I had some more "tweaking" to do yesterday after getting the wheels back in. When I tried to spin the rear wheel, it had a pretty good drag it on coming from the brake. I had sanded the drum half-heartedly to get the worst of the rust off but apparently there was enough left to cause some drag so I sanded it completely clean. I put the wheel back in but there was still more drag than I liked so I spun the wheel a bunch to make rub marks and the leading and trailing edges of the shoes needed a little sanding to allow the wheel to spin freely.

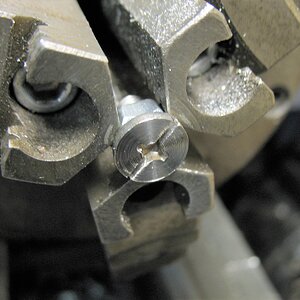

While spinning the front wheel, I heard tick, tick tick... as the lower inside edge of the caliper hit the back side of the disk buttons. I never really looked at them as they were smaller than the front side of the buttons, but they were also taller. I put some machinists blue on the buttons and spun the wheel a bunch to mark-up the buttons and the caliper.

I little work with a file and now there is about 0.060" between the caliper and the disk buttons.

The chamfer at the bottom of the caliper wasn't required for clearance, it was just easier to file the whole surface to remove the sharp corner next to the bore and it reduced the weight by at least 1/2 a gram which should increase cornering speed and flick-ability in quick left-right transitions...

Hopefully this helps anyone thinking of putting an FZR, or similar modern disk on a bike with the twin piston caliper.

While spinning the front wheel, I heard tick, tick tick... as the lower inside edge of the caliper hit the back side of the disk buttons. I never really looked at them as they were smaller than the front side of the buttons, but they were also taller. I put some machinists blue on the buttons and spun the wheel a bunch to mark-up the buttons and the caliper.

I little work with a file and now there is about 0.060" between the caliper and the disk buttons.

The chamfer at the bottom of the caliper wasn't required for clearance, it was just easier to file the whole surface to remove the sharp corner next to the bore and it reduced the weight by at least 1/2 a gram which should increase cornering speed and flick-ability in quick left-right transitions...

Hopefully this helps anyone thinking of putting an FZR, or similar modern disk on a bike with the twin piston caliper.

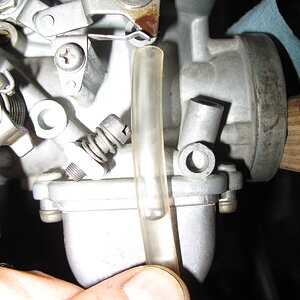

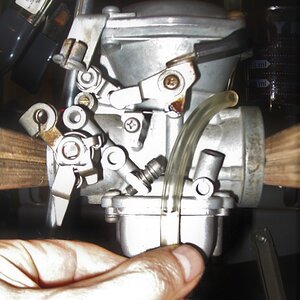

PS, I’m sure you already know this, but I’ll say it just in case. The choke has to be in the on position to test your slide. Here is a link to my choke issue,

PS, I’m sure you already know this, but I’ll say it just in case. The choke has to be in the on position to test your slide. Here is a link to my choke issue,