Weekly Update

I did not get the time I was hoping for over the holiday weekend, but still have managed to get a couple of things knocked out.

I did get the jugs back from the machine shop. They were nice enough to run my freshly-enameled piece through an industrial parts washer… The enamel lost the fight, big time. Spent a good deal of time getting this piece stripped and repainted. In hindsight, I should have waited to paint until they were machined... Oh well, they are good to go now.

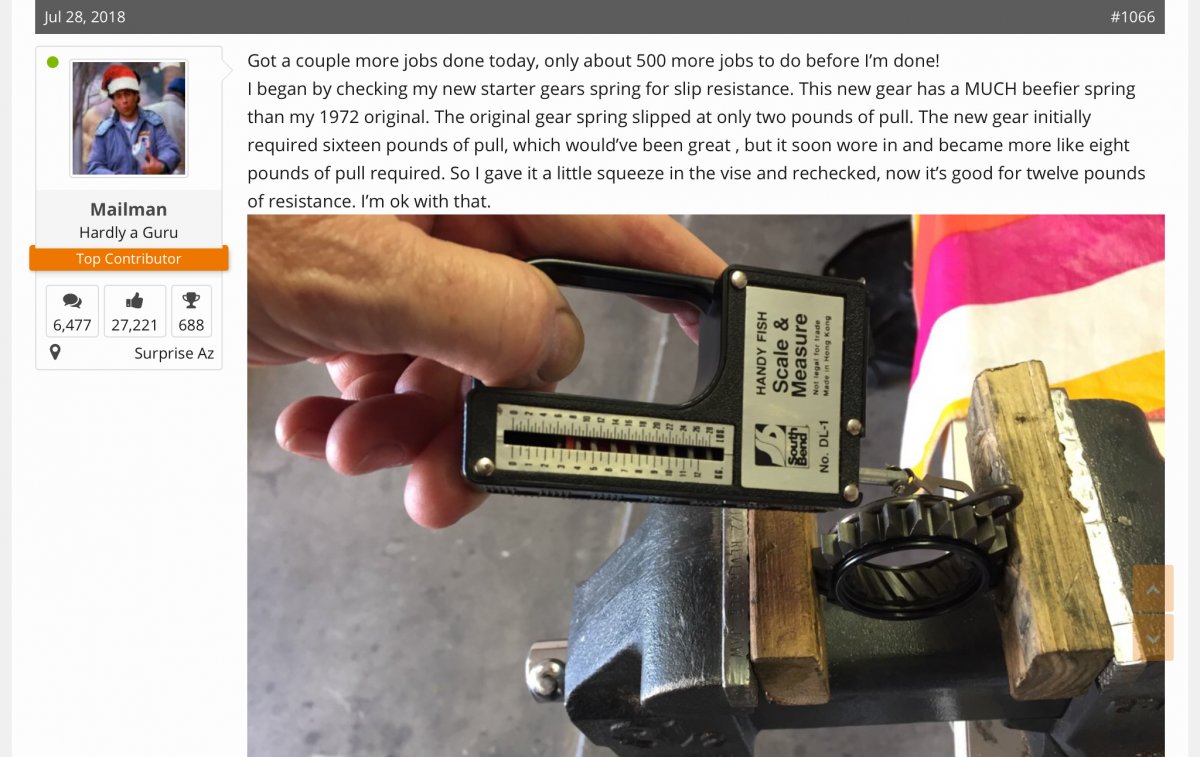

Per your last set of comments I got a fish scale and squeezed my #4 starter gear to about 8 pounds of pull. I finished the clutch assembly replacing the lock tab and springs. The clutch plates were surprisingly in good shape and as flat as could be. It is finally starting to look like an engine!

I installed the broken rotor and an old stator temporarily so I could set the timing. I think I will reuse the stator that is currently on the bike, as none of the ones lying around Dad’s shop are in very good shape and I know that one works.

I did run into an issue with the clutch pushrod. When I tried to install the left case, I found that the pushrod was protruding too far out and making contact with the worm gear before the cover made contact with the case. I backed the adjustment screw all the way out, but that didn’t help.

Any ideas? Could it have something to do with the one-piece pushrod I used? I am fairly sure that I have the worm gear together correctly. The gap is about an eighth of an inch…

Next step is to start on the top end assembly. This is getting a little tricky, as I have never disassembled this part of the engine. This extra engine came with the bike, but the top end was already totally disassembled. It also turns out that a couple of pieces were missing, such as the rear cam chain tensioner and the front cam chain guide. I ended up finding a rear tensioner in good shape around the shop and purchased a new front guide as they sound like they are the weak link in the system.

This guide by

@5twins was very helpful in matching together my hodgepodge of pieces.

This guide by

@Jim has proved to be invaluable for the top end so far. When I work on this project I have four texts in front of me; Haynes, Clymer, Pahl, and the service manual. Most of the time they are more or less in agreement, but when it comes to the top end they are all over the place. Each has a different approach and none of them address using an endless cam chain. I beat my head against a wall for 10 minutes trying to figure out how it went through the rear cam chain tensioner mount, only to discover that the mount has to be ground down and temporarily separated if you are using an endless chain!

I am optimistic that the rest of the assembly will go quickly once I get the jugs installed. Will keep you all posted!