GoldenEye

XS650 Member

Morning all!

I’ve been using the advice on this forum for the past 3 years while putting back together/building my ’73 that I bought in pieces, but I’m stuck now (have been for ~2 weeks) so I’m hoping someone has a word of advice and the patience to read this novel I seem to have written.

Bike:

’73 frame

’72 motor

’74-‘75 BS38 Carbs (4N8 needle, unlinked, choke on left side only) with floats set at 24mm and mix screws at ¾ turn, bench synced with sighting to a light and then thin strip of paper.

K&N pods with cut down stock headers that reach the foot pegs and have homebrewed baffles

New:

All gaskets and O-rings

Cam chain

Valve stem seals (valves were lapped before reassembly)

Wiring (strung it myself)

PMA conversion with Banshee rotor

JBM Industries carb mounts and diaphragms

Updates:

Pamco ignition, mechanical advance

Dual output coil from Mikes (17-6903 High Output)

Upped pilot jets from 45 to 47.5 (1 size and genuine jets from local dealer)

Upped mains from 127.5 to 132.5 (2 sizes and genuine jets from local dealer)

Engine specs:

Compression is 170/165 on the right/left respectively

Capacitors charge at 14.4 volts when the bike is running

Fuel is 93 octane running through an inline filter off a newer and freshly coated alien tank

Where I am stuck:

Rebuilt the engine, got it back in the frame, set cam chain tension to flush, buttoned up with valve lash set to .006 intake and .012 exhaust, set Pamco to center of adjustment area, then fired it up and put a timing light on it. It ran long enough to time it (had to move almost all the way advanced, CW) but it didn’t WANT to run. I pulled the carbs, cleaned them from top to bottom (except the throttle shaft which I am doing when I get a chance in the next few days to get some JIS screwdrivers for the plate screws) using the almighty carb guide (HUGE thanks to all who contributed) and put it back together and still no dice. It sounds okay for maybe 10-15 seconds and then does what I can only describe as “woofing” through the carbs with a nice cloud of fuel vapor coming out of the throat before it dies. It also coats the carb throat in what looks to me like a mix of carbon and fuel since I can wipe it out with a shop towel and the residue is dark and smells like gas.

Now, I took quite a bit of time to read through the forum and try to make sure my cam is positioned correctly in relation to my crank and I have found the following.

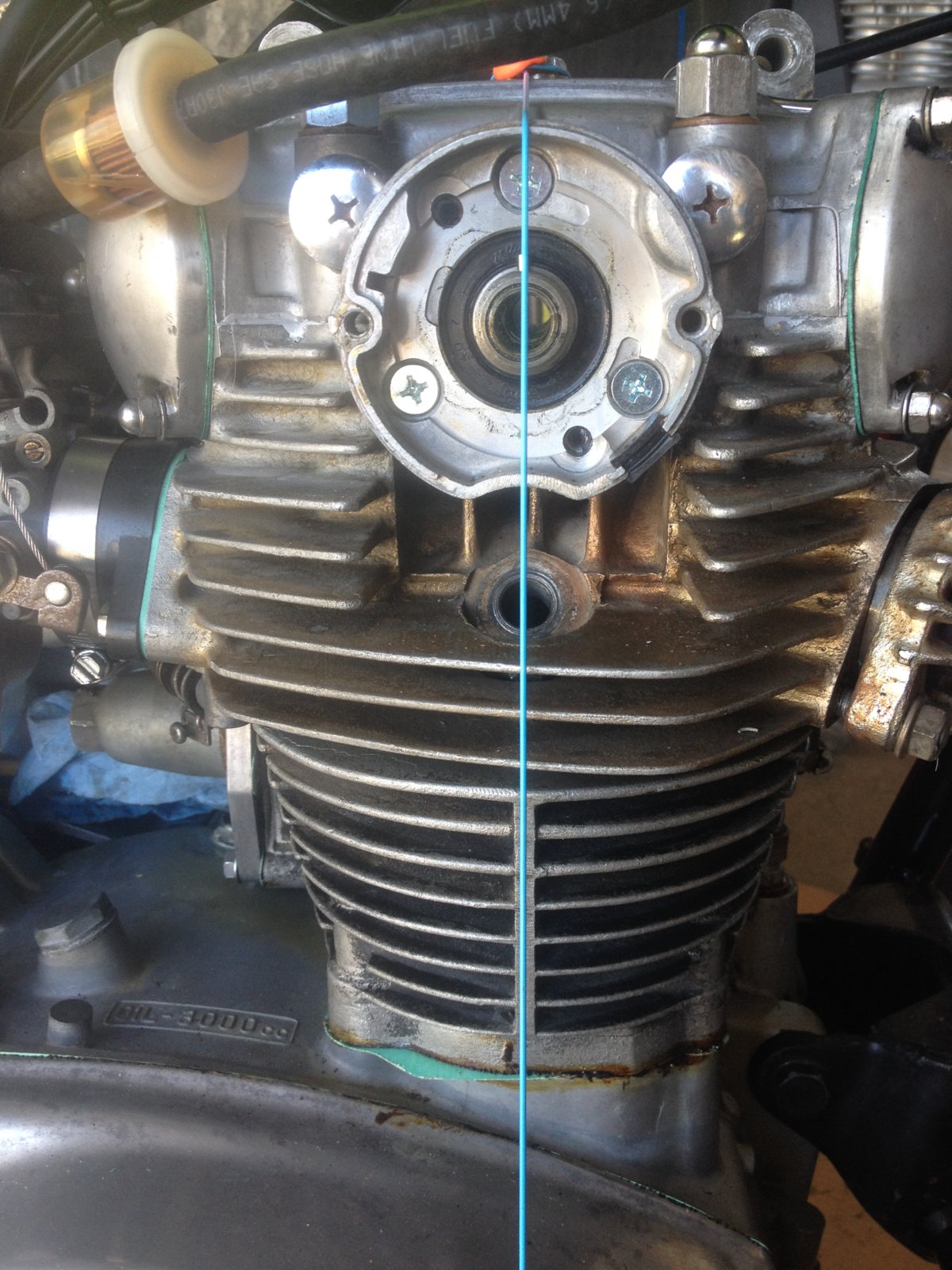

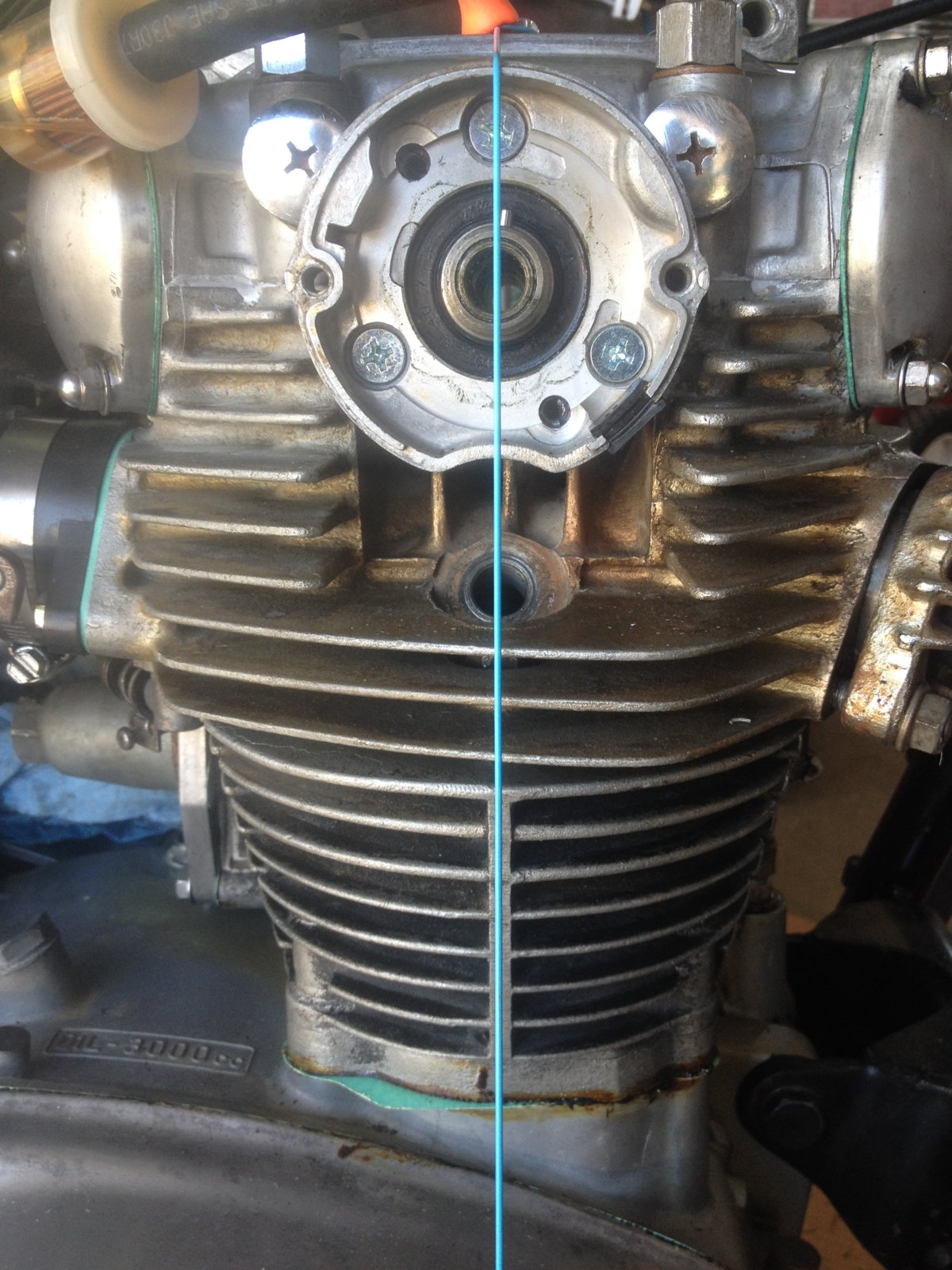

Started by finding TDC with my homemade piston stop, “precisely” super glued a printed degree wheel to my rotor which you will see in a hot minute, and determined that my handiwork had fetched me a TDC at about 1° on the degree wheel (can’t adjust, super glue…) at which time I also took a picture of the cam pin position on the ATU side of the bike.

From here you can see it is NOT at 12 O’clock, marked out with my nifty earplug string and some duct tape setup, so I proceeded to move the crank in 5° increments (2.5° at the cam) to see where it became vertical.

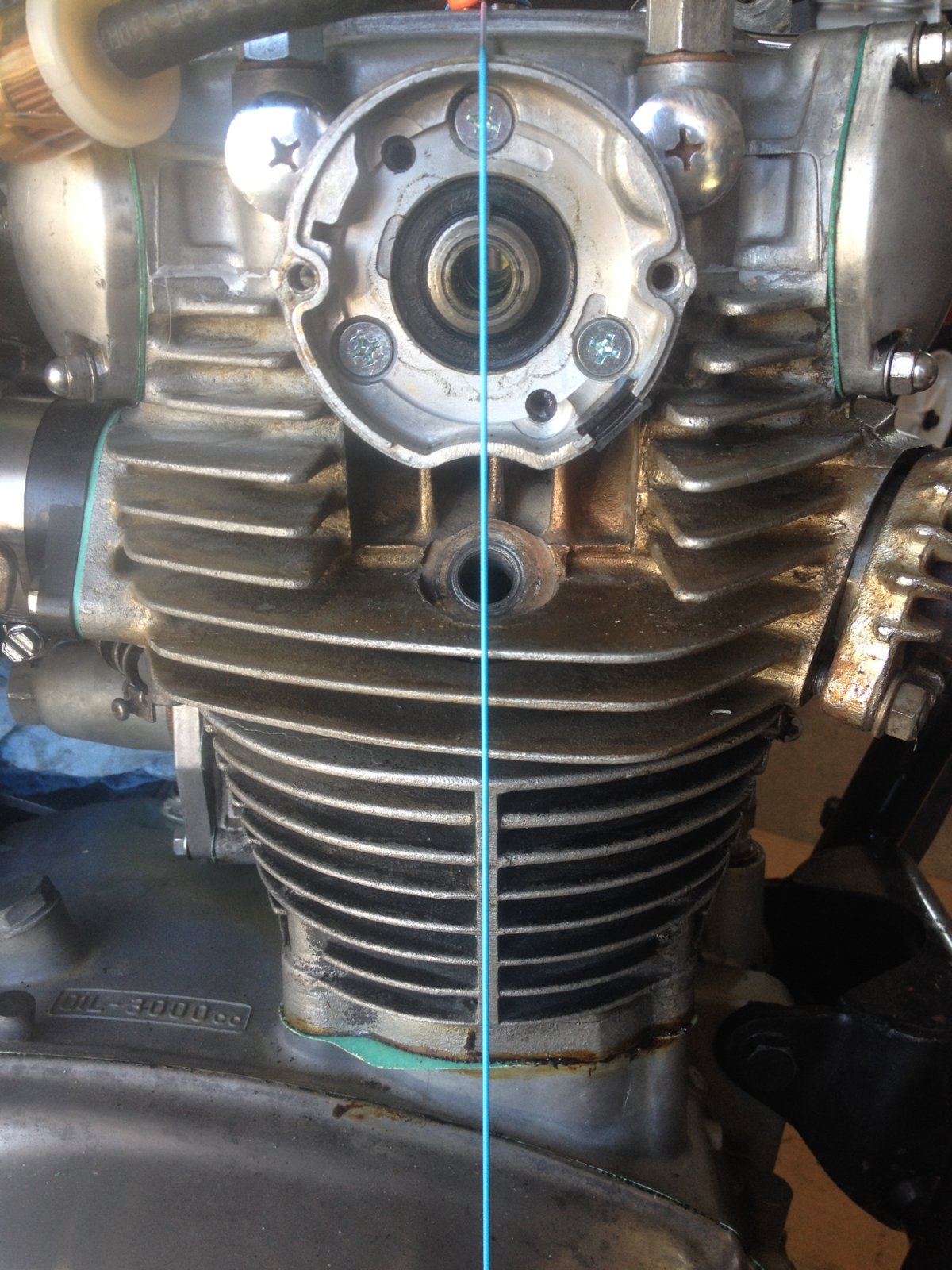

So here is the picture at 5° ATDC

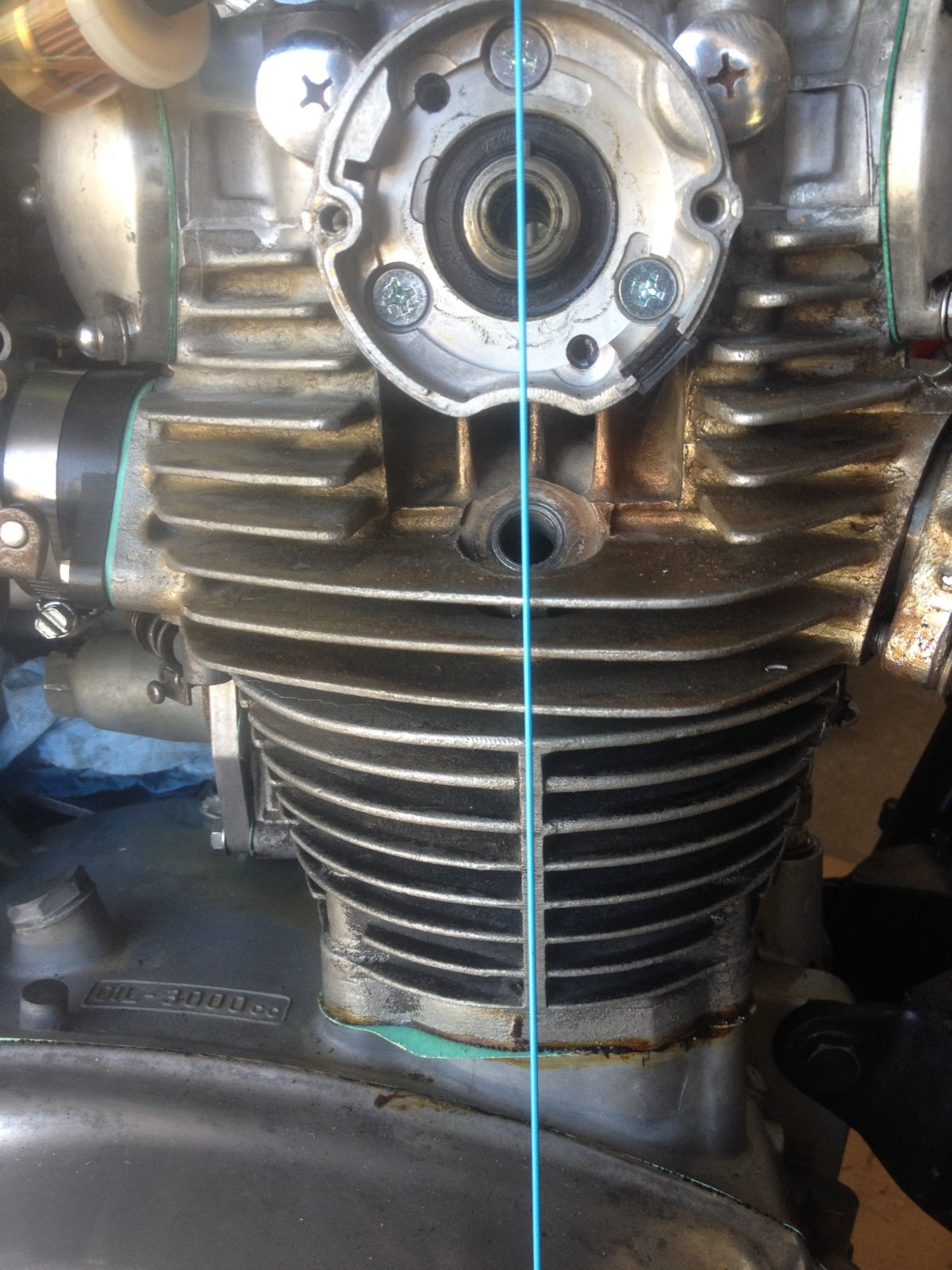

10° ATDC

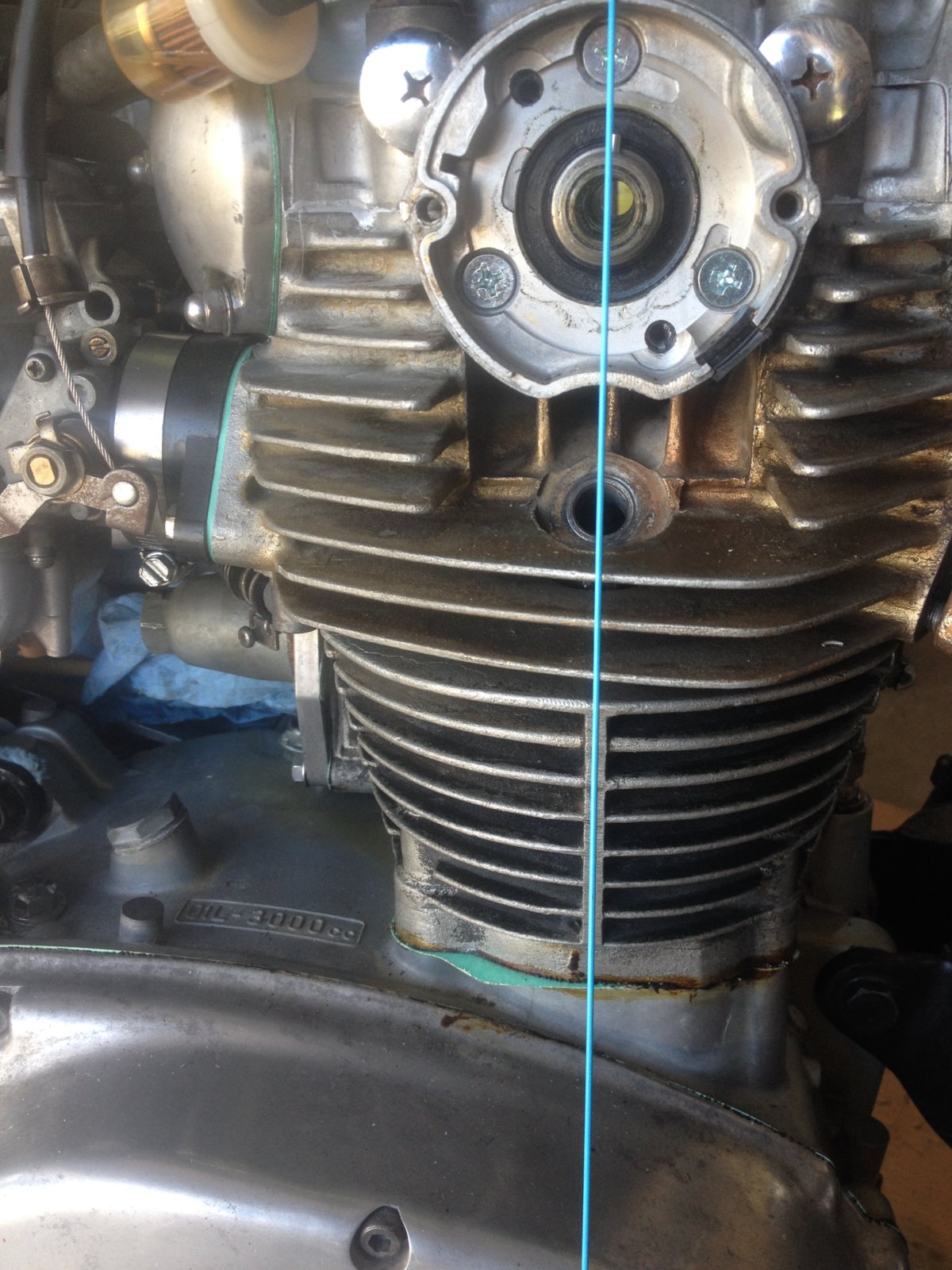

15° ATDC

And finally 20° ATDC which is where, if I understand correctly, one tooth forward would be if I moved the cam

To me, the 5° ATDC seemed like the closest to vertical I could get but being that that is ~2.5 degrees at the cam I would think this would be okay right?

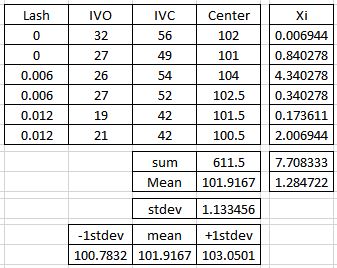

But after seeing this, and reading some more, I went out and bought a dial indicator and decided I was going to find out once and for all if that cam was in the right position. With the new tool, a harbor freight special, I took measurements and this is what I got for the intake lobe center.

While they aren’t perfect, 5/6 come out within a standard deviation and the only one that does not is the 104 measurement. The spec for the 256 cam intake as far as I can tell is 100°, so I am about 2° retarded at the crank or 1° at the cam right? This seems to tell me that I am in the right tooth position on the cam, but the only explanation I can convince myself of is that the “woofing” of the fuel vapor through the carb throat is from being a tooth off and having my intakes open/close late which keeps the valve open during compression.

Has anyone seen this before or have any thoughts on the matter? I am about at my wits end with this bike, but I love it too much to give up and buy anything else so I’m hoping someone/anyone was willing to read through all of that and hopefully tell me what I am missing?

Big thanks in advance,

GoldenEye

I’ve been using the advice on this forum for the past 3 years while putting back together/building my ’73 that I bought in pieces, but I’m stuck now (have been for ~2 weeks) so I’m hoping someone has a word of advice and the patience to read this novel I seem to have written.

Bike:

’73 frame

’72 motor

’74-‘75 BS38 Carbs (4N8 needle, unlinked, choke on left side only) with floats set at 24mm and mix screws at ¾ turn, bench synced with sighting to a light and then thin strip of paper.

K&N pods with cut down stock headers that reach the foot pegs and have homebrewed baffles

New:

All gaskets and O-rings

Cam chain

Valve stem seals (valves were lapped before reassembly)

Wiring (strung it myself)

PMA conversion with Banshee rotor

JBM Industries carb mounts and diaphragms

Updates:

Pamco ignition, mechanical advance

Dual output coil from Mikes (17-6903 High Output)

Upped pilot jets from 45 to 47.5 (1 size and genuine jets from local dealer)

Upped mains from 127.5 to 132.5 (2 sizes and genuine jets from local dealer)

Engine specs:

Compression is 170/165 on the right/left respectively

Capacitors charge at 14.4 volts when the bike is running

Fuel is 93 octane running through an inline filter off a newer and freshly coated alien tank

Where I am stuck:

Rebuilt the engine, got it back in the frame, set cam chain tension to flush, buttoned up with valve lash set to .006 intake and .012 exhaust, set Pamco to center of adjustment area, then fired it up and put a timing light on it. It ran long enough to time it (had to move almost all the way advanced, CW) but it didn’t WANT to run. I pulled the carbs, cleaned them from top to bottom (except the throttle shaft which I am doing when I get a chance in the next few days to get some JIS screwdrivers for the plate screws) using the almighty carb guide (HUGE thanks to all who contributed) and put it back together and still no dice. It sounds okay for maybe 10-15 seconds and then does what I can only describe as “woofing” through the carbs with a nice cloud of fuel vapor coming out of the throat before it dies. It also coats the carb throat in what looks to me like a mix of carbon and fuel since I can wipe it out with a shop towel and the residue is dark and smells like gas.

Now, I took quite a bit of time to read through the forum and try to make sure my cam is positioned correctly in relation to my crank and I have found the following.

Started by finding TDC with my homemade piston stop, “precisely” super glued a printed degree wheel to my rotor which you will see in a hot minute, and determined that my handiwork had fetched me a TDC at about 1° on the degree wheel (can’t adjust, super glue…) at which time I also took a picture of the cam pin position on the ATU side of the bike.

From here you can see it is NOT at 12 O’clock, marked out with my nifty earplug string and some duct tape setup, so I proceeded to move the crank in 5° increments (2.5° at the cam) to see where it became vertical.

So here is the picture at 5° ATDC

10° ATDC

15° ATDC

And finally 20° ATDC which is where, if I understand correctly, one tooth forward would be if I moved the cam

To me, the 5° ATDC seemed like the closest to vertical I could get but being that that is ~2.5 degrees at the cam I would think this would be okay right?

But after seeing this, and reading some more, I went out and bought a dial indicator and decided I was going to find out once and for all if that cam was in the right position. With the new tool, a harbor freight special, I took measurements and this is what I got for the intake lobe center.

While they aren’t perfect, 5/6 come out within a standard deviation and the only one that does not is the 104 measurement. The spec for the 256 cam intake as far as I can tell is 100°, so I am about 2° retarded at the crank or 1° at the cam right? This seems to tell me that I am in the right tooth position on the cam, but the only explanation I can convince myself of is that the “woofing” of the fuel vapor through the carb throat is from being a tooth off and having my intakes open/close late which keeps the valve open during compression.

Has anyone seen this before or have any thoughts on the matter? I am about at my wits end with this bike, but I love it too much to give up and buy anything else so I’m hoping someone/anyone was willing to read through all of that and hopefully tell me what I am missing?

Big thanks in advance,

GoldenEye

) roll it over while I watch the spark and strobe, hopefully that'll work... Also, I will grab a video of it tomorrow afternoon and see if I can't get the sound. If I had to try and explain it further, its like the motor is spinning backwards and kicking the vaporized fuel out of the carb throat like the firing is happening at a point where it can kick the piston back down and reverse the engine rotation? I might just buy new springs and cogs for the ATU since I shortened the springs last summer and they might just not be up to par anymore.

) roll it over while I watch the spark and strobe, hopefully that'll work... Also, I will grab a video of it tomorrow afternoon and see if I can't get the sound. If I had to try and explain it further, its like the motor is spinning backwards and kicking the vaporized fuel out of the carb throat like the firing is happening at a point where it can kick the piston back down and reverse the engine rotation? I might just buy new springs and cogs for the ATU since I shortened the springs last summer and they might just not be up to par anymore.