Which do you think would be better 1mm over kibblewhite valves or 2mm over xv valves, if it was just down to size the answer would be obvious the kibblewhite are stainless so should have smoother flow across them against the heavier steel larger xv valves

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1mm or 2mm over valves

- Thread starter jay760

- Start date

Start with looking at your cams specs first. I have 1 mm OS Kibble-white IN & EX valves in a motor that is fully clearanced and yet to run.

With the 1 mm OS valves running a Shell #1 cam and timed straight up, the valve to valve clearance is borderline tight due to the shell #1's 100 deg lobe center. In my situation 2 mm OS valves would have caused clearance issues.

What cam are you running..?

EDIT - with the 2mm OS valves you may possibly need to look at throat cutting the bowl area..? However, from what I've read of others trials and tribulations its easy to go backwards when getting serious with bowl and port mods. My head has what I would call a simple street port - deschrouded combustion chambers, seat to bowl transitions and the smoothing and removal of all casting flash.

With the 1 mm OS valves running a Shell #1 cam and timed straight up, the valve to valve clearance is borderline tight due to the shell #1's 100 deg lobe center. In my situation 2 mm OS valves would have caused clearance issues.

What cam are you running..?

EDIT - with the 2mm OS valves you may possibly need to look at throat cutting the bowl area..? However, from what I've read of others trials and tribulations its easy to go backwards when getting serious with bowl and port mods. My head has what I would call a simple street port - deschrouded combustion chambers, seat to bowl transitions and the smoothing and removal of all casting flash.

Your not going to see a flow improvement with the KW valve because it's stainless steel.Take the XV valves and cut'em down to stock dimensions for two reasons, a thicker valve margin will have less flow resistance ,

you can hear this on a flow bench. The xv exhaust valve have a better tulip shape than KW for better flow

and slightly aiding in reducing port volume. When you cut the xv EV ,radius the bottom valve margin to deduce resistance,which will speed up the exhaust pulse flow around the valve margin and head of valve.

Oversized valves with oversized ports are a bad combination where port velocity would drop off once the valve breaks from the seat. You want small ports when using OSV to keep port velocity up where it belongs

so it doesn't drop off when the valve breaks from the seat and the engine will develop a broader power range through out the RPM.

Those KW valve aren't as good as you think they are,especially the exhaust. The faces are to soft and will sink over time. Had a set in my BMW ,never again

you can hear this on a flow bench. The xv exhaust valve have a better tulip shape than KW for better flow

and slightly aiding in reducing port volume. When you cut the xv EV ,radius the bottom valve margin to deduce resistance,which will speed up the exhaust pulse flow around the valve margin and head of valve.

Oversized valves with oversized ports are a bad combination where port velocity would drop off once the valve breaks from the seat. You want small ports when using OSV to keep port velocity up where it belongs

so it doesn't drop off when the valve breaks from the seat and the engine will develop a broader power range through out the RPM.

Those KW valve aren't as good as you think they are,especially the exhaust. The faces are to soft and will sink over time. Had a set in my BMW ,never again

Last edited:

Ebay vendor SMW70ss (Schumann Motor Works) offers in-house produced forged stainless performance and oversized valves for the XS650. No listings at the moment, until he makes another batch. He claims that he can do custom sizes on request.

https://rover.ebay.com/rover/0/0/0?mpre=https://www.ebay.com/ulk/itm/232496722937

https://rover.ebay.com/rover/0/0/0?mpre=https://www.ebay.com/ulk/itm/232496722937

Jack should have some fun with this.

1975, I had rebuilt the engine several times for various mods and such, like factory 750 kit, custom grind cam, ...etc. It was already a strong performer, but something just kept bugging me. Them tiny exhaust valves. At the time, I was of the mindset that the engine was originally designed to be a 750cc, but downsized and detuned for 650cc (per the reps I was communicating with). So, peering at the combustion chambers and valves, then comparing them to other performance heads, it certainly looked like the exhaust valves were shrunk in keeping with the downsized design.

An older time, different mindsets. Started looking into In/Exh valve diameter ratios. A 38mm (vs stock 35mm) exh valve would regain that valve diameter ratio.

So, that's what I did, made some 38mm exh valves. Non-tulip (or barely so). Kept the intakes stock at 41mm. Even with my wide lobe center cam, valve clearance at overlap was terrifyingly close.

Seat-of-the-pants dyno said big improvement. Plus, severe reversion at 4,000 rpm. Which was a good sign. Just took a long time with exh mods and tuning to get that reversion tolerable...

1975, I had rebuilt the engine several times for various mods and such, like factory 750 kit, custom grind cam, ...etc. It was already a strong performer, but something just kept bugging me. Them tiny exhaust valves. At the time, I was of the mindset that the engine was originally designed to be a 750cc, but downsized and detuned for 650cc (per the reps I was communicating with). So, peering at the combustion chambers and valves, then comparing them to other performance heads, it certainly looked like the exhaust valves were shrunk in keeping with the downsized design.

An older time, different mindsets. Started looking into In/Exh valve diameter ratios. A 38mm (vs stock 35mm) exh valve would regain that valve diameter ratio.

So, that's what I did, made some 38mm exh valves. Non-tulip (or barely so). Kept the intakes stock at 41mm. Even with my wide lobe center cam, valve clearance at overlap was terrifyingly close.

Seat-of-the-pants dyno said big improvement. Plus, severe reversion at 4,000 rpm. Which was a good sign. Just took a long time with exh mods and tuning to get that reversion tolerable...

I wonder if that's why xs laden https://www.xs-laden.de only seem to stock 3mm over exhaust and 2mm over inlet valves.

I am only interested in high revs as the only time the bike runs at normal speeds is on the way back to the pits other than that it's flat out.

I run an unknown cam high lift long duration, with JE pistons, also has 1mm over kibblewhite valves, I was about to change to the xv750 valves which I have then I read somewhere about how the flow increased on the stainless valves and then someone said about the weight of the xv valves.

I am only interested in high revs as the only time the bike runs at normal speeds is on the way back to the pits other than that it's flat out.

I run an unknown cam high lift long duration, with JE pistons, also has 1mm over kibblewhite valves, I was about to change to the xv750 valves which I have then I read somewhere about how the flow increased on the stainless valves and then someone said about the weight of the xv valves.

Hey, thanx for that link! Maybe I can forego having to make another set of valves...

...I am only interested in high revs ...

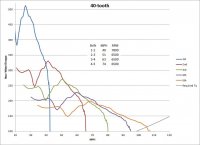

More oldschool scavenging rambling stuff.

That reversion can be a tuning tool. The worse it is at mid-rpm, the better at high rpm, where it "comes on the pipe". Have a look at mrriggs torque curves,

From this thread:

http://www.xs650.com/threads/gearing-for-your-best-performance.36605/

Note the severe torque drops around 3,500 rpm, followed by the impressive peaks around 5,000 rpm. Factory mufflers flatten those torque curves by mitigating the reversion pulses, using what folks call "back pressure" (not my favorite term). However, by observing and targeting the torque drop, you can position the torque spike...

What does that mean?deschrouded combustion chambers

What has to be done to use oversize valves? What does the head need. New or recut valve seats?

Liftedzuki

XS650 Addict

Hudriwudri

XS650 Addict

Hi there,

I allow myself to answer as I do quite a lot of such headwork (although mostly on singles tt/xt etc).

See, if you put in vastly bigger valves in particular on the intake side in a somewhat space restricted confined combustion chamber, you can run into the phenomena that although you use bigger valves that you end up with less flow as the combustion chamber walls are to near to allow thorough breathing.

Considering now that the xs chambers can still imho be regarded as pretty old school (a hint like triumph) you are limited in which size valve you can stuff in in relation to diminishing returns and danger of valve collision.

E.g. imagine putting a 45 mm (could be actually with some reasonable surgery done) valve into the original head and see how much space you still have to the chamber walls and how much effort the engine will need to suck mixture through in comparison to before.

One usually can go in brief 3 ways:

1. Go with a reasonable size increment and watch that the increment stays within the duration of the cam and relief chamber by means of seat relief cutter for valve seat tool/stones etc.

2. Go with a bigger Increment and watch that valves do not collide during overlap and relief the chambers by milling machine or more heavy duty means

3. Go a lot bigger and reangle valves according to overlap necessities and port intake according to velocity profile needed.

Reshape combustion chamber according to what the flow characteristics and numbers dictate you.

Mostly that would imho only needed on 1-2 cams of which I could think of as otherwise one would get too much flow area at too much of semi low lift duration.

Hope that my short rantings made it a hint clearer.

Kind regards

Christian

PS: i do not understand what or why one needs a batch of xv valves done?

The size is pretty much the same and at most one needs to shim the springs according to needed retainer key height?

For chamber reliefing i'd reckon any machinist with porsche or Hemi experience or some valid capacity of reasoning/experience should be able to do such a seat job without any troubles?

I allow myself to answer as I do quite a lot of such headwork (although mostly on singles tt/xt etc).

See, if you put in vastly bigger valves in particular on the intake side in a somewhat space restricted confined combustion chamber, you can run into the phenomena that although you use bigger valves that you end up with less flow as the combustion chamber walls are to near to allow thorough breathing.

Considering now that the xs chambers can still imho be regarded as pretty old school (a hint like triumph) you are limited in which size valve you can stuff in in relation to diminishing returns and danger of valve collision.

E.g. imagine putting a 45 mm (could be actually with some reasonable surgery done) valve into the original head and see how much space you still have to the chamber walls and how much effort the engine will need to suck mixture through in comparison to before.

One usually can go in brief 3 ways:

1. Go with a reasonable size increment and watch that the increment stays within the duration of the cam and relief chamber by means of seat relief cutter for valve seat tool/stones etc.

2. Go with a bigger Increment and watch that valves do not collide during overlap and relief the chambers by milling machine or more heavy duty means

3. Go a lot bigger and reangle valves according to overlap necessities and port intake according to velocity profile needed.

Reshape combustion chamber according to what the flow characteristics and numbers dictate you.

Mostly that would imho only needed on 1-2 cams of which I could think of as otherwise one would get too much flow area at too much of semi low lift duration.

Hope that my short rantings made it a hint clearer.

Kind regards

Christian

PS: i do not understand what or why one needs a batch of xv valves done?

The size is pretty much the same and at most one needs to shim the springs according to needed retainer key height?

For chamber reliefing i'd reckon any machinist with porsche or Hemi experience or some valid capacity of reasoning/experience should be able to do such a seat job without any troubles?

Last edited:

Hudriwudri

XS650 Addict

@joebgd

Well not knowing your camshaft, but assuming the original profile i assume it should be very doable.

Try to have, if possible, somebody with some experience do the seats, as one would have to most likely also enlarge the seat throat area and while being there relief a hint the seat area at least on the intake.

Everything easily doable but one should know what one is doing.

Kind regards

Christian

Well not knowing your camshaft, but assuming the original profile i assume it should be very doable.

Try to have, if possible, somebody with some experience do the seats, as one would have to most likely also enlarge the seat throat area and while being there relief a hint the seat area at least on the intake.

Everything easily doable but one should know what one is doing.

Kind regards

Christian

Liftedzuki

XS650 Addict

Hi there,

I allow myself to answer as I do quite a lot of such headwork (although mostly on singles tt/xt etc).

See, if you put in vastly bigger valves in particular on the intake side in a somewhat space restricted confined combustion chamber, you can run into the phenomena that although you use bigger valves that you end up with less flow as the combustion chamber walls are to near to allow thorough breathing.

Considering now that the xs chambers can still imho be regarded as pretty old school (a hint like triumph) you are limited in which size valve you can stuff in in relation to diminishing returns and danger of valve collision.

E.g. imagine putting a 45 mm (could be actually with some reasonable surgery done) valve into the original head and see how much space you still have to the chamber walls and how much effort the engine will need to suck mixture through in comparison to before.

One usually can go in brief 3 ways:

1. Go with a reasonable size increment and watch that the increment stays within the duration of the cam and relief chamber by means of seat relief cutter for valve seat tool/stones etc.

2. Go with a bigger Increment and watch that valves do not collide during overlap and relief the chambers by milling machine or more heavy duty means

3. Go a lot bigger and reangle valves according to overlap necessities and port intake according to velocity profile needed.

Reshape combustion chamber according to what the flow characteristics and numbers dictate you.

Mostly that would imho only needed on 1-2 cams of which I could think of as otherwise one would get too much flow area at too much of semi low lift duration.

Hope that my short rantings made it a hint clearer.

Kind regards

Christian

PS: i do not understand what or why one needs a batch of xv valves done?

The size is pretty much the same and at most one needs to shim the springs according to needed retainer key height?

For chamber reliefing i'd reckon any machinist with porsche or Hemi experience or some valid capacity of reasoning/experience should be able to do such a seat job without any troubles?

The valves need cut down (2mm too large).

Is that basic knowledge?

I have a good machinist but he said he won't grind? Cut? motorcycle valves, he said they're unserviceable

(I wanted my oem valves cut, I will later pull the head for a professionally ported head).

He wanted me to buy new stock valves and then he will cut the seats. He does a great job on the cylinders I've had bored out.

Hudriwudri

XS650 Addict

@Liftedzuki

You're machinist is for what I would know right.

Depending on what type of valves are being used one can only grind away so much before getting below the hardened/tempered sealing area of the valve.

The thing that I don't understand is why did you buy xv valves in 2mm oversize if you then wanto to cut em down to stock size?

At that point you could have bought stock size valves, or am I missing something?

Kind regards

Christian

You're machinist is for what I would know right.

Depending on what type of valves are being used one can only grind away so much before getting below the hardened/tempered sealing area of the valve.

The thing that I don't understand is why did you buy xv valves in 2mm oversize if you then wanto to cut em down to stock size?

At that point you could have bought stock size valves, or am I missing something?

Kind regards

Christian

I think @Liftedzuki is speaking of length not diameter.................

Hudriwudri

XS650 Addict

@gggGary

Ah ok well that changes things a lil of course.

Well I myself don't have any xv valves here on hand, but given the measurements at the beginning of the topic I could almost not imagine that length would differ that much that one could not get by with different shims under the springs.

If worse comes to worse, one could shorten the valves and (perhaps with need to recut keeper groove on lathe) either use lash caps, or the half ball adjuster screws from kedo for the xt500 in order to keep surface pressures low and avoid grooving even in non hardened surface

Or else renitride the valve stems after cutting to length (although would be careful with race spring pressures for exceedung point pressures of the hertz type).

Kind regards

Christian

Ah ok well that changes things a lil of course.

Well I myself don't have any xv valves here on hand, but given the measurements at the beginning of the topic I could almost not imagine that length would differ that much that one could not get by with different shims under the springs.

If worse comes to worse, one could shorten the valves and (perhaps with need to recut keeper groove on lathe) either use lash caps, or the half ball adjuster screws from kedo for the xt500 in order to keep surface pressures low and avoid grooving even in non hardened surface

Or else renitride the valve stems after cutting to length (although would be careful with race spring pressures for exceedung point pressures of the hertz type).

Kind regards

Christian

Liftedzuki

XS650 Addict

I was under the impression from Jack's post, people are cutting the XV valves to stock Xs650 valve size since they are 2mm larger on both intake and exhaust.

Length would be unchanged due to being nearly identical.

Length would be unchanged due to being nearly identical.

Liftedzuki

XS650 Addict

@Liftedzuki

You're machinist is for what I would know right.

Depending on what type of valves are being used one can only grind away so much before getting below the hardened/tempered sealing area of the valve.

The thing that I don't understand is why did you buy xv valves in 2mm oversize if you then wanto to cut em down to stock size?

At that point you could have bought stock size valves, or am I missing something?

Kind regards

Christian

See Jack's post way above. I've read from a few people cut down they have a better shape than any other option for us xs650 owners.

I would love oem yamaha xs650 valves, but discontinued.