-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This is where the hairdryer comes in. I use it on stiff wiring and tubing. Makes things go limp.The master cylinder had leaked and the cylinder and the right hand controls were pretty crusty so I've been cleaning and rebuilding the switches.

This is what it looked like inside.

After much cleaning and lubing it's not going to win any beauty contests but it is functional and everything operates smoothly.

A quick scuff, prime and a couple coats of satin black and at least it's presentable.

I still need to fill in a couple of the recessed areas that used to have red paint and get some new stickers and it will be good to go.

The original loom was super stiff and brittle and no way was it possible to reinsert it into the handlebars so I got some heat shrink tubing from McMaster and put that over the wires, it will be a while before I'm ready to reinstall the switches but hoping it won't be too bad getting the wires back in the bars.

The left hand switches were in pretty good shape so they only needed a clean, lube and shrink tube and they now operate smoothly and are ready to reinstall as well.

Yes, I'm on my second one, lol. I won one as a door prize at a rally many years ago and thought what the heck am I going to do with this thing. Well, turns out I used the heck out of it for minor heating of things like fuel lines and wiring. I eventually wore the thing out and actually had to buy one, lol.

I also have a dedicated hair dryer just for my projects. It "died" a couple of years ago and was replaced. Before throwing it out I thought "what the heck, maybe I can fix it". Turns out one of the solder joints failed and just needed re-soldered.

I'm hoping with the new, more flexible sleeving on the wires and a string to pull it through while pushing it at the other end I will be OK but I'll remember the heating trick. Thankfully the wires are still flexible but the old sleeve was so brittle you could squeeze it hard between finger and thumb and it would crack into little pieces and it cracked in multiple places when removing from the handlebars.

5twins I like your license plate reinforcement, very pro.

I'm hoping with the new, more flexible sleeving on the wires and a string to pull it through while pushing it at the other end I will be OK but I'll remember the heating trick. Thankfully the wires are still flexible but the old sleeve was so brittle you could squeeze it hard between finger and thumb and it would crack into little pieces and it cracked in multiple places when removing from the handlebars.

5twins I like your license plate reinforcement, very pro.

Great Reading, Mike G! Curious about the clutch lever bolt - it was worn the same way on my TX650A. Those carbs are clean inside. Amazing

Thanks TX650A, they cleaned up WAAAY better than I thought they would.

This weekend I decided to tackle taking the front end apart and inspecting and disassembling the forks.

I read MaxPete's excellent writeup on rebuilding the early forks and figured I probably had something laying around I could make a tool to hold the damper rods. As I was going through my scrap bin I decided I might as well try removing the damper rod bolt without the tool and miracle of miracles, a sharp rap on the hex wrench with my hand and both damper rod bolts came right out! Surprise surprise...sometime you get lucky. I may still need a tool to tighten the bolts for assembly but it will be a lot easier to make it and check the fit with the damper rods in my hand. The fork seals were leaking and there is some rust below the triple trees which may be in the seal travel area. Once I got the springs out and the dust boots off it was easy to see that the rust is not a problem and the rust above the seal area cleaned up well with 800 grit sand paper.

The damper rods were a little different than MaxPete’s so I thought those with the TX-A model might like to see what the parts look like. I have a set of 75 forks and that damper looks slightly different so apparently Yamaha was playing around with dampers during this period. The larger diameter parts to the left are actually held inside the fork tube with a snap ring. At least I think they all do, when I pulled the damper rods out I took the whole thing out the bottom of the tube so not 100% sure they all came out of the tube. I will know for sure when I put the forks back together but since they are all the same diameter it makes sense they all go back in the tube.

This weekend I decided to tackle taking the front end apart and inspecting and disassembling the forks.

I read MaxPete's excellent writeup on rebuilding the early forks and figured I probably had something laying around I could make a tool to hold the damper rods. As I was going through my scrap bin I decided I might as well try removing the damper rod bolt without the tool and miracle of miracles, a sharp rap on the hex wrench with my hand and both damper rod bolts came right out! Surprise surprise...sometime you get lucky. I may still need a tool to tighten the bolts for assembly but it will be a lot easier to make it and check the fit with the damper rods in my hand. The fork seals were leaking and there is some rust below the triple trees which may be in the seal travel area. Once I got the springs out and the dust boots off it was easy to see that the rust is not a problem and the rust above the seal area cleaned up well with 800 grit sand paper.

The damper rods were a little different than MaxPete’s so I thought those with the TX-A model might like to see what the parts look like. I have a set of 75 forks and that damper looks slightly different so apparently Yamaha was playing around with dampers during this period. The larger diameter parts to the left are actually held inside the fork tube with a snap ring. At least I think they all do, when I pulled the damper rods out I took the whole thing out the bottom of the tube so not 100% sure they all came out of the tube. I will know for sure when I put the forks back together but since they are all the same diameter it makes sense they all go back in the tube.

Today I decided I wanted to see a little bling so I polished up the fender and stays with some chrome polish and #0000 steel wool.

Before...

After...

I was pleased with the way they came out. From ten feet you can’t see the rust pimples, at least I can’t.

That was pretty motivating so I decided to clean up the handlebars, headlight ring and mirrors.

Just so you don’t imagine they are nicer than they are here is a closeup of one of the mirrors and you can clearly see the rust pits.

I like the tuning fork on the opposite mirror.

Again, from ten feet they will look OK, so for a small investment in elbow grease they look reasonably presentable and they are (or at least I think they are) original and I like the idea that they are still doing the job after almost 50 years.

Before...

After...

I was pleased with the way they came out. From ten feet you can’t see the rust pimples, at least I can’t.

That was pretty motivating so I decided to clean up the handlebars, headlight ring and mirrors.

Just so you don’t imagine they are nicer than they are here is a closeup of one of the mirrors and you can clearly see the rust pits.

I like the tuning fork on the opposite mirror.

Again, from ten feet they will look OK, so for a small investment in elbow grease they look reasonably presentable and they are (or at least I think they are) original and I like the idea that they are still doing the job after almost 50 years.

Today I decided I wanted to see a little bling so I polished up the fender and stays with some chrome polish and #0000 steel wool.

Before...

After...

I was pleased with the way they came out. From ten feet you can’t see the rust pimples, at least I can’t.

That was pretty motivating so I decided to clean up the handlebars, headlight ring and mirrors.

Just so you don’t imagine they are nicer than they are here is a closeup of one of the mirrors and you can clearly see the rust pits.

I like the tuning fork on the opposite mirror.

Again, from ten feet they will look OK, so for a small investment in elbow grease they look reasonably presentable and they are (or at least I think they are) original and I like the idea that they are still doing the job after almost 50 years.

Nice save on the chrome! It’s amazing how well chrome responds to a good cleaning. Your fork damping internal parts look the same as my XS2. Nice work!

Ahh, makes sense and explains why one is rusty and the other very nice (for the age). Thanks for the info 5twins.

I'm going to check the cam chain adjustment and valve clearance next. IIRC many set their valves to .006" Exh. and .004" Int. which sounds like good/typical numbers to me. That's what I did on the SG, it makes the valves a little "tappy", particularly when cold but I've always heard "a tappy valve is a happy valve".

I'm going to check the cam chain adjustment and valve clearance next. IIRC many set their valves to .006" Exh. and .004" Int. which sounds like good/typical numbers to me. That's what I did on the SG, it makes the valves a little "tappy", particularly when cold but I've always heard "a tappy valve is a happy valve".

All the valves were about .001" over the .004/.006" clearance, adjusting the XS valves is almost as easy as a BMW airhead, almost.

The plunger in the cam chain adjuster was down inside about 3/16-1/4"!! I would think that would make the chain awfully loose and probably rattly. Maybe that's why there were some shiny flakes in the oil screens The plunger is now close to flush and moves in and out a bit when turning over, glad I checked it.

The plunger is now close to flush and moves in and out a bit when turning over, glad I checked it.

Check those off the list...

The plunger in the cam chain adjuster was down inside about 3/16-1/4"!! I would think that would make the chain awfully loose and probably rattly. Maybe that's why there were some shiny flakes in the oil screens

The plunger is now close to flush and moves in and out a bit when turning over, glad I checked it.

The plunger is now close to flush and moves in and out a bit when turning over, glad I checked it.Check those off the list...

I will have to try that. For now I think I will leave it a little big just because the bike has sat so long there could be rust/crud/who knows what on the seats/valves and if they close up after running they will still be good. After I run it 100 miles or so I will check them again and then try the .003".

Kind of funny the way Yamaha played around with valve clearance even though the engines are all but identical. It would be nice to hear the head engineers explanation of what they were trying to achieve and what the result was for each change.

Kind of funny the way Yamaha played around with valve clearance even though the engines are all but identical. It would be nice to hear the head engineers explanation of what they were trying to achieve and what the result was for each change.

If you do a forum search on "valve lash", you'll get almost 500 hits.

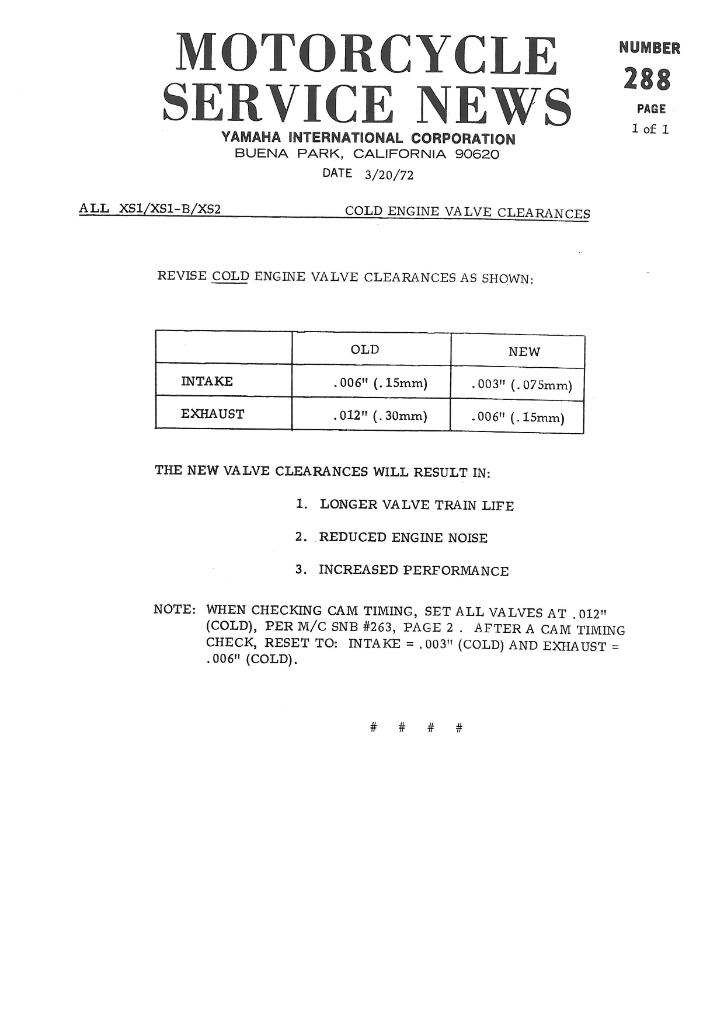

Original XS1/XS1B/XS2 callouts were for 0.006" and 0.012".

Then came the service bulletin.

I've played with settings in between those specs, ran 0.005" / 0.010" for a long time. Seemed to have a little more *grunt* at low revs with the looser settings. Have long suspected that the revised callout came from marketing, not engineering...

Original XS1/XS1B/XS2 callouts were for 0.006" and 0.012".

Then came the service bulletin.

I've played with settings in between those specs, ran 0.005" / 0.010" for a long time. Seemed to have a little more *grunt* at low revs with the looser settings. Have long suspected that the revised callout came from marketing, not engineering...

I did a little work on the gauges last night. I wanted to clean the contacts in the ignition switch like I did on the SG (which badly needed it) and clean up the chrome housings. There wasn't nearly as much "stuff" in the ignition switch of the TX so cleaning it was a snap. I don't have any after picture (not that different anyway) but here's what it looked like inside.

The chrome polished up decent but has more pits than the fender did but from 10 feet (my unofficial yardstick) it looks OK-ish.

I cleaned all the spiderwebs from inside the instrument housing, installed the ignition switch, buttoned everything up and they look reasonably good.

Even the foam dampers under the gauges were still soft and flexible. They must have shrunk some as the gauges are not quite as snug in the housing as I would like so I may put something (plastic ring of some sort maybe?) in there to tighten them up a bit.

I installed the speedo cable into each of the gauges and spun it with a drill. The tach worked but the speedo didn't, maybe the needle will break loose with a little of that famous XS (TX) vibration otherwise I may have to open them up, which I would rather not do...

The chrome polished up decent but has more pits than the fender did but from 10 feet (my unofficial yardstick) it looks OK-ish.

I cleaned all the spiderwebs from inside the instrument housing, installed the ignition switch, buttoned everything up and they look reasonably good.

Even the foam dampers under the gauges were still soft and flexible. They must have shrunk some as the gauges are not quite as snug in the housing as I would like so I may put something (plastic ring of some sort maybe?) in there to tighten them up a bit.

I installed the speedo cable into each of the gauges and spun it with a drill. The tach worked but the speedo didn't, maybe the needle will break loose with a little of that famous XS (TX) vibration otherwise I may have to open them up, which I would rather not do...

AndersJ

XS650 Addict

A note on the tire discussion. My 74' tx650 with an indicated 3000 on the odometer (in a similar cosmetic shape as yours) has the same front and rear tire as well.

Betcha can't guess what I was doing today...

I don't have the patience to do a mirror polish, my hat's off to those that do cuz it sure is pretty.

On the SG I dry sanded before polishing with Tripoli on the bench grinder followed with a quick hand polish with Never-Dull. This time I did the same with the exception of trying wet sanding in a tub of soapy water as some have recommended. It was a bit easier but still a lot of work. Tomorrow I will start the right side cover. I think the left cover is the hardest because of the shape and it was in the worst shape of all the aluminum on the bike.(Right side is not far behind though.) That's why I did it first, to get it out of the way.

I don't have the patience to do a mirror polish, my hat's off to those that do cuz it sure is pretty.

On the SG I dry sanded before polishing with Tripoli on the bench grinder followed with a quick hand polish with Never-Dull. This time I did the same with the exception of trying wet sanding in a tub of soapy water as some have recommended. It was a bit easier but still a lot of work. Tomorrow I will start the right side cover. I think the left cover is the hardest because of the shape and it was in the worst shape of all the aluminum on the bike.(Right side is not far behind though.) That's why I did it first, to get it out of the way.

And todays progress...

Next, the fork lowers.

Next, the fork lowers.

Looking very nice , you’re making good progress!

Thanks mailman, I appreciate it! I'm glad to get those two out of the way.