I just ground my own 55 degree threading tool out of a HSS blank when I was building my Triumph and working on guns that had Whitworth threads. I'll look around and see if I still have it.I guess the only possible difference would be included thread angle, 60° Unified vs. 55° Whitworth

Since I'm cutting my own I'll be using 60° threading tool and replacement axle nuts are available from the local auto parts store for a few bucks each.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'68 BSA Victor Build..... Bloody 'el mate... You 'effin daft or sommat?!?

- Thread starter Jim

- Start date

Into the jaws of the Orange Beast....

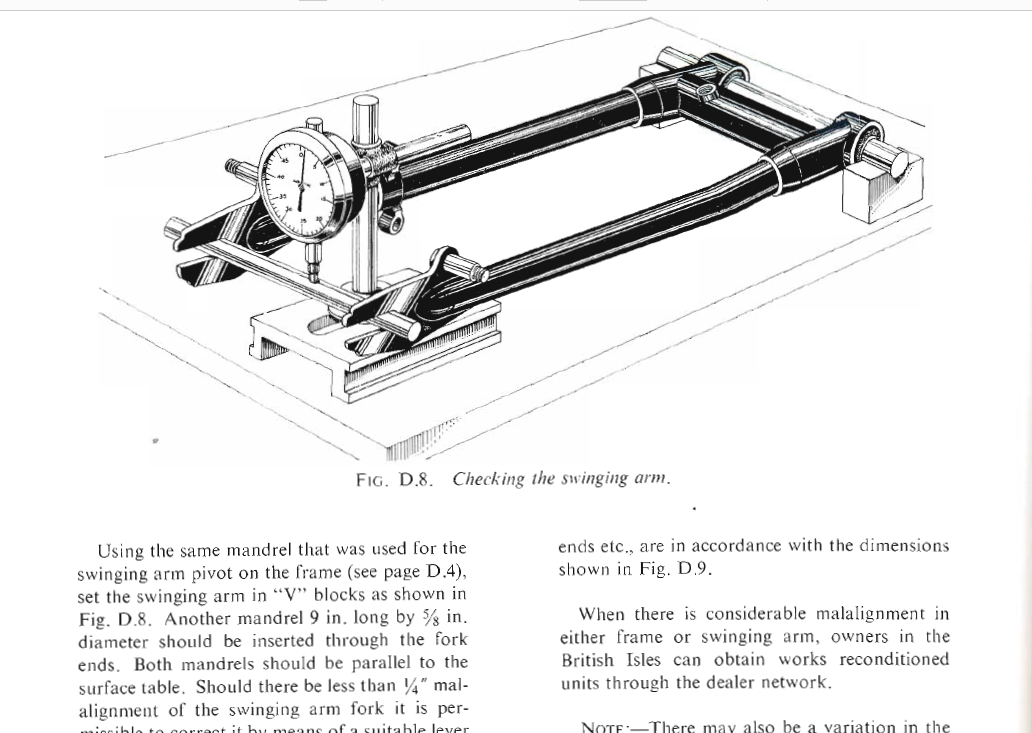

Oddly enough, the manual doesn't give a tolerance for swingarm misalignment. All it says is if the bend is less than 1/4", you can bend it back into shape yourself. If it's past that, return it to a dealer for straightening. Indeed....

Not having a dealer close by... ....

....

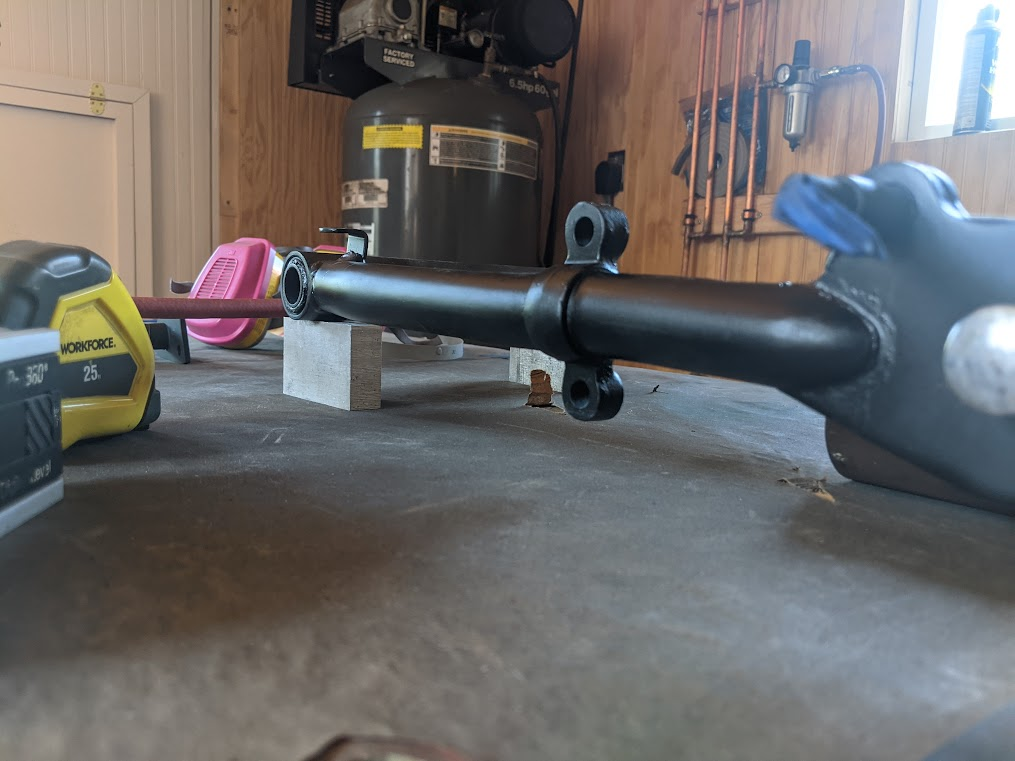

I didn't measure before hand. As a guess I'd say between 1/4 and 1/2" at the rear spindle saddles. Set it up in the beast and slowly bent it back. I was somewhat surprised to see very little spring back as I checked it along the way. A sign of pretty soft tubing.

...and here we are.

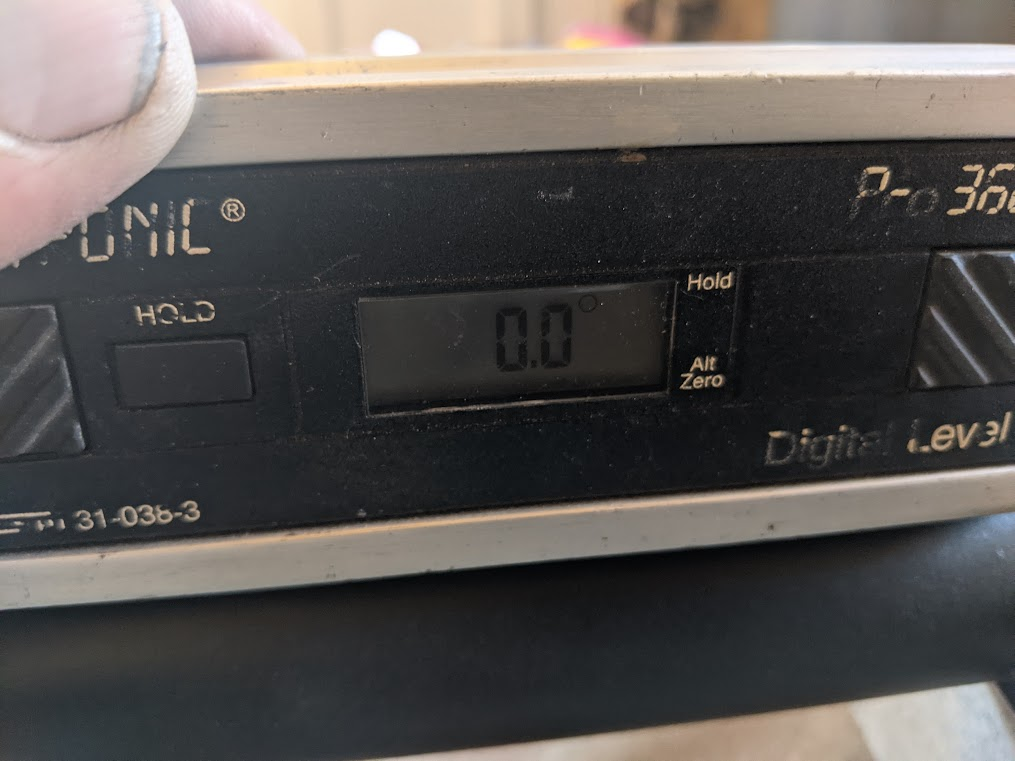

Rather than measure true misalignment in inches, I measured degrees... which is easier to set up for. Set my level on the cross (pivot) tube and zeroed.

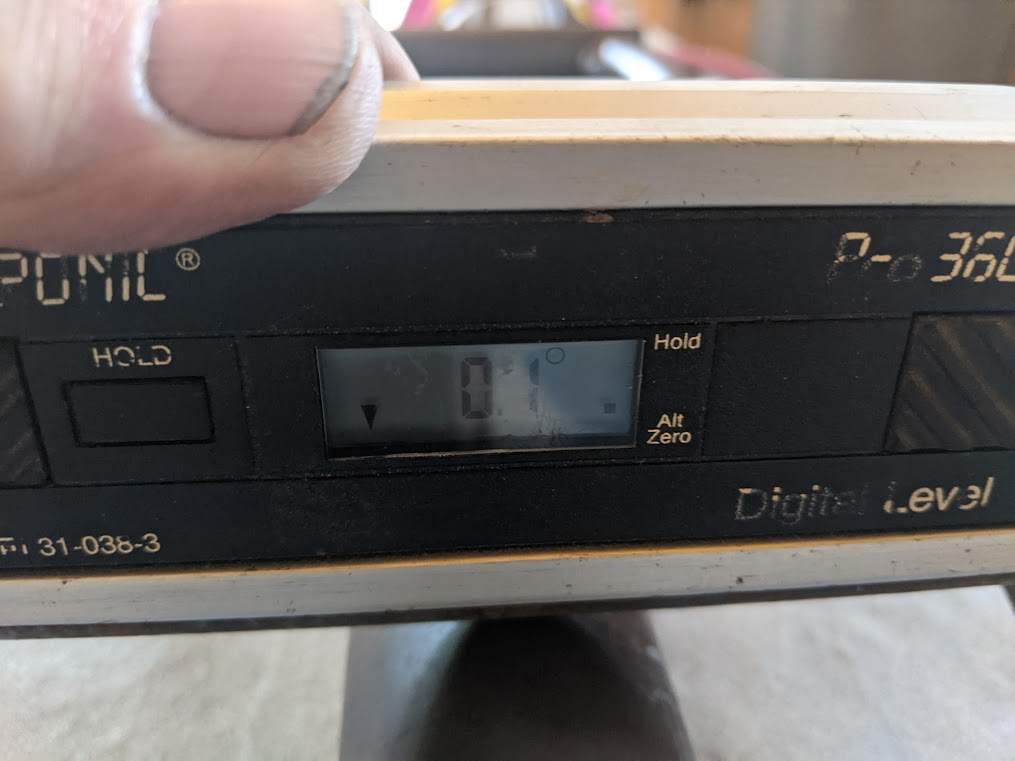

Set it on the rear axle and it's off 0.1°... a tenth of a degree.

So, a little math.... Between the saddles is 7.875". We'll call that our radius. Gives us a circumference of 49.48". Divide that into 360° for a full circle and we get 0.137" per degree.... or 0.0137" per tenth of a degree. So, my misalignment is about the gap of a set of points.... I think I can live with that.

Oddly enough, the manual doesn't give a tolerance for swingarm misalignment. All it says is if the bend is less than 1/4", you can bend it back into shape yourself. If it's past that, return it to a dealer for straightening. Indeed....

Not having a dealer close by...

....

....I didn't measure before hand. As a guess I'd say between 1/4 and 1/2" at the rear spindle saddles. Set it up in the beast and slowly bent it back. I was somewhat surprised to see very little spring back as I checked it along the way. A sign of pretty soft tubing.

...and here we are.

Rather than measure true misalignment in inches, I measured degrees... which is easier to set up for. Set my level on the cross (pivot) tube and zeroed.

Set it on the rear axle and it's off 0.1°... a tenth of a degree.

So, a little math.... Between the saddles is 7.875". We'll call that our radius. Gives us a circumference of 49.48". Divide that into 360° for a full circle and we get 0.137" per degree.... or 0.0137" per tenth of a degree. So, my misalignment is about the gap of a set of points.... I think I can live with that.

Less than 14 thou twist - possibly better than BSA built it?Much better than BSA painted it.

No, let's be charitable to BSA and say probably within factory tolerance.

Not on a weekday, that's for sure.Less than 14 thou twist - possibly better than BSA built it?

No, let's be charitable to BSA and say probably within factory tolerance.

Nice work! Hardly even scuffed the paint!  Now take it easy coming off the jumps next time!

Now take it easy coming off the jumps next time!

Nice fix Jim!

Probably why it bent in the 1st place.... A sign of pretty soft tubing.

Whatcha' gonna' do when your Centari stash is used up? FWIW, Nason Ful-Cryl ain't half bad. Nason Ful-Thane is excellent, but costs more and dries really slow.Frame is done! Phew.....

I shot 2 coats of Centari Negro Intenso (love that name)

Mixed up 8oz of clear and cut it pretty heavy with a slow (90°) reducer... about 12oz total. I shot that 'till it was gone. Didn't count coats. As a guess, prolly 3 or 4.

Very happy with it.

View attachment 215996

View attachment 215998

View attachment 215999

View attachment 216000

I used some hooks and wire to make it easier to shoot underneath it. Hooks are on the East and West walls so it made it pretty easy to get full coverage all around.

View attachment 216001

I'll let that cure up for a week or two, then bring it up to the garage and start the reassembly.

Actually, used up my stash on the SG. It's still available though. Bought some more through these guys. It's the real deal. Even smells the same.Whatcha' gonna' do when your Centari stash is used up? FWIW, Nason Ful-Cryl ain't half bad. Nason Ful-Thane is excellent, but costs more and dries really slow.

https://www.johnsonautobodysupply.com/DuPont-Centari-Pitch-Black-99A-(Quart).html

....and we're back on track...

2 coats Centari Negro Intenso and 2 coats clear. One of the aluminum blocks I used to press the swingarm back straight left a dent in the tube. For just an instant my OCD flared up and I considered filling it in.... but nah... it's a battle scar.

2 coats Centari Negro Intenso and 2 coats clear. One of the aluminum blocks I used to press the swingarm back straight left a dent in the tube. For just an instant my OCD flared up and I considered filling it in.... but nah... it's a battle scar.

Chicks dig scars

Good to know.Actually, used up my stash on the SG. It's still available though. Bought some more through these guys. It's the real deal. Even smells the same.

https://www.johnsonautobodysupply.com/DuPont-Centari-Pitch-Black-99A-(Quart).html

View attachment 216877

It’s called character!

Absolutely.I at least get to take for a spin around the block once

Been hotter'n Hades here lately.... heat indexes north of 100° 'bout every day. Braved the saunna... aka garage for a bit. Polished the swingarm spindle and greased. Down to my last tube of AeroShell 6. Guess I'll actually need to buy grease from now on.

Didn't get any pics, but the pivot plate holes are very close tolerance... for a BSA anyway.

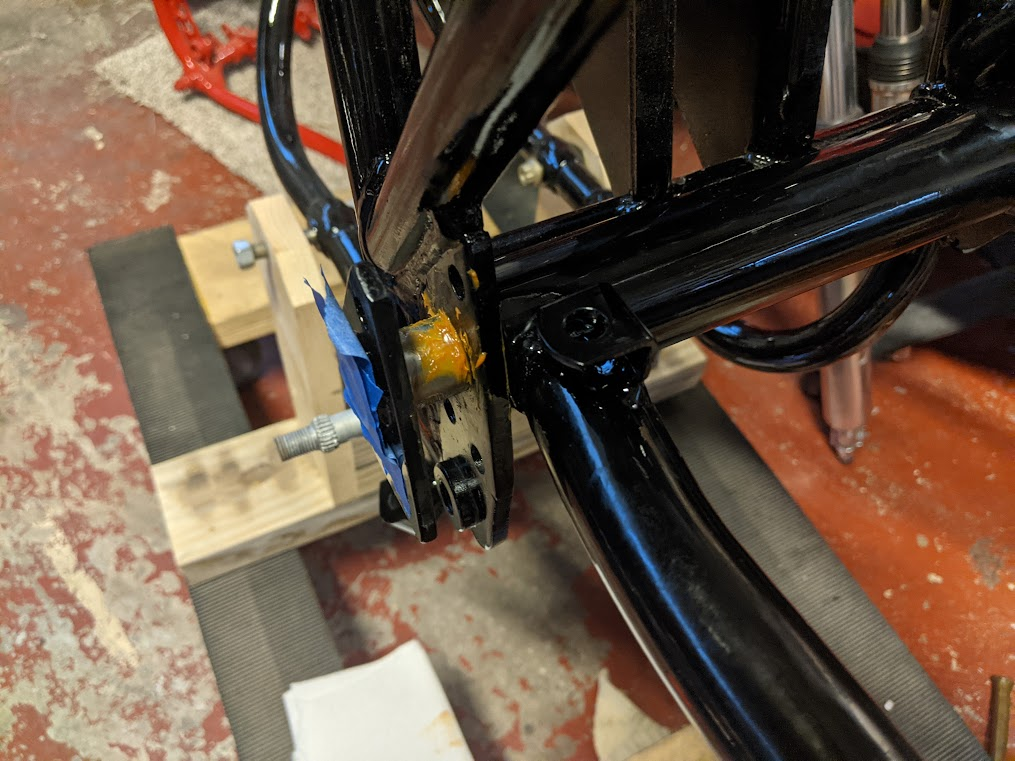

Cleaned the paint from the holes and still too tight. Had to polish the hole with some 320 paper, and then it still took good whacks with the deadblow to drive it in. Need to get off my ass and order some hardware from Feked UK.

Anyway, swingarm's in... close enough.

Just thought, this is actually the first assembly task. Better step my game up some.

"A journey of a thousand miles begins with a single step." Laozi.

Didn't get any pics, but the pivot plate holes are very close tolerance... for a BSA anyway.

Cleaned the paint from the holes and still too tight. Had to polish the hole with some 320 paper, and then it still took good whacks with the deadblow to drive it in. Need to get off my ass and order some hardware from Feked UK.

Anyway, swingarm's in... close enough.

Just thought, this is actually the first assembly task. Better step my game up some.

"A journey of a thousand miles begins with a single step." Laozi.

Been a day or two....

Time to get the rotation back in order.

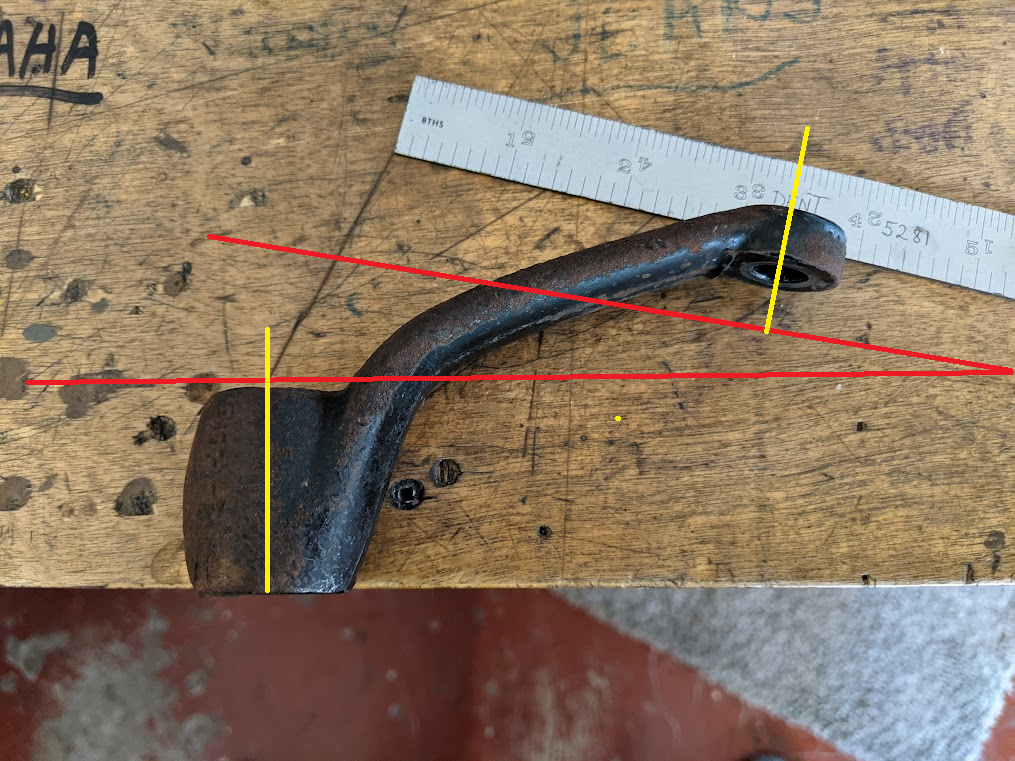

One of the footpeg mounts was bent. Can't say which 'cause I didn't label 'em when I pulled 'em off. It's bent in and up or down... most likely up from sliding. A two dimensional bend...

Used the vise and a long steel rod to take out the twist at the end.

... and the orange beast to flatten it out to the same shape as the other.

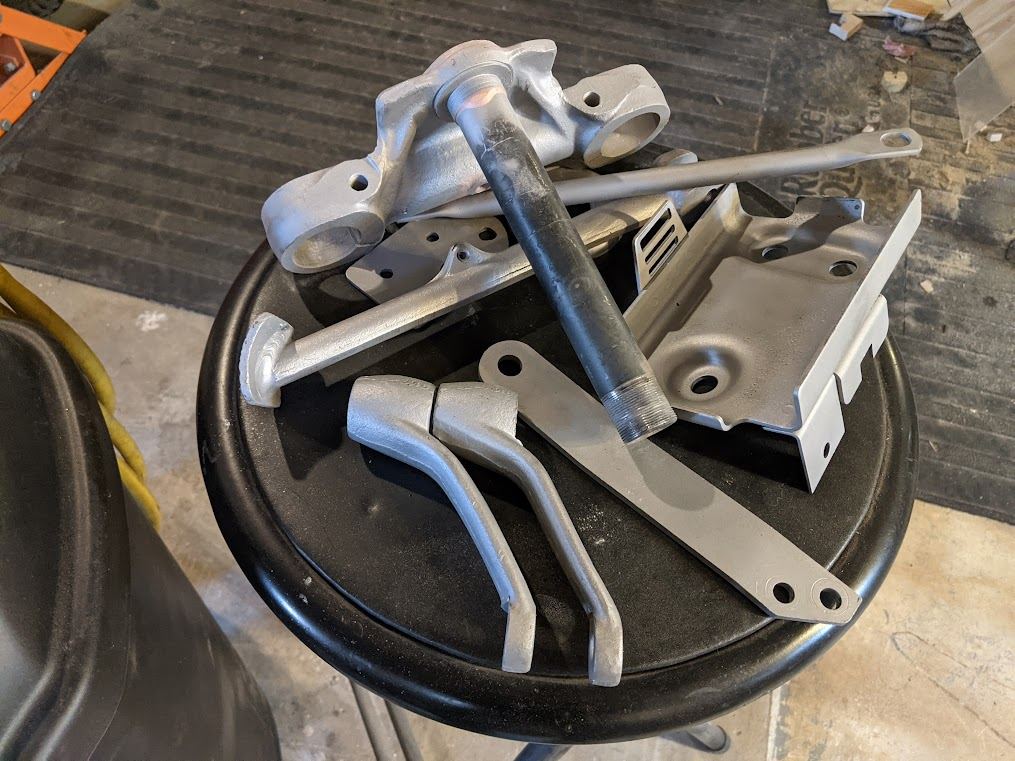

Cleanin' up the first batch of black bits for paint.

Time to get the rotation back in order.

One of the footpeg mounts was bent. Can't say which 'cause I didn't label 'em when I pulled 'em off. It's bent in and up or down... most likely up from sliding. A two dimensional bend...

Used the vise and a long steel rod to take out the twist at the end.

... and the orange beast to flatten it out to the same shape as the other.

Cleanin' up the first batch of black bits for paint.

Steady but methodical progress.

looking forward to the reveal.

looking forward to the reveal.

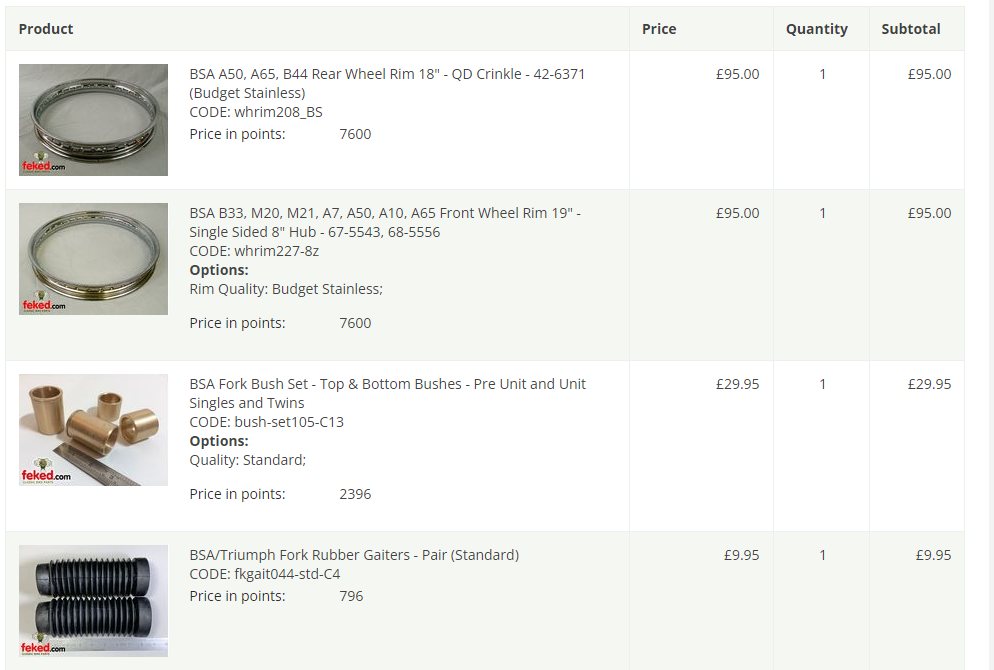

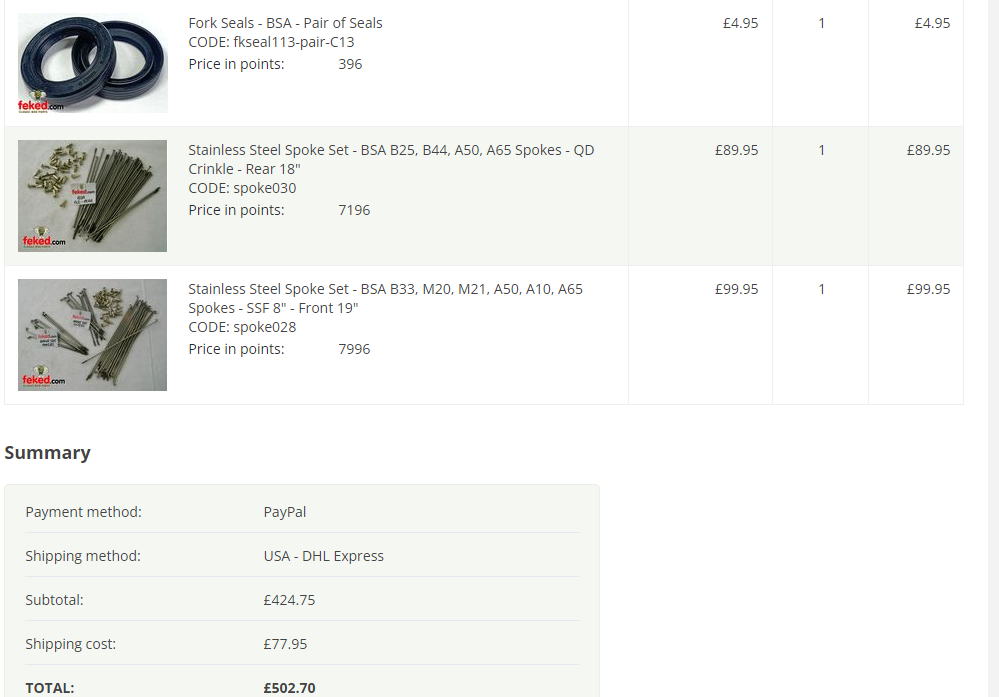

Shit jus' got serious....

I knew this day was coming... doesn't make it any easier to swallow though. Ouch!

Edit: As @Raymond subsequently points out, we're damn lucky there's folk like Feked out there to sell us the parts we need for 50+ yr old bikes.

For that, I'm grateful for the opportunity to spend my money there.

I knew this day was coming... doesn't make it any easier to swallow though. Ouch!

Edit: As @Raymond subsequently points out, we're damn lucky there's folk like Feked out there to sell us the parts we need for 50+ yr old bikes.

For that, I'm grateful for the opportunity to spend my money there.

Last edited: