-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alternative slipping starter gear spring fix.

- Thread starter toglhot

- Start date

stinky78

XS650 Addict

Aussie ingenuity!

Some day when I get up some ambition I'll have to give this one a try on the 1982!

Excellent suggestion toglhot. When my current fix fails, I'll try yours.

Cheers mate

Cheers mate

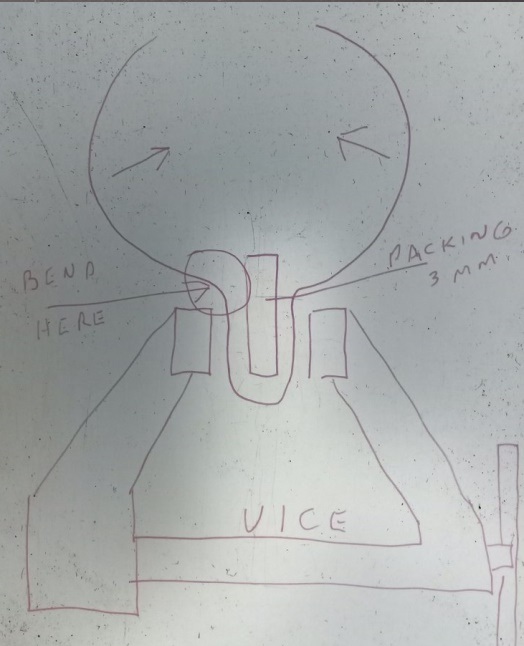

Good idea I still have another spring and the old gearHere's a tip on fixing a slipping starter gear spring. There are plenty of articles written on fixing the problem, but they all revolve around putting the tight U bend in the vice and closing it up. Not a very good method to my way of thing for a couple of reasons: By bending the U shape to such an acute angle the spring steel is weakened, and secondly, it may not bend in the large curves that grip the gear enough to provide enough tension to stop the gear rotating. Luckily, I had a spare, used spring, which I used to effect the fix as per the plethora of articles on the web. Then I installed the spring on the gear, connected a weight scale to the spring and pulled, the spring rotated around the gear with nothing like the pressure needed to grip the gear and stop it from rotating. So, that stuffed the spring which left either buying new spring, which also includes a new gear, or coming up with a better mouse trap..

So, armed with that failure and thinking cap on, I nutted out a better mouse trap: I placed the U bend in the vice as before, except this time I placed a piece of 3mm thick steel in the U bend and tightened the vice, thus stopping the U bend from being bent. I then grabbed each end of the two large half circle bits and bent them inward. I then carried out the same test to see if the spring would rotate on the gear with the factory stated pressure applied, Not a hope in hell, the spring held firmly until well after the stated pressure was applied. When the motor was finally assembled and started, the spring did the job, despite the motor being started many, many times.

If you're into fabricating steel as much as I am, you could easily anneal a piece of spring steel of the right diameter, perhaps larger if it will fit, bend to the shape required and then re harden the spring.

The picture shows what I mean, a bit rough, but you'll get the idea when matched with the narrative.

Bending the spring at the point shown does not weaken the metal as much as at the U bend because the bend is not so acute, very slight in fact. But best of all, if needed, you can do this mod several times on the same spring if required.

I'm going to give that a go just out of curiosity

Thanks !

Do you suppose if I have that tail end of that clip bent in past the 3mm now that this fix should still workI inverted the colors. I think it's easier to see this way .....

I can't see why not

I don't see why not. 3mm is about 1/8" so I figured I'd just cut a small strip of 1/8" thick steel to force into the little loop, maybe one of the legs off some small angle iron. The leg off some angle iron would have the added benefit of having it's outer edge rounded over. That should fit nicely into the loop bend.

I have that spare old wore out gear and a clipI don't see why not. 3mm is about 1/8" so I figured I'd just cut a small strip of 1/8" thick steel to force into the little loop, maybe one of the legs off some small angle iron. The leg off some angle iron would have the added benefit of having it's outer edge rounded over. That should fit nicely into the loop bend.

I'm going to give it a try

Do you have a fishing scale to test it? If so, give us a before and after pull reading. Toglhot said this made his much better but didn't give an actual pounds of pull figure. I think the factory spec is around 5 pounds, and we shoot for 6 to 8.

I'm going to have to use the old a pint is a pound method with an old plastic milk container

I know 1 gal of water weighs approx. 8 lbs so that should be good enough for a start

I know 1 gal of water weighs approx. 8 lbs so that should be good enough for a start

glennpm

Another Old Biker Nut!

I just did this with a replacement spring from Yamaha with a new gear, hairpin spring and light wire coil spring.

As is the hairpin slipped. After the fix I was getting 8 to 9+ on my fish scale.

Just a comment on "fracturing" it is local yielding and not fracturing of the spring steel. Enough cycles though, over bending or a small nick at the bend could cause a yield fracture failure.

Thanks for sharing this method, it works great!

As is the hairpin slipped. After the fix I was getting 8 to 9+ on my fish scale.

Just a comment on "fracturing" it is local yielding and not fracturing of the spring steel. Enough cycles though, over bending or a small nick at the bend could cause a yield fracture failure.

Thanks for sharing this method, it works great!

Low carbon steel: .25 percent, low strength, high ductility. Used for general fabrication as it’s easy to work with bend, etc. Used for car and bike parts such as frames, tanks, sweatpants, mudguards, nails, sheet steel, etc.

Medium carbon steel: .25 - 6 percent carbon. Heating and quenching give it a martensitic structure, ie, the cooling rate is fast enough to prevent carbon atoms from diffusing. MC steels have higher strength but less ductility. Used for crankshafts, gears, Machinery parts, axles, hammers, etc.

High carbon steel: .6 - 1.25 percent. Highest hardness and toughness but lowest ductility. Used for cutting tools, springs, musical instrument strings, etc.

The higher the carbon content the more brittle the steel becomes when heat treated. Indeed, if quenched quick enough, as in ordinary water, the steel will become very brittle, and may crack and fracture during the process. If quenched a little slower in say salt water, oil or blood the less likely it is to fracture but it will still remain brittle. That brittleness can be lessened by tempering. The tempering process is dependent on what the steel is to be used for: Cutting tools, springs, knives, machine parts, etc.

Fracture definition: Cracking or breaking of a hard object.

Bend hardened high carbon steel, as in spring steel and you risk cracking or breaking the structure, ie, it may ‘fracture’! Of course, not all springs are created equal, the hardness of the steel used in the spring governs the ‘fracturing’ or breakability.

One way to test a spring’s hardness or breakability, is to bend it and see if it breaks or ‘fractures’. The more acute the bend the more likely it is to ‘fracture’, or break. Whereas a slight bend around a larger radius is more in keeping with the springs intentional design purpose. But not ideal when dealing with hardened steel parts inside an internal combustion engine.

Pedantic definition: excessively concerned with minor details or rules;

That is according to the dictionary, for me it just means ‘silly’!

Silly definition: having or showing a lack of common sense or judgement; absurd and foolish.

Now I’m sure the pedant can find more to lend his lack of common sense to in the above, but that would just be really ‘silly’!

Medium carbon steel: .25 - 6 percent carbon. Heating and quenching give it a martensitic structure, ie, the cooling rate is fast enough to prevent carbon atoms from diffusing. MC steels have higher strength but less ductility. Used for crankshafts, gears, Machinery parts, axles, hammers, etc.

High carbon steel: .6 - 1.25 percent. Highest hardness and toughness but lowest ductility. Used for cutting tools, springs, musical instrument strings, etc.

The higher the carbon content the more brittle the steel becomes when heat treated. Indeed, if quenched quick enough, as in ordinary water, the steel will become very brittle, and may crack and fracture during the process. If quenched a little slower in say salt water, oil or blood the less likely it is to fracture but it will still remain brittle. That brittleness can be lessened by tempering. The tempering process is dependent on what the steel is to be used for: Cutting tools, springs, knives, machine parts, etc.

Fracture definition: Cracking or breaking of a hard object.

Bend hardened high carbon steel, as in spring steel and you risk cracking or breaking the structure, ie, it may ‘fracture’! Of course, not all springs are created equal, the hardness of the steel used in the spring governs the ‘fracturing’ or breakability.

One way to test a spring’s hardness or breakability, is to bend it and see if it breaks or ‘fractures’. The more acute the bend the more likely it is to ‘fracture’, or break. Whereas a slight bend around a larger radius is more in keeping with the springs intentional design purpose. But not ideal when dealing with hardened steel parts inside an internal combustion engine.

Pedantic definition: excessively concerned with minor details or rules;

That is according to the dictionary, for me it just means ‘silly’!

Silly definition: having or showing a lack of common sense or judgement; absurd and foolish.

Now I’m sure the pedant can find more to lend his lack of common sense to in the above, but that would just be really ‘silly’!

Similar threads

- Replies

- 26

- Views

- 769