected to the teeny little boiler and the system was started-up and is pumping nice hot glycol-water mix through the hundreds of feet of plastic piping buried in the concrete floor. These systems cannot change the temperature quickly due to their relatively low power and the immense thermal inertia of the concrete floor, but once the temperature is up, things stay warm and they don't use a lot of energy....as long as the structure is well-insulated.

The photo below was taken in late August when the heating pipe system was installed. The gray stuff under the pipes is 3” styrofoam to which the pipes are attached with special staples. After the pipes are down, the concrete guys came and poured the 4-5” floor, thus burying the pipe system.

There is 3" of styrofoam insulation below the concrete, R60 in the ceiling and the walls will be <I think>, about R40 when they're done - so it should be pretty cheap and easily to keep comfy.

NEXT STEPS: install the six big LED ceiling lights and two 60" fans for de-stratification of the air mass in the building, then insulate the walls, install the vapour barrier and interior siding and in the spring - a 2-ton / 24,000 BTU mini-split AC-heat pump unit.

We're gettin' there!

Cheers all,

Pete

Last edited:

Very nice! That will keep you nice and cozy all year round! Congrats!Well, its been quite a while since I had time to post anything other than some good jokes (I really do like the paycheques - but working really is a drag). However, I do have a moment this morning - and the Great Canadian Pole Barn project reached a major milestone just yesterday!

WE HAVE HEAT!!!

View attachment 233338

The natural gas line was connected to the teeny little boiler and the system was started-up and is pumping nice hot glycol-water mix through the hundreds of feet of plastic piping buried in the concrete floor. These systems cannot change the temperature quickly due to their relatively low power and the immense thermal inertia of the concrete floor, but once the temperature is up, things stay warm and they don't use a lot of energy....as long as the structure is well-insulated.

View attachment 233336

There is 3" of styrofoam insulation below the concrete, R60 in the ceiling and the walls will be <I think>, about R40 when they're done - so it should be pretty cheap and easily to keep comfy.

View attachment 233337

NEXT STEPS: install the six big LED ceiling lights and two 60" fans for de-stratification of the air mass in the building, then insulate the walls, install the vapour barrier and interior siding and in the spring - a 2-ton / 24,000 BTU mini-split AC-heat pump unit.

We're gettin' there!

Cheers all,

Pete

That's the direction I wish I would have went

I have no insulation under the floor walls are just standard fiber glass insulation

I did blow in r60 cellulose in the ceiling with plenty of ventilation but just a standard natural gas hang on the ceiling heater

Save a penny pay a buck later

I have no insulation under the floor walls are just standard fiber glass insulation

I did blow in r60 cellulose in the ceiling with plenty of ventilation but just a standard natural gas hang on the ceiling heater

Save a penny pay a buck later

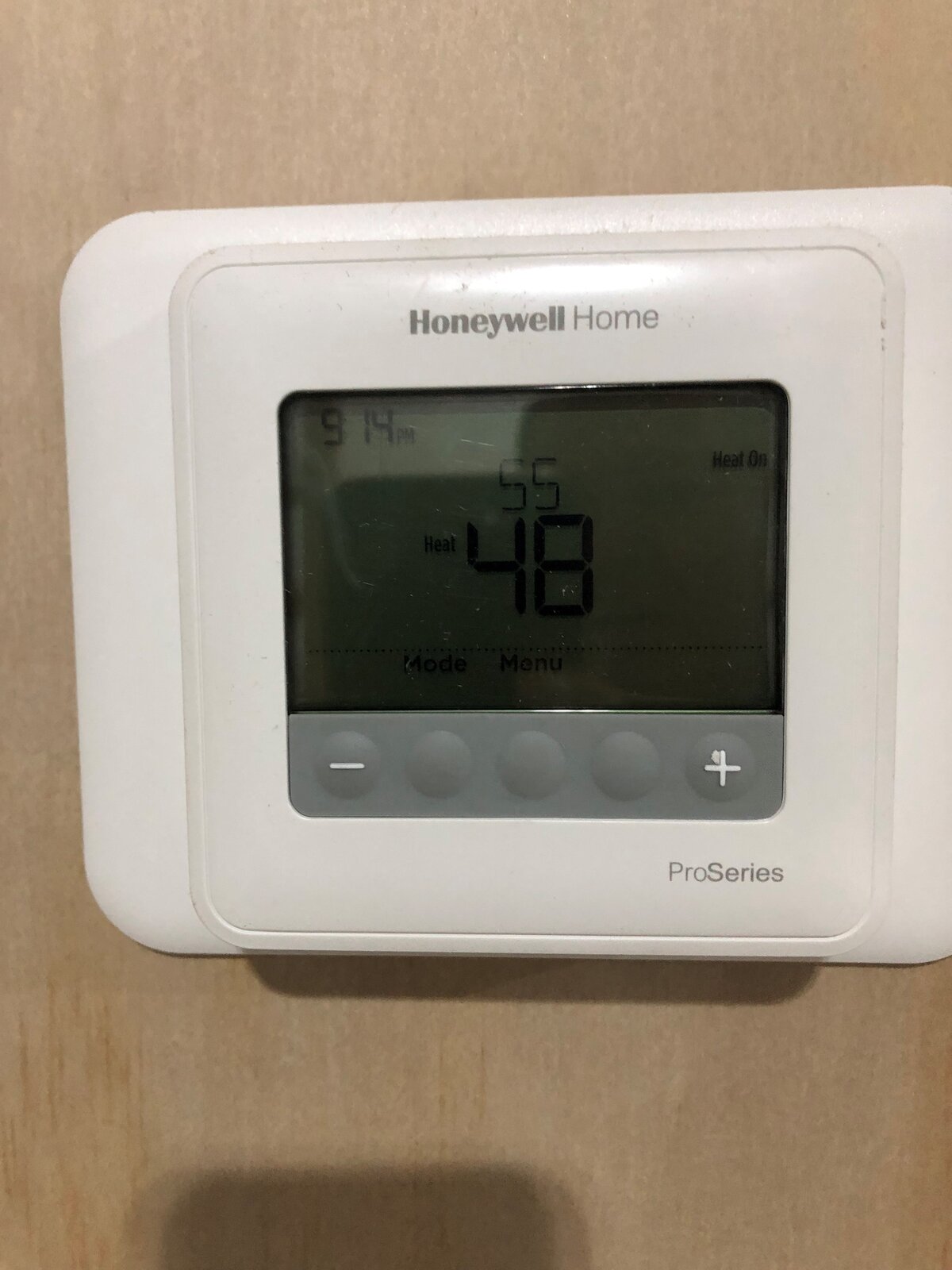

No Grimly: that is the air temperature at the thermostat (49 deg. F) and the temperature set-point (55 deg. F). The system was started at about 4:00 pm and that photo was taken about 5 hours later at 9:17 pm or so. The actual water temperature is not monitored - at least as far as I know. Also the little fluid pump and the boiler are both virtually silent - at least, I haven’t heard a single sound out of the system at all.Is that the input / flow temp of the heating feed pipe?

The nature of these system is that they react pretty slowly because the heat (or more correctly, the energy) must transfer from the fluid to the concrete mass and then from the surface of the floor into the air. By the time I checked the next morning, the air temp matched the set-point exactly and it hasn’t wavered all weekend. By the way, 55 deg. F is perfectly comfortable for me to work in a tee-shirt - although it would be too chilly for lounging around reading or watching TV. It’s going to be even better when I get the walls of the building insulated.

The water is going into the floor MUCH hotter than the setpoint - but as I noted above, I have no idea exactly how hot, but I’d bet it would burn if you had a burst pipe. As I said above, the thermal inertia of the system is very large so it take a looooong time to heat the air up - but once things are warm, they will stay warm as long as you don’t open a door. If the big door is opened, the cold air would rush in and again, the system would take quite a while to warm it up again.

However, this is a barn / workshop and not a garage so I’d guess that the big overhead door won’t be open very often or for very long - particularly during heating season.

Once the AC / heat pump unit goes in in a few months, the air temperature will recover much more quickly with it.

And yesterday, we achieved two more major milestones! I finally got the two 60” ceiling fans hoisted up and the big 150W / 21,000 lumen LED light fixtures going - 6 of ‘em and holy cow, are they bright! There will be no shadows. The fans will be powered up as soon as I can run a new circuit from the breaker panel - this week for sure.

Cheers,

Pete

Last edited:

Looking good

Pete I would be very interested in knowing the temp of the liquid going into the floor.Also the little fluid pump and the boiler are both virtually silent - at least, I haven’t heard a single sound out of the system at all.

Looking good Pete!

Ah, you're using those fiddly Murcan units, which surprised me.No Grimly: that is the air temperature at the thermostat (49 deg. F)

In proper Napoleonic units, that wouldn't have been far off the input temp.

Not trying to hijack but all this talk about shops and work spaces really got me thinking. Since a few days before Christmas I’ve been in the Garage every day “remodeling”. I realized that not having a shop building was just the way it’s gonna be so I better figure out what to do with what I have. I have emptied and gone through every cabinet, shelf and toolbox and eliminated most of the clutter I’ve let happen over the years. I literally have empty cabinets and drawers in my tool boxes Now that I’ve realized I don’t need 12 Channelock pliers, many brands of screwdrivers in the same size and just any tools I’ve never used. I had way to many duplicates and more of tools. Luckily the oldest and his fiancé just bought a house so he starts out with a full standup box and plenty of power tools I took the main assembly table from the middle of the garage that was taking up most of the space, cut it in half and re-installed as a bench. I’ve pretty much gone through everything I have and reworked drawers to a point where I’m down to sorting out the junk in my organizers.

Pete I would be very interested in knowing the temp of the liquid going into the floor.

Install quite a few infloor systems these days, always run our water temps right around 120-125deg

Without exaggeration I probably own 125+ screwdrivers and I keep buying more. Same for pliers, hammers, sockets, ratchets….. Do you think I have a problem?Not trying to hijack but all this talk about shops and work spaces really got me thinking. Since a few days before Christmas I’ve been in the Garage every day “remodeling”. I realized that not having a shop building was just the way it’s gonna be so I better figure out what to do with what I have. I have emptied and gone through every cabinet, shelf and toolbox and eliminated most of the clutter I’ve let happen over the years. I literally have empty cabinets and drawers in my tool boxes Now that I’ve realized I don’t need 12 Channelock pliers, many brands of screwdrivers in the same size and just any tools I’ve never used. I had way to many duplicates and more of tools. Luckily the oldest and his fiancé just bought a house so he starts out with a full standup box and plenty of power tools I took the main assembly table from the middle of the garage that was taking up most of the space, cut it in half and re-installed as a bench. I’ve pretty much gone through everything I have and reworked drawers to a point where I’m down to sorting out the junk in my organizers.View attachment 233459View attachment 233461View attachment 233458View attachment 233460

Similar threads

- Replies

- 31

- Views

- 3K