It’s starting to look pretty great Daniel! Can’t wait to see it come together!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

“Garage built, shed built”... stable built!

- Thread starter Bewarethemoon

- Start date

I've taken another photo in the daylight because the previous photo doesn't really show the tone correctly.

The Cerakote used is called crushed silver. I chose this over clear because the R6 top yoke (photos to come in good time) that I'm using has had some welding done to it and therefore couldn't be polished so I thought why not coat certain choice components in this shade.

Here are the exercise pieces from the fabrication course that I'm doing, nothing special (although to me they are) but all of the techniques that you need are utilised minus welding.

Daniel.

The Cerakote used is called crushed silver. I chose this over clear because the R6 top yoke (photos to come in good time) that I'm using has had some welding done to it and therefore couldn't be polished so I thought why not coat certain choice components in this shade.

Here are the exercise pieces from the fabrication course that I'm doing, nothing special (although to me they are) but all of the techniques that you need are utilised minus welding.

Daniel.

I think that was a good choice on the case finish. I'm anxious to see what you plan for side-cases' finish and the top-end. Those cases will set-off nicely a set of polished sidecases and a top-end in a slightly contrasting tone (perhaps).

I've taken another photo in the daylight because the previous photo doesn't really show the tone correctly.

View attachment 217736

The Cerakote used is called crushed silver. I chose this over clear because the R6 top yoke (photos to come in good time) that I'm using has had some welding done to it and therefore couldn't be polished so I thought why not coat certain choice components in this shade.

Here are the exercise pieces from the fabrication course that I'm doing, nothing special (although to me they are) but all of the techniques that you need are utilised minus welding.

View attachment 217737

Daniel.

Come on now, moon, aluminium must always be polished after the bending and beating. That is an unwritten law. There is a product called 'Glisten', which when used with adhesion promoter is supposed to stick pretty well to polished aluminium. I haven't tried it yet, but intend to. Cerakote is also supposed to be pretty good for polished aluminium, but it's only available as a kit with gun and other associated accessories in my part of the world, so I won't be trialing that.I've taken another photo in the daylight because the previous photo doesn't really show the tone correctly.

View attachment 217736

The Cerakote used is called crushed silver. I chose this over clear because the R6 top yoke (photos to come in good time) that I'm using has had some welding done to it and therefore couldn't be polished so I thought why not coat certain choice components in this shade.

Here are the exercise pieces from the fabrication course that I'm doing, nothing special (although to me they are) but all of the techniques that you need are utilised minus welding.

View attachment 217737

Daniel.

Attachments

Last edited:

I think that was a good choice on the case finish. I'm anxious to see what you plan for side-cases' finish and the top-end. Those cases will set-off nicely a set of polished sidecases and a top-end in a slightly contrasting tone (perhaps).

I’m go to polish the side casings & valve covers.

Then have the cylinder & head coated in the same crushed silver Cerakote. I’m also thinking of then mechanically removing the coating off the tips of the fins and then polish these surfaces.

Daniel.

Nice work Daniel! They look great!

Lucky Phil

XS650 Enthusiast

Hi DanielI’m go to polish the side casings & valve covers.

Then have the cylinder & head coated in the same crushed silver Cerakote. I’m also thinking of then mechanically removing the coating off the tips of the fins and then polish these surfaces.

Daniel.

Dig your build, just read the whole thread, I fully get your mind set, look forward to seeing the finnished bike.

Thanks

Phil

Quick little Sunday evening update.

I've been smoothing out the exterior weld on cowl MK1, I say MK1 because I've began to make another just for practice (the bug has well and truly bitten) I've also been trying to finalise how I'm going to produce the bottom section of the cowl, the piece that will be fixed to the frame.

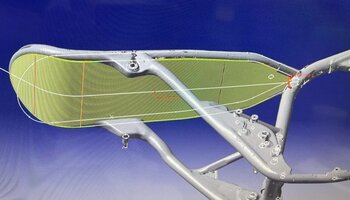

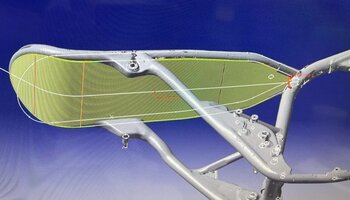

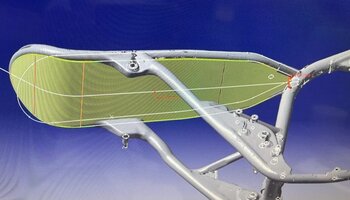

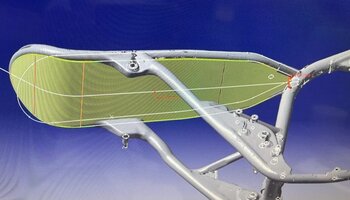

As I mentioned in another thread I've began planning out my undertray/base pan. I've seen this method done before and always loved it for how clean it looks. My plan is to TIG a 2mm thick plate between the tubing of the frame and then weld 'mounts' onto the top side of this to locate the battery & Motogadget M-Unit plus little guides for any cabling.

I'm in the unique position after having my frame digitally mapped to be able to have a rendering done to fit perfectly. I'm going to have the final piece made 4mm undersize to account for the thickness of material and then so after welding in place I can undergo the arduous task of blending it all into one seamless form.

On another note I've also had an exact reproduction of the factory rear sprocket made but in 7075 520 pitch.

Daniel.

I've been smoothing out the exterior weld on cowl MK1, I say MK1 because I've began to make another just for practice (the bug has well and truly bitten) I've also been trying to finalise how I'm going to produce the bottom section of the cowl, the piece that will be fixed to the frame.

As I mentioned in another thread I've began planning out my undertray/base pan. I've seen this method done before and always loved it for how clean it looks. My plan is to TIG a 2mm thick plate between the tubing of the frame and then weld 'mounts' onto the top side of this to locate the battery & Motogadget M-Unit plus little guides for any cabling.

I'm in the unique position after having my frame digitally mapped to be able to have a rendering done to fit perfectly. I'm going to have the final piece made 4mm undersize to account for the thickness of material and then so after welding in place I can undergo the arduous task of blending it all into one seamless form.

On another note I've also had an exact reproduction of the factory rear sprocket made but in 7075 520 pitch.

Daniel.

Digitally mapped? That's cheating! What's the fun in having a part that you don't spend hours filing and grinding on? Nice job.Quick little Sunday evening update.

I've been smoothing out the exterior weld on cowl MK1, I say MK1 because I've began to make another just for practice (the bug has well and truly bitten) I've also been trying to finalise how I'm going to produce the bottom section of the cowl, the piece that will be fixed to the frame.

As I mentioned in another thread I've began planning out my undertray/base pan. I've seen this method done before and always loved it for how clean it looks. My plan is to TIG a 2mm thick plate between the tubing of the frame and then weld 'mounts' onto the top side of this to locate the battery & Motogadget M-Unit plus little guides for any cabling.

I'm in the unique position after having my frame digitally mapped to be able to have a rendering done to fit perfectly. I'm going to have the final piece made 4mm undersize to account for the thickness of material and then so after welding in place I can undergo the arduous task of blending it all into one seamless form.

View attachment 218595

On another note I've also had an exact reproduction of the factory rear sprocket made but in 7075 520 pitch.

View attachment 218596View attachment 218597View attachment 218598

Daniel.

Digitally mapped? That's cheating! What's the fun in having a part that you don't spend hours filing and grinding on? Nice job.

I’ll still spend hours making it look like it grew there though if that’s any consolation?

Daniel.

I feel a little better now.I’ll still spend hours making it look like it grew there though if that’s any consolation?

Daniel.

I've mentioned it before but I'm using 5EB R6 yokes and a Cogniton Moto stem on my build.

Something I've struggled with for sometime is what to do in regards to the steering stops. I've seen on @Bjorn's thread that he was using a similar setup and noted his solution to the problem and appreciated his results but wanted to try something different (please read elaborate)

My first step was to remove the factory stops and compare their original location to @Bjorn's chosen local.

We then tapped the stops and drilled the yoke so a M3 bolt could act as a post to secure them prior to welding.

I wanted the yoke to look as close to the factory item as possible with the relocated stops, so after welding they were worked to resemble the original offering.

Heaps of work for something no one will ever notice!

Daniel.

Something I've struggled with for sometime is what to do in regards to the steering stops. I've seen on @Bjorn's thread that he was using a similar setup and noted his solution to the problem and appreciated his results but wanted to try something different (please read elaborate)

My first step was to remove the factory stops and compare their original location to @Bjorn's chosen local.

We then tapped the stops and drilled the yoke so a M3 bolt could act as a post to secure them prior to welding.

I wanted the yoke to look as close to the factory item as possible with the relocated stops, so after welding they were worked to resemble the original offering.

Heaps of work for something no one will ever notice!

Daniel.

Looks amazing! It’s the little details that set builds apartI've mentioned it before but I'm using 5EB R6 yokes and a Cogniton Moto stem on my build.

Something I've struggled with for sometime is what to do in regards to the steering stops. I've seen on @Bjorn's thread that he was using a similar setup and noted his solution to the problem and appreciated his results but wanted to try something different (please read elaborate)

My first step was to remove the factory stops and compare their original location to @Bjorn's chosen local.

View attachment 220120

View attachment 220122

We then tapped the stops and drilled the yoke so a M3 bolt could act as a post to secure them prior to welding.

View attachment 220123

View attachment 220124

I wanted the yoke to look as close to the factory item as possible with the relocated stops, so after welding they were worked to resemble the original offering.

View attachment 220126

View attachment 220127

Heaps of work for something no one will ever notice!

Daniel.

Looks amazing! It’s the little details that set builds apart

I agree wholeheartedly! The devil is most definitely in the detail and I love the challenege!

Daniel.

I have this frustrating ability to produce really nice welds where nobody will see them, even in hard to get places, then when it's out there for "God and everybody", It's "turds and toothpaste tubes". Perhaps a subliminal choke syndrome??

A couple of weeks back I referenced how I'd made further use of the digital mapping I've had undertaken on my frame.

This was then laser cut from 2mm steel and it turned up last week.

I set about offering it up and used Quickclamps to 'squeeze' it into place.

This allowed me to get a real good idea of what material if any needs to be removed to get a perfect fit. A little work with a Sharpie and a Carbide Burr on my Die Grinder and it should be spot on.

Daniel.

This was then laser cut from 2mm steel and it turned up last week.

I set about offering it up and used Quickclamps to 'squeeze' it into place.

This allowed me to get a real good idea of what material if any needs to be removed to get a perfect fit. A little work with a Sharpie and a Carbide Burr on my Die Grinder and it should be spot on.

Daniel.

Nice work! Although, I was expecting a “I decided to make a titanium frame” post haha

Nice work! Although, I was expecting a “I decided to make a titanium frame” post haha

You can bet that I've researched it and decided it's probably a non-starter.

Daniel.

Similar threads

- Replies

- 5

- Views

- 3K