Today I am installing MikesXS Non-vacuum petcocks on my single-petcock '83 and '80 Specials.

Forgive me if this is all repetitive, but I thought that at least some aspects of the install might be helpful to somebody.

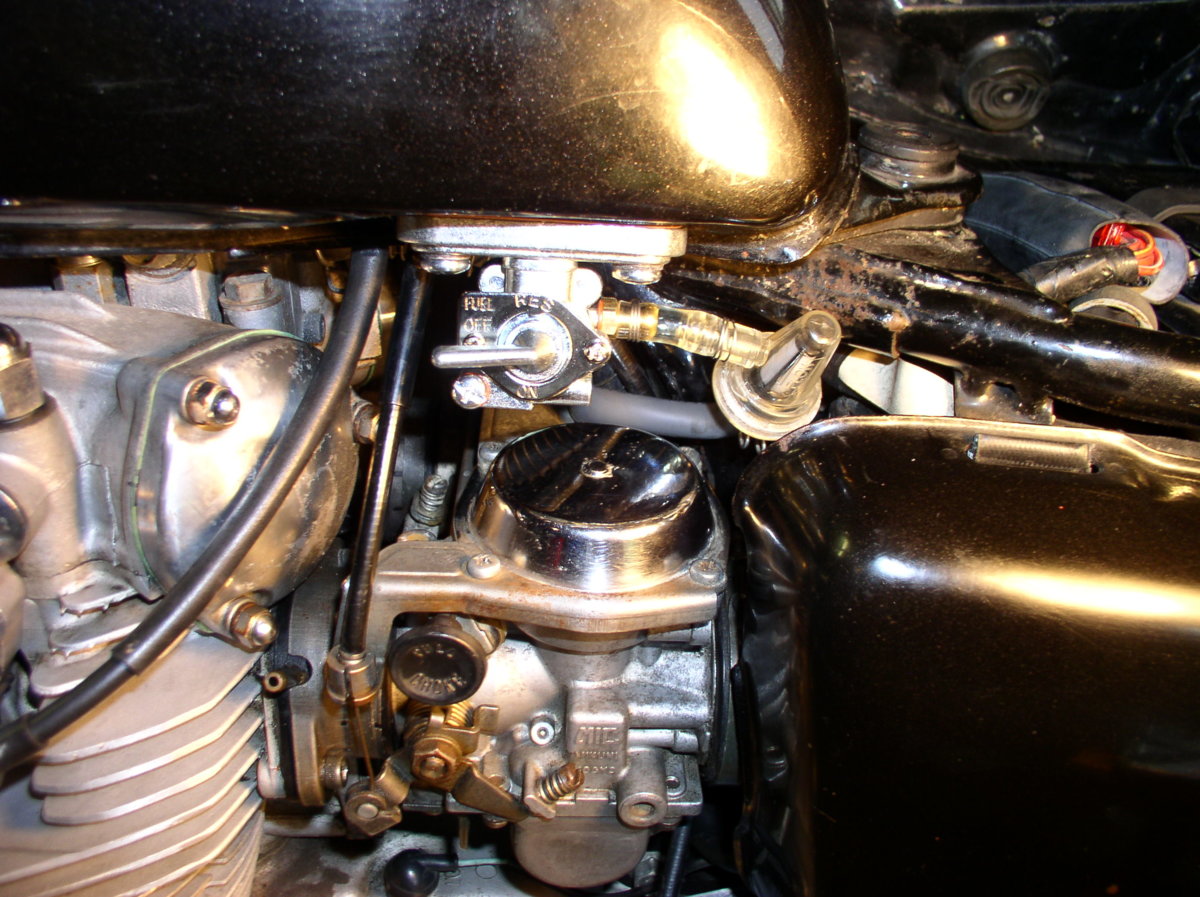

So, here is the unit on my '80, which works fine, but I'd rather go Non-vacuum for the obvious reasons.

As you can see, the ideal is to aim the gas with a 90 degree fitting towards the center of the bike. The new petcock comes with straight and 90 degree fittings.

However, when I tightened one of the 90 fittings all the way in, it was angled at about 2:00, not at all ideal:

This angle is best, but some sort of modification would need to be done:

The other Mikes' petcock tightened to an angle that was worse, 7:00. (not pictured)

However, adding extra filtration is a good thing, and a 90 degree filter attached to the straight petcock fitting (provided) will fit into the chassis fairly well:

For accessible connections, I use stainless safety wire, which gives me peace of mind.

No need to drain the gas if you have 1/3 of a tank or less, just prop it up with a gallon oil bottle:

Clean the tank connection surface,

and use new sealing washers and screws. Dirt cheap at Mikes:

The sealing washers go onto the screws VERY tight. I grab them with my fingers:

No need to use any sealing goop, in my experience.

Installed:

The filter tucks in fairly well. As you can see, I wrap the safety wire 3 times, and twist. Not too tight, tho.

Hope this is useful to someone.

Forgive me if this is all repetitive, but I thought that at least some aspects of the install might be helpful to somebody.

So, here is the unit on my '80, which works fine, but I'd rather go Non-vacuum for the obvious reasons.

As you can see, the ideal is to aim the gas with a 90 degree fitting towards the center of the bike. The new petcock comes with straight and 90 degree fittings.

However, when I tightened one of the 90 fittings all the way in, it was angled at about 2:00, not at all ideal:

This angle is best, but some sort of modification would need to be done:

The other Mikes' petcock tightened to an angle that was worse, 7:00. (not pictured)

However, adding extra filtration is a good thing, and a 90 degree filter attached to the straight petcock fitting (provided) will fit into the chassis fairly well:

For accessible connections, I use stainless safety wire, which gives me peace of mind.

No need to drain the gas if you have 1/3 of a tank or less, just prop it up with a gallon oil bottle:

Clean the tank connection surface,

and use new sealing washers and screws. Dirt cheap at Mikes:

The sealing washers go onto the screws VERY tight. I grab them with my fingers:

No need to use any sealing goop, in my experience.

Installed:

The filter tucks in fairly well. As you can see, I wrap the safety wire 3 times, and twist. Not too tight, tho.

Hope this is useful to someone.

Last edited: