Man I just love your bike...do you have a build thread on it?Welcome, XS650s are good therapy and non stock, Trackers, and others have been welcomed here...

View attachment 237345

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1976 XS650C Café Racer Build

- Thread starter mrob24

- Start date

Hello, All. I'm a new member to the page, although I've read countless threads since picking up my 1976 650 approximately six months ago. I'm in bonnie Scotland. What a brilliant resource this forum is. The depth and wealth of knowledge contained within is such a fantastic help, and the community seems top notch. It's good to be here!

I'm 34, road riding for 14 years, although started my riding aged eight on my TY80 stroker trials bike. I guess bikes are in the blood, as they say: my dad raced Yamaha RDs for many years, my uncle raced, my mum used to ride (she wouldn't date a guy unless he had long hair and a bike, so she tells me, how she ended up with my dad!), and my great grandfather raced pretty successfully at the Isle of Man TT for many years. There's a collection of silverware in the family.

I have a Yamaha MT-10, which is a weapon and a hoot, and picked my XS up last year - my first foray into the world of classics, inspired by my old man's recently completed Triton 750 twin build (took him 30 years, he blames kids etc...). I bought my XS in a sort of pseudo-tracker guise. I'm cafe-ing it (I understand this will generate abuse from purists, however I really just wanted to get seriously stuck into something that'd require a good bit of work). I strugggle quite severely with my mental health t times, and spending evenings in the garage getting in over my head is the most wonderful therapy. It's been such a great distraction to be stuck into something creative, and challenging.

Anyway, sorry for rambling. Below are some pictures of what I've been up to. I look forward to contributing and continuing to learn from you all everyday.

All the best,

Cheers. View attachment 237224View attachment 237225View attachment 237226View attachment 237227

Thank you. The thread is "New to me XS650". I bought the bike 18 months ago. It was a well presented but "unfinished" beauty. It needed brake work, carb tuning, electrical work,clutch work and a few other things. With the help of this forum I have been able to develop it into a rewarding daily rider.Man I just love your bike...do you have a build thread on it?

There are all form of XS650s here and I enjoy them all. Pics are appreciated.

Welcome from the Colonies. Being a purist is highly overrated.

In case they forgot to tell ya... we love pics here.

In case they forgot to tell ya... we love pics here.

A learning and PhD primer on XS650 doctoral.....do you have a build thread on it?

How to take a good looking bike in to a good running bike...

mrob24

XS650 Member

Thanks again, chaps, for such a lovely welcome to the forum. I'm genuinely excited to keep at this build, and to document it here for you all to input and feedback on. As I said, an incredible community and depth of knowledge. It'll all be tapped into in due course, I'm sure...!

Cheers,

Mark

Cheers,

Mark

mrob24

XS650 Member

That's a cracker, Kevin. I'm loving my build so much that I'm already thinking of buying another XS650 once this cafe project is 'finished' (hmm...) to undertake a tracker build. I love the style.Welcome, XS650s are good therapy and non stock, Trackers, and others have been welcomed here...

View attachment 237345

mrob24

XS650 Member

5Twins, are you man or machine?! I'm pretty new here, but already I'm aware that you are a living XS650 encyclopedia (and probably encyclopedic about many other things, too)! Thank you for this excellent advice, and the detailed photographs. It's very timeous, too, as I am about to rebuild my swinging arm today. The grease nipple you've fitted at the central gusset looks larger than those at the ends of the swinging arm through bolt; is there any particular size you'd recommend? Looks like a 45 degree nipple. I've ordered new sprockets, and a new chain (staying with the 530 set-up). I've gone for 17/33.Welcome. Boy, you really dove in with both feet, lol. Yes, these bikes benefit greatly from a small gearing change, but only a small one. You have to keep in mind we're only dealing with about a 50 HP machine here so if you gear it too high, it won't pull redline in 5th. Plus, you kill the bike's "fun factor", the wonderful midrange "lunge" it has in the lower gears. I find that 17-33 gearing is ideal for an 18" rear wheel, 17-32 works well with a 16" rear wheel. Personally, I feel a 30T rear sprocket is too small. If you want to cruise down the highway all day long at 80, buy a BMW, lol. That's not what this bike is about.

A couple more little tips - you'll want to install a grease nipple on the middle bottom side of the swingarm for those new bronze bushings. They are designed to get their grease supply from the rear, not the side like the original bushings. Install the fitting at the edge of the gusset plate. You need the added thickness of the plate so the fitting doesn't stick too far into the arm and hit the pivot tube .....

View attachment 237255

You can also do a small mod to that pivot tube. Drill a couple more holes through it at the center (red arrows) .....

View attachment 237257

View attachment 237258

View attachment 237259

This will allow grease pumped into the original grease fittings on the ends of the pivot bolt to get into the center of the arm and to the backs of the new bushings .....

View attachment 237260

This mod alone may be enough to get the new bushings properly greased but I do both.

Next, your '76 motor most likely has the type C cam chain adjuster, the one with no lock nut. I would recommend upgrading it to the later type E adjuster. Details are here in posts 22 and 23 .....

https://www.xs650.com/threads/cam-chain-tensioners.1056/page-2

Interestingly, while looking at the front sprocket last night, it became clear that the clutch pushrod is bent... Looks like I'll be replacing it, and I'll do the bush and seal while I'm at it because the rod has clearly had significant lateral force on it at some point. I was also surprised to find that my bike ('76) has the single unit long push rod installed.

Thank you, Mark

Last edited:

Not important, and I'm sure there are plenty here to correct me if I'm wrong, but I think your bike is the 1975 colour scheme? The V5 would say 1976 if that's when it was registered.

Wot has happened to that push rod - was the clutch still working ok? IMO the clutches on these bikes are good but they are slightly finicky for getting the adjustment right - plenty of advice on the forum or ask.

Here is Miss November and a link to my sorting-out thread - have a look through the pictures but dinnae bother reading all the ins and outs:

https://www.xs650.com/threads/miss-november-xs2-tribute.55057/post-735139

I benefitted from a lot of invaluable help from 5Twins and a lot of other people - you are dead right this is a good community, loads of knowledge loads of help and advice freely given. The folk on this forum know more about the XS650 than the people who built them back in the day.

Wot has happened to that push rod - was the clutch still working ok? IMO the clutches on these bikes are good but they are slightly finicky for getting the adjustment right - plenty of advice on the forum or ask.

Here is Miss November and a link to my sorting-out thread - have a look through the pictures but dinnae bother reading all the ins and outs:

https://www.xs650.com/threads/miss-november-xs2-tribute.55057/post-735139

I benefitted from a lot of invaluable help from 5Twins and a lot of other people - you are dead right this is a good community, loads of knowledge loads of help and advice freely given. The folk on this forum know more about the XS650 than the people who built them back in the day.

Yep, '75 color scheme.

Pushrod looks bent right where the chain would hit it. Like Raymond says, clutch adjustment can be finicky AND if the clutch assembly has ever been worked on by a novice (?) it's easy enough to get the washers and flat bearings out of order.....it may work but not well.

Pushrod looks bent right where the chain would hit it. Like Raymond says, clutch adjustment can be finicky AND if the clutch assembly has ever been worked on by a novice (?) it's easy enough to get the washers and flat bearings out of order.....it may work but not well.

Warning: Thats exactly how the XS650 hoarding starts.That's a cracker, Kevin. I'm loving my build so much that I'm already thinking of buying another XS650 once this cafe project is 'finished' (hmm...) to undertake a tracker build. I love the style.

You buy one as a daily rider, then one to build as a cafe racer, another to build as a street tracker...and so on and so on.

The grease fittings I use are the standard M6 size, same as the ones fitted to the bike from the factory. The 45° base probably makes it look bigger than it is. I got an assortment kit from the auto parts store. It contained normal straight fittings along with some 45's and 90's .....

https://www.autozone.com/collision-...ormance-tool-metric-grease-fitting/142107_0_0

I use the 45° fitting because it makes it easier to access once the swingarm is in place .....

I would get another long pushrod as a replacement but I can't recommend the aftermarket ones. Many aren't hardened properly on the ends and wear quickly .....

Instead, watch eBay for a N.O.S. original, they pop up all the time and can usually be had for around the same price as those inferior aftermarket ones.

https://www.autozone.com/collision-...ormance-tool-metric-grease-fitting/142107_0_0

I use the 45° fitting because it makes it easier to access once the swingarm is in place .....

I would get another long pushrod as a replacement but I can't recommend the aftermarket ones. Many aren't hardened properly on the ends and wear quickly .....

Instead, watch eBay for a N.O.S. original, they pop up all the time and can usually be had for around the same price as those inferior aftermarket ones.

I had so much fun being tutored by this board that now that the tracker is a good running rider I am building a standard style from an 81 Special.That's a cracker, Kevin. I'm loving my build so much that I'm already thinking of buying another XS650 once this cafe project is 'finished' (hmm...) to undertake a tracker build. I love the style.

mrob24

XS650 Member

Further great advice from you all above, thank you. I'll keep an eye out for an NOS pushrod.

A bit more progress this morning. I got my bits and bobs back from the powder coater on Friday, lovely job. I had the disc carrier coated gloss black, drilled the rotor to assist with water dispersion (handy when living and riding in the soaking North East coast of Scotland). That was a pain in the backside, even with a drill press and cobalt bits. I used high tensile button head bolts and Nyloc nuts to put it back together - didn't like the aesthetic of the hex head bolts and lock tabs.

I also rebuilt my forks this morning. The legs were powder coated gloss black, too. New seals, 15wt Motul fork oil (did the increased volume thing, approximately 165ml oil per leg (34mm forks), filled the stanchion to 5,3/4 inch from the top with the fork fully compressed and spring removed. We'll see... It was a bugger tightening the damper rod bolt with my steel tube 'tool'. My damper rod has the 12mm diameter rounds with the 10mm across flats. The steel tube walls of the tool are only 1mm thick so they were deforming under the tightening torque. I got them nipped up to around 22Nm which I imagine will be adequate with the copper sealing washer. Again, we'll see...

My order from Heiden Tuning, NL, inclusive of bronze bushes, is currently a week late so I can't get the swinging arm back together yet. At the Scottish Motorcycle Show yesterday I picked up a set of Avon Roadriders MkII (100/90/19; 110/90/18) and a pair of Hagon shocks.

Here's a question: how manageable is it to polish OE aluminium flanged rims to a fairly high polish finish (not mirror) if I get them vapour blasted first to clean them up and remove the lacquer? I sent the rims and hubs to a lad up north to polish them. He quoted me £400(!) which seemed crazy to me. I could just about buy brand new rims and hubs for that price. I'm thinking I might get them vapour blasted then go at them with fine sand and Autosol.

Cheers,

Mark

A bit more progress this morning. I got my bits and bobs back from the powder coater on Friday, lovely job. I had the disc carrier coated gloss black, drilled the rotor to assist with water dispersion (handy when living and riding in the soaking North East coast of Scotland). That was a pain in the backside, even with a drill press and cobalt bits. I used high tensile button head bolts and Nyloc nuts to put it back together - didn't like the aesthetic of the hex head bolts and lock tabs.

I also rebuilt my forks this morning. The legs were powder coated gloss black, too. New seals, 15wt Motul fork oil (did the increased volume thing, approximately 165ml oil per leg (34mm forks), filled the stanchion to 5,3/4 inch from the top with the fork fully compressed and spring removed. We'll see... It was a bugger tightening the damper rod bolt with my steel tube 'tool'. My damper rod has the 12mm diameter rounds with the 10mm across flats. The steel tube walls of the tool are only 1mm thick so they were deforming under the tightening torque. I got them nipped up to around 22Nm which I imagine will be adequate with the copper sealing washer. Again, we'll see...

My order from Heiden Tuning, NL, inclusive of bronze bushes, is currently a week late so I can't get the swinging arm back together yet. At the Scottish Motorcycle Show yesterday I picked up a set of Avon Roadriders MkII (100/90/19; 110/90/18) and a pair of Hagon shocks.

Here's a question: how manageable is it to polish OE aluminium flanged rims to a fairly high polish finish (not mirror) if I get them vapour blasted first to clean them up and remove the lacquer? I sent the rims and hubs to a lad up north to polish them. He quoted me £400(!) which seemed crazy to me. I could just about buy brand new rims and hubs for that price. I'm thinking I might get them vapour blasted then go at them with fine sand and Autosol.

Cheers,

Mark

mrob24

XS650 Member

Hello again, fellas. It's been a while since I've updated anything, however I've been doing lots of reading and making a fair bit of progress (with the odd two steps backwards for one forwards).

I've changed the thread title to make this my build thread as I couldn't be arsed starting a new thread to cover previous ground again. So, since I last wrote anything, here's what I've been up to. Plenty grins, and plenty gremlins along the way...

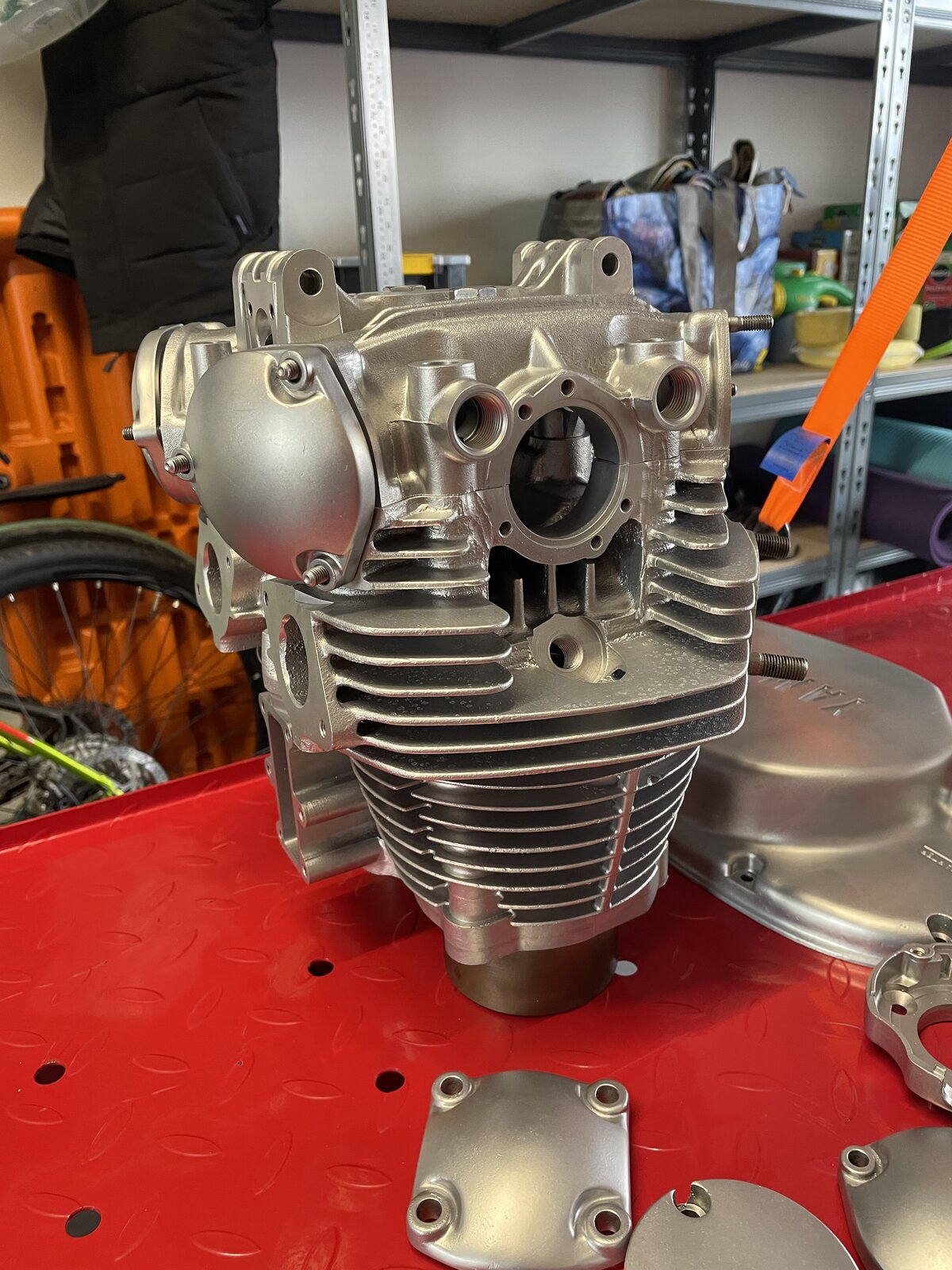

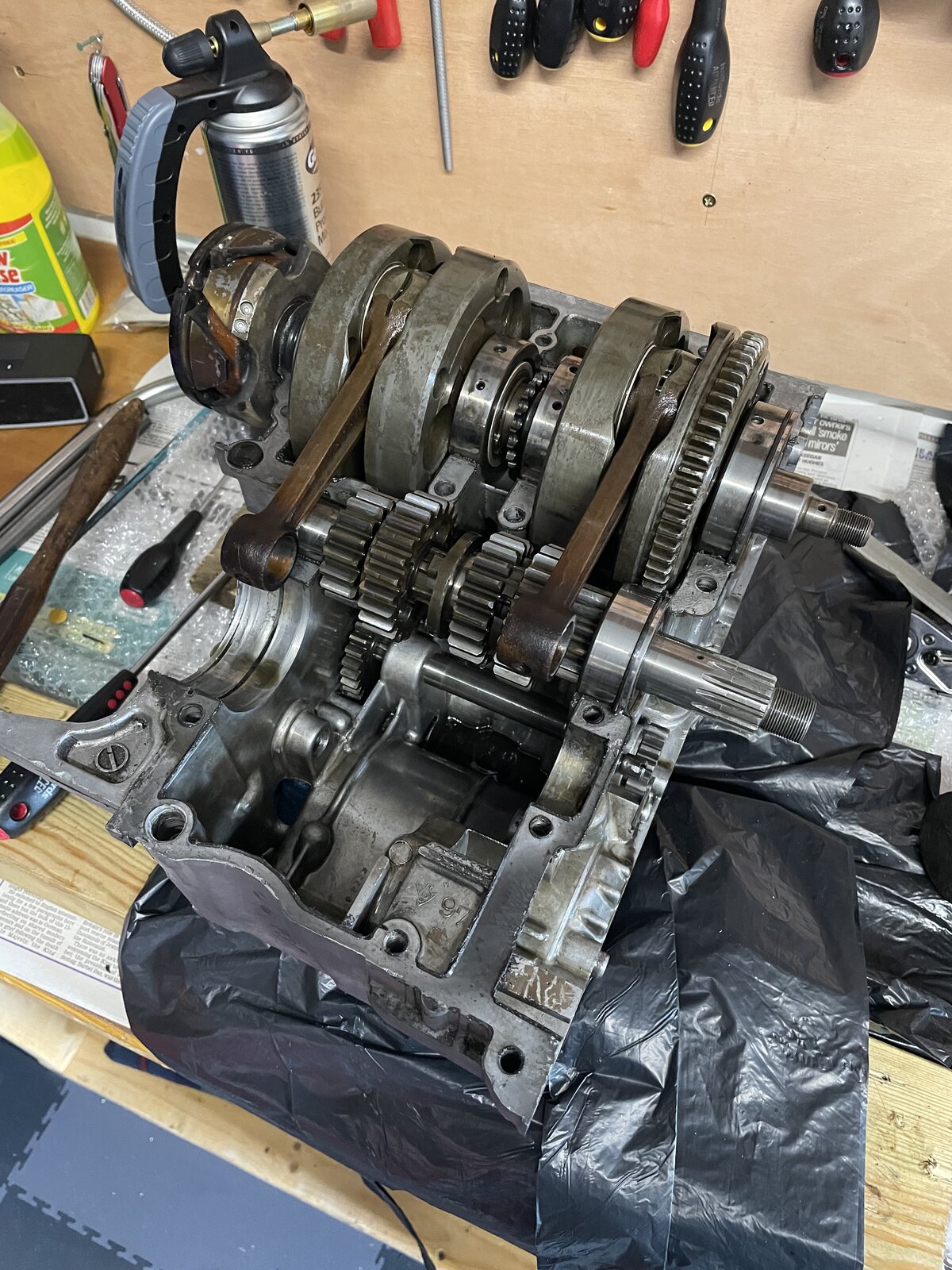

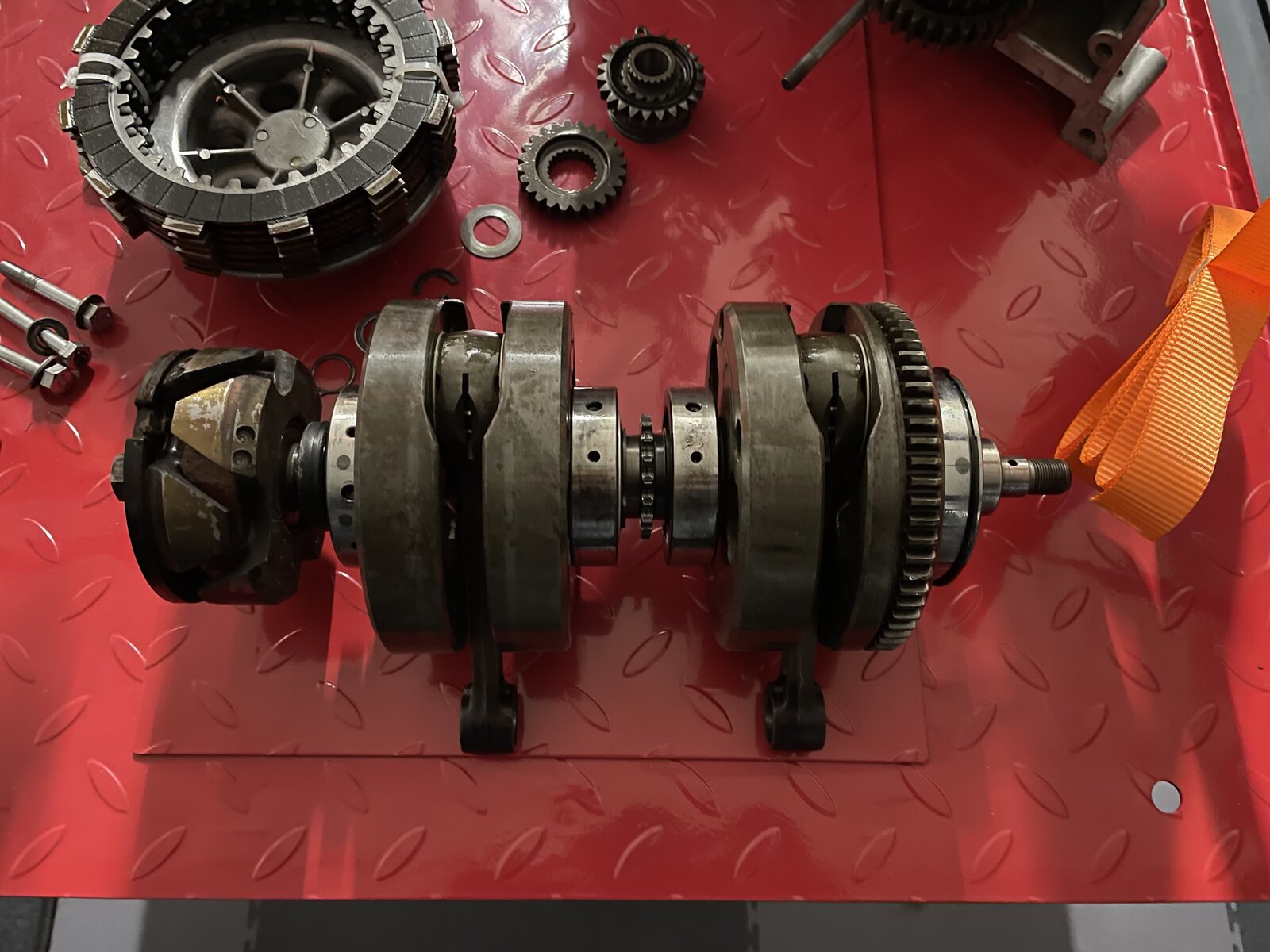

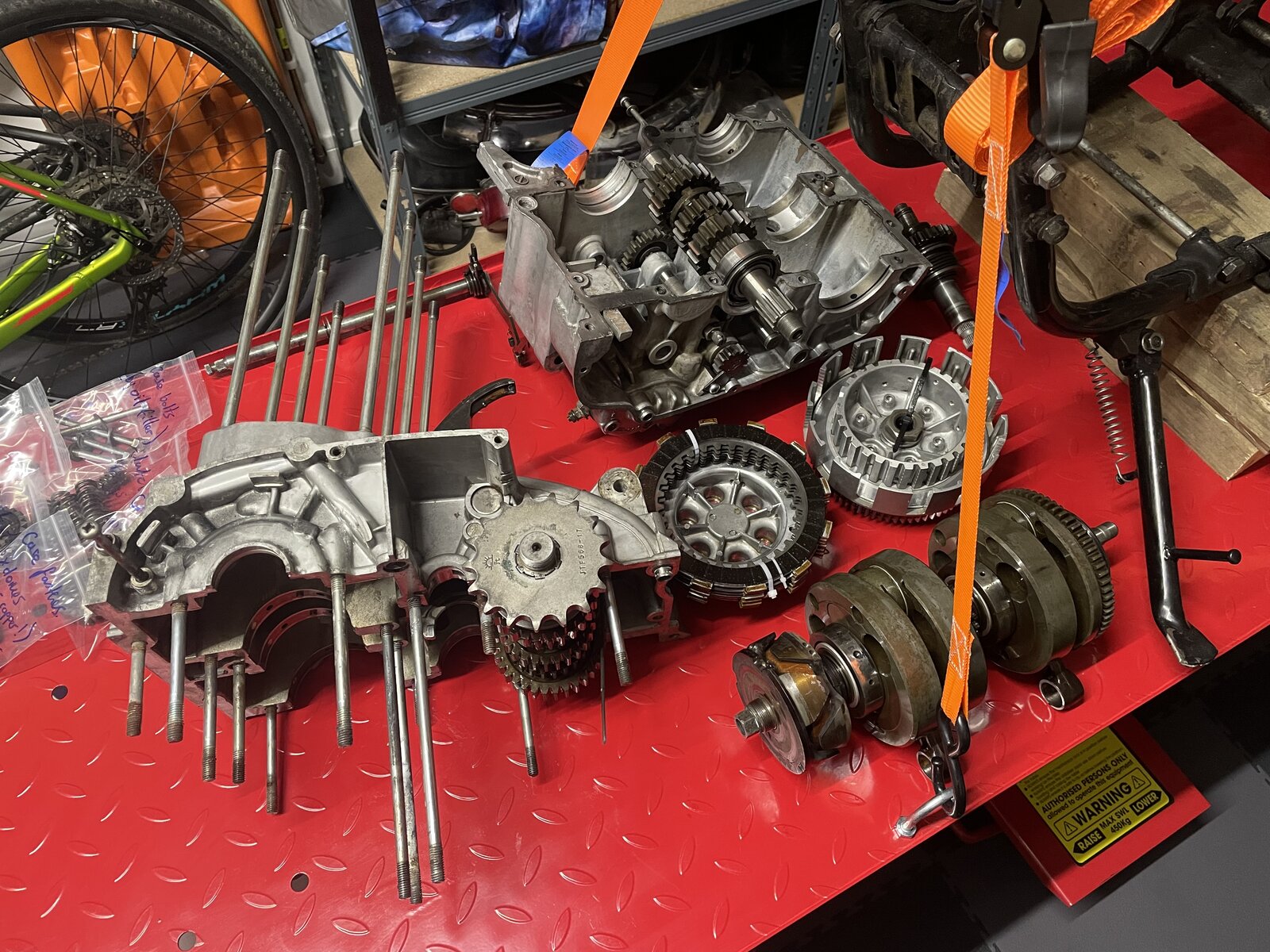

At my last update, I had started to tear the engine down. It's grown arms and legs, as expected. The (447) con-rod small ends are badly worn, and their heads are black. The motor felt, to me at least, quite good, in that it was free revving, sounded sweet, and pulled well. But then I suppose that's testament to this lump. I know this engine is known for keeping going, at least fairly well, even when in a bit of a grim state. It was in dire need of a rebuild.

Progress with the engine:

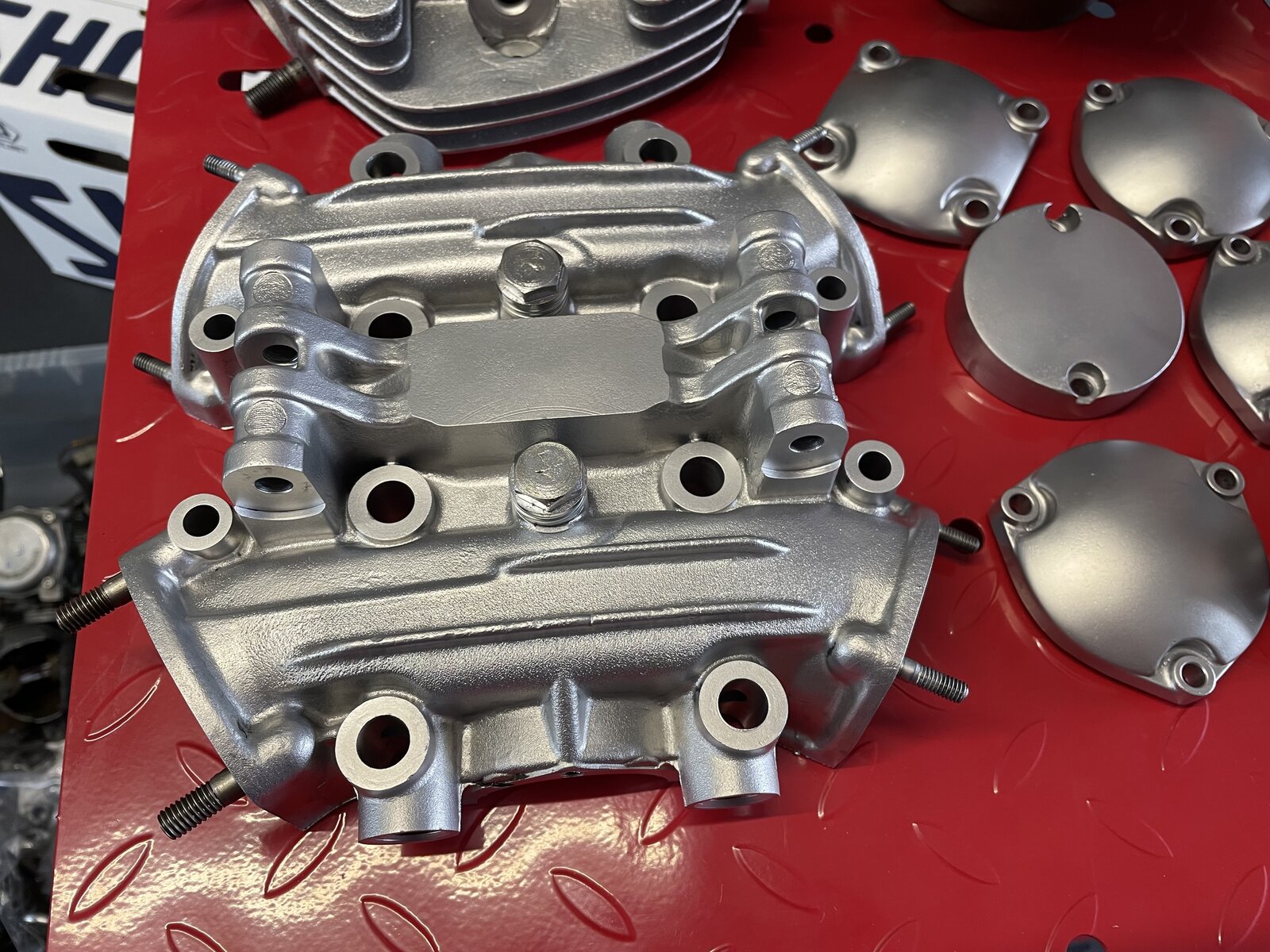

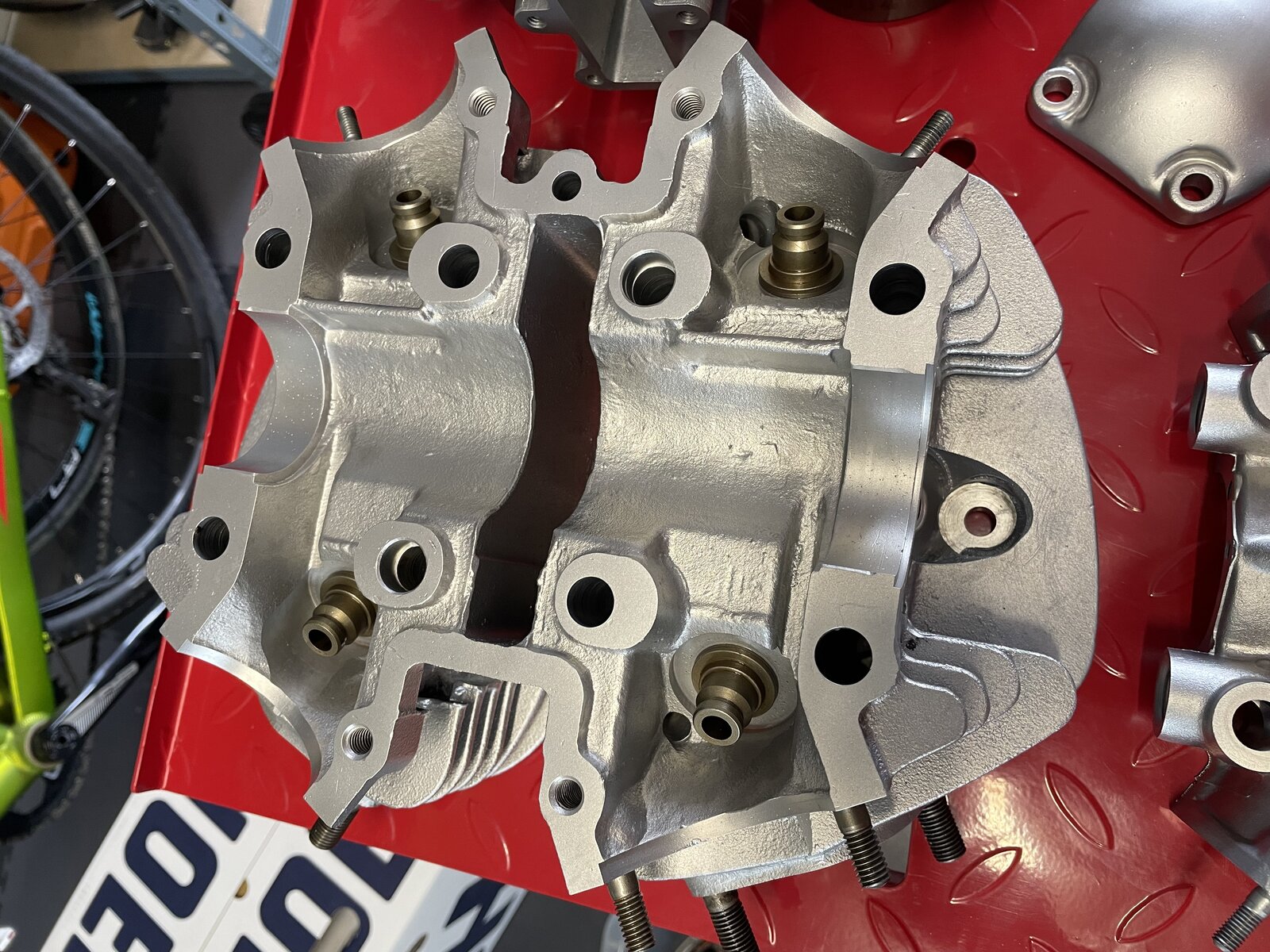

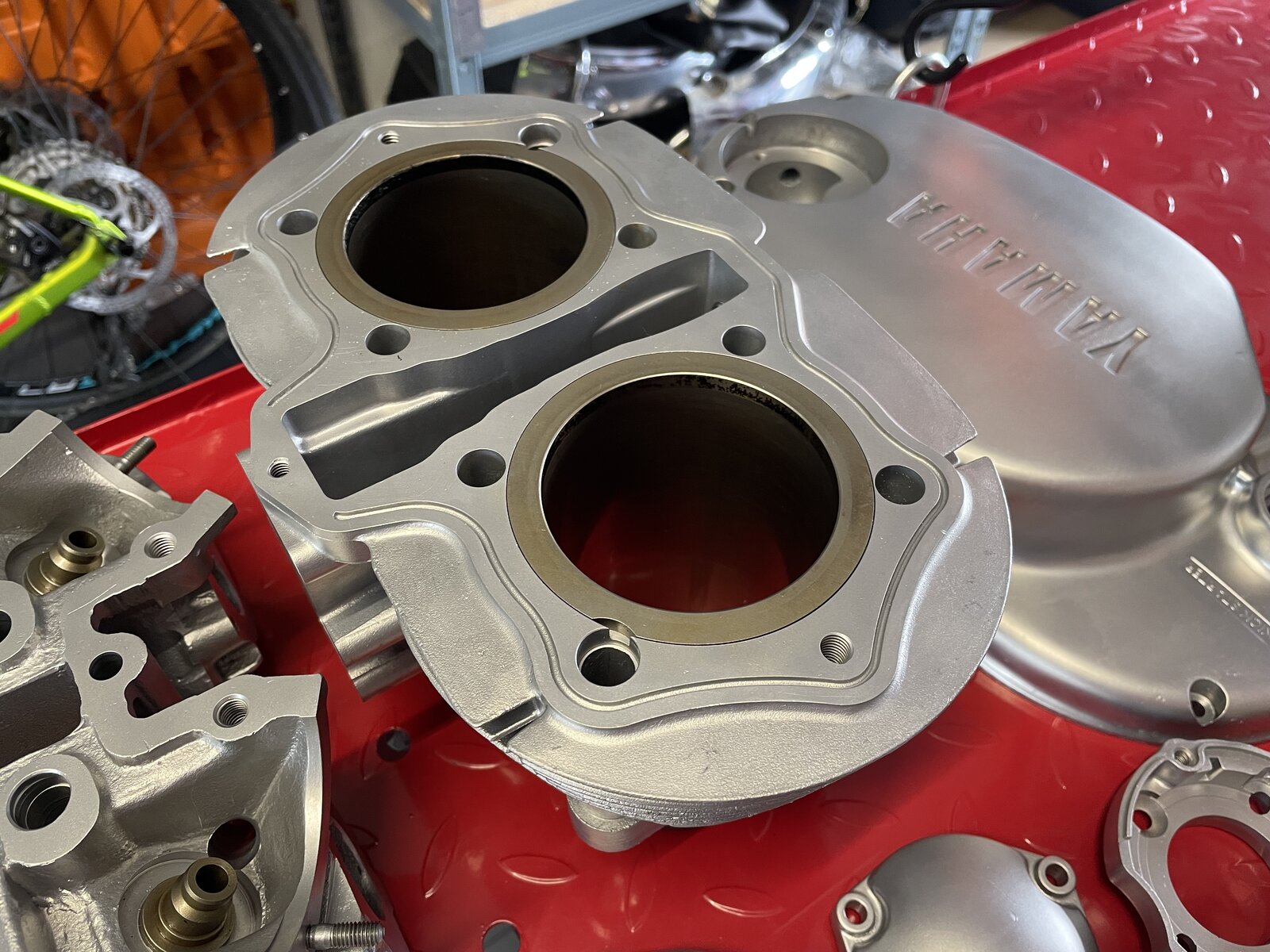

top end disassembled and inspected. Pistons not looking good, absolutely caked in carbon and with severe scoring all round the skirts. The rings were worn beyond spec, too. The cam and rocker arms look in good condition fortunately. This engine had standard .952 pistons and it has not been subject to any rebore in its lifetime as far as I can tell. Valves are in spec in their guides, but will be lapped and the seats recut while everything is apart.

Knowing that the worn small ends require a crank rebuild made me want to cry a little bit, given I hadn't budgeted for much engine work in my youthful naivety / misplaced optimism. So, with the help of this forum, and my two manuals, I set about disassembling the bottom end and splitting the cases. At first very daunting (this is my first foray into motor work), however I've taken my time, and been as organised and as careful as I possibly could've been.

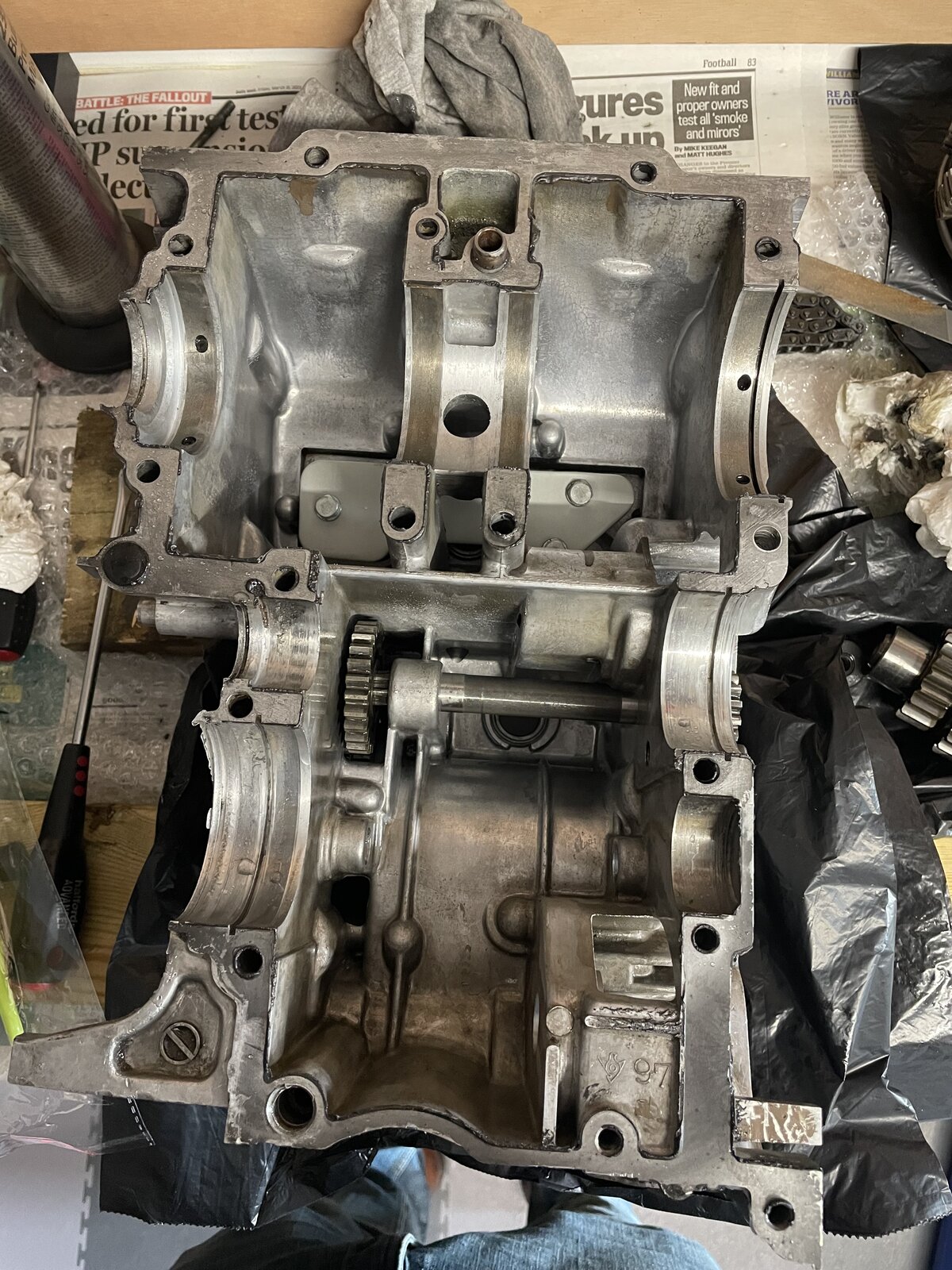

After prepping the bottom end for splitting, and definitely removing all 18 bolts / stud nuts(!), the cases were properly stuck together. After a lot of head scratching, heating, swearing, and losing skin from my knuckles, I managed to split them using the worlds smallest, simplest, puller. I used one M6 bolt and a couple of nuts wedged between the cases (wrapped in rags), very carefully opened the puller, and the cases prised apart locally just enough to allow me to work round their perimeter and get the job done. Satisfying.

I have had the top end vapour blasted. It looks great.

Headaches:

Someone has been at this motor previously, and the work done has been careless to put it kindly. I can't honestly remember all of the little things done badly, but most recently I discovered two of the dome nuts on the underside of the bottom case were missing their copper sealing washers (so that'll be where the leaking was coming from, then...), the head of one of the shoulder screws that retains the rear cam chain guide pivot arm is completely stripped and rounded out (haven't figured a solution for that one yet), and the case has been damaged around the countershaft sprocket oil seal and repaired with some sort of bodge. Predictably, that failed when I was removing the seal and so now I have to look into having that repaired. As I mentioned previously, the clutch push rod is badly bent, too. How that happened I have no idea.

Vapour blasted top end

Ready for painting the lettering

Clutch serviceable

Split...

Degreased with new strainer and sump plugs fitted

The green arrow indicates where the puller was placed to facilitate splitting the cases. Worked a treat.

Puller...

The offending rods

Phew

I've finished the front end now. Everything is rebuilt, powder coated, greased up, new needle roller headstock bearings etc. Looking good

Aside from the engine, I've got the frame completely bare, and I've started to de-tab it. I've also been playing around with CAD (cardboard aided design) to assist with making an electronics tray.

Far too deep currently, it'll be amended in due course.

So that's a bit of an update for anyone interested. In terms of next steps, I've got the swinging arm off being powder coated and I have new bronze bushings to install in that once it's back. The wheels are currently being rebuilt with stainless spokes, I'm looking forward to having them back and seeing them together with the new tyres and rejuvenated disc.

There's a local engine builder who is going to rebuild the crank for me with new rods and bearings, and I'm going to have the barrels rebored. It's all really rather expensive, isn't it? Who knew!

In terms of questions for the brains on here, can anyone advise why two of the screws that retain the camchain guide pivot arm are shouldered? Is there a a good reason not to replace those horrible screws with allen head set screws, for example?

Thanks for reading; all feedback, criticism, and piss taking welcome.

Cheers,

Mark

I've changed the thread title to make this my build thread as I couldn't be arsed starting a new thread to cover previous ground again. So, since I last wrote anything, here's what I've been up to. Plenty grins, and plenty gremlins along the way...

At my last update, I had started to tear the engine down. It's grown arms and legs, as expected. The (447) con-rod small ends are badly worn, and their heads are black. The motor felt, to me at least, quite good, in that it was free revving, sounded sweet, and pulled well. But then I suppose that's testament to this lump. I know this engine is known for keeping going, at least fairly well, even when in a bit of a grim state. It was in dire need of a rebuild.

Progress with the engine:

top end disassembled and inspected. Pistons not looking good, absolutely caked in carbon and with severe scoring all round the skirts. The rings were worn beyond spec, too. The cam and rocker arms look in good condition fortunately. This engine had standard .952 pistons and it has not been subject to any rebore in its lifetime as far as I can tell. Valves are in spec in their guides, but will be lapped and the seats recut while everything is apart.

Knowing that the worn small ends require a crank rebuild made me want to cry a little bit, given I hadn't budgeted for much engine work in my youthful naivety / misplaced optimism. So, with the help of this forum, and my two manuals, I set about disassembling the bottom end and splitting the cases. At first very daunting (this is my first foray into motor work), however I've taken my time, and been as organised and as careful as I possibly could've been.

After prepping the bottom end for splitting, and definitely removing all 18 bolts / stud nuts(!), the cases were properly stuck together. After a lot of head scratching, heating, swearing, and losing skin from my knuckles, I managed to split them using the worlds smallest, simplest, puller. I used one M6 bolt and a couple of nuts wedged between the cases (wrapped in rags), very carefully opened the puller, and the cases prised apart locally just enough to allow me to work round their perimeter and get the job done. Satisfying.

I have had the top end vapour blasted. It looks great.

Headaches:

Someone has been at this motor previously, and the work done has been careless to put it kindly. I can't honestly remember all of the little things done badly, but most recently I discovered two of the dome nuts on the underside of the bottom case were missing their copper sealing washers (so that'll be where the leaking was coming from, then...), the head of one of the shoulder screws that retains the rear cam chain guide pivot arm is completely stripped and rounded out (haven't figured a solution for that one yet), and the case has been damaged around the countershaft sprocket oil seal and repaired with some sort of bodge. Predictably, that failed when I was removing the seal and so now I have to look into having that repaired. As I mentioned previously, the clutch push rod is badly bent, too. How that happened I have no idea.

Vapour blasted top end

Ready for painting the lettering

Clutch serviceable

Split...

Degreased with new strainer and sump plugs fitted

The green arrow indicates where the puller was placed to facilitate splitting the cases. Worked a treat.

Puller...

The offending rods

Phew

I've finished the front end now. Everything is rebuilt, powder coated, greased up, new needle roller headstock bearings etc. Looking good

Aside from the engine, I've got the frame completely bare, and I've started to de-tab it. I've also been playing around with CAD (cardboard aided design) to assist with making an electronics tray.

Far too deep currently, it'll be amended in due course.

So that's a bit of an update for anyone interested. In terms of next steps, I've got the swinging arm off being powder coated and I have new bronze bushings to install in that once it's back. The wheels are currently being rebuilt with stainless spokes, I'm looking forward to having them back and seeing them together with the new tyres and rejuvenated disc.

There's a local engine builder who is going to rebuild the crank for me with new rods and bearings, and I'm going to have the barrels rebored. It's all really rather expensive, isn't it? Who knew!

In terms of questions for the brains on here, can anyone advise why two of the screws that retain the camchain guide pivot arm are shouldered? Is there a a good reason not to replace those horrible screws with allen head set screws, for example?

Thanks for reading; all feedback, criticism, and piss taking welcome.

Cheers,

Mark

Some good work going on here.

A calendar girl for sure when completed. Nice work.

It's all really rather expensive, isn't it? Who knew!

It sure is!

mrob24

XS650 Member

Thanks for your replies, gents! I appreciate them all. I'll keep the updates coming...