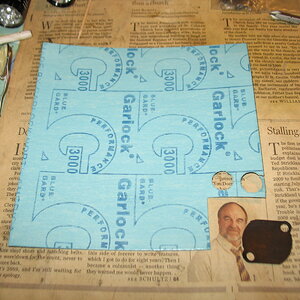

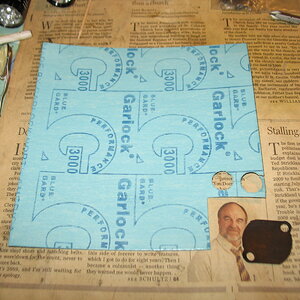

When I rebuilt the petcocks I used the Yamaha four-hole gaskets but thought the price for the rear gasket (under the plate) and the seal between petcock and tank were a bit steep for what they were and decided to try and make the gaskets myself and find an O-ring that would seal to the tank. I bought some Garlock 3000 sheet and some unreinforced Buna-N (same as most O-rings are made from) sheet from McMaster and used the back plate as a template to cut them out and a HF hole punch to punch the holes. I figured trying out one of each material would increase the chance of finding something that works and they weren’t expensive. I also made some sealing washers for one set of the petcock screws from the Garlock to see if the material would work there as well and the other I used copper crush washers.(also from McMaster) Here’s the part numbers for the sheet if anybody else wants to try this.

I thought it would be a good idea to bench test the petcocks before installing the gas tank on the bike (and hoping for the best) so I installed the petcocks and put about an inch of gas in the tank and let it sit with the petcocks off for about ten minutes. There were no leaks so I put them on reserve with a piece of clear tube to catch the gas and left them for three hours. There were still no drips or weeping so I turned them back to off, removed the tubing and will leave them overnight and see how they do.

So far, both materials are working as back gaskets and the Garlock and copper washers work as a sealing washer on the screws so we’ll see how they do long term. If they start to leak or the Garlock disintegrates, I will report back with the information.

As far as which one is better, the plain sheet is easier to cut but squeezes out easier so the screws can’t be tightened as much as with the Garlock but it’s harder to cut the Garlock cleanly so it’s kind of a tossup for me. I will probably stick with the plain rubber sheet as I like it better and it seems to work. Also the copper sealing washers, the used original sealing washers and the Garlock washers are all sealing as of now so it’s a use what you like/have situation there.

The O-ring I tried is also from McMaster (love that place) and is a 2mm x 35mm Buna-N. The groove was just a hair under 1.5 mm deep so with a 2mm diameter O-ring there is 0.5mm (0.020”) compression which is working so far.

I thought it would be a good idea to bench test the petcocks before installing the gas tank on the bike (and hoping for the best) so I installed the petcocks and put about an inch of gas in the tank and let it sit with the petcocks off for about ten minutes. There were no leaks so I put them on reserve with a piece of clear tube to catch the gas and left them for three hours. There were still no drips or weeping so I turned them back to off, removed the tubing and will leave them overnight and see how they do.

So far, both materials are working as back gaskets and the Garlock and copper washers work as a sealing washer on the screws so we’ll see how they do long term. If they start to leak or the Garlock disintegrates, I will report back with the information.

As far as which one is better, the plain sheet is easier to cut but squeezes out easier so the screws can’t be tightened as much as with the Garlock but it’s harder to cut the Garlock cleanly so it’s kind of a tossup for me. I will probably stick with the plain rubber sheet as I like it better and it seems to work. Also the copper sealing washers, the used original sealing washers and the Garlock washers are all sealing as of now so it’s a use what you like/have situation there.

The O-ring I tried is also from McMaster (love that place) and is a 2mm x 35mm Buna-N. The groove was just a hair under 1.5 mm deep so with a 2mm diameter O-ring there is 0.5mm (0.020”) compression which is working so far.

Last edited: