I'm a bit puzzled. As many of you know I have a 72 XS2. This is the start of the 2nd season on this engine since rebuilding the motor. Last year was 3000+ miles. This year I've already put all most 3000 on it. It has been running fine. Before leaving on a 1700 mile trip to the Ozarks a couple of weeks ago I took a quick compression test and got 120ish on each side. I thought there may be something wrong with the tester and didn't have time to go any further. Road it on the trip trip and it ran fine. No problem starting it, gas mileage was upper 40s, it pulled up hills just fine even with a 32 tooth sprocket on it and loaded down with extra weight from luggage. Since I got back I have been cleaning and doing some service on it. Well today I was finishing up a few thing on it and decided to check compression.

Now the puzzle. It would hardly get to 25 lbs on either cylinder. What the he!!. Checked the tester and could not find any problems. Definitely a compression problem, didn't even try to blow my finger off either plug hole. Head scratching time, all I've done to it since I road it into the shop is change oil and clean it. Hadn't even tried to start it. Off came the valve covers and checked valve clearance. I have been running 3 and 6. They may have been a little tight but I could move the rockers some with my fingers, definitely not zero lash. WTF. Loosened them up as much as my elephant foot adjuster allow. Rechecked compression 145. OK maybe they were tighter than I thought. Reset to 3 and 6. Still low, went to 4 and 7 better, 5 and 9 more better. 6 and 9 better but still low 125. Hmm. Earlier I had checked and adjusted the cam chain, it was a little loose. Decided to check cam timing. It's a little late. I don't think it's a tooth late. If it is it's been that way all along. One other thing the carbs are on a work bench waiting to go back on after being cleaned. Yes I took the paper towels out of the boots before checking compression.

I've been using the E-start to check the compression. With the valve adjusters backed off I got the 145 using the E-start. I think I'll get the battery back to full charge and think about it while it's charging.

Anyone have any thoughts

Now the puzzle. It would hardly get to 25 lbs on either cylinder. What the he!!. Checked the tester and could not find any problems. Definitely a compression problem, didn't even try to blow my finger off either plug hole. Head scratching time, all I've done to it since I road it into the shop is change oil and clean it. Hadn't even tried to start it. Off came the valve covers and checked valve clearance. I have been running 3 and 6. They may have been a little tight but I could move the rockers some with my fingers, definitely not zero lash. WTF. Loosened them up as much as my elephant foot adjuster allow. Rechecked compression 145. OK maybe they were tighter than I thought. Reset to 3 and 6. Still low, went to 4 and 7 better, 5 and 9 more better. 6 and 9 better but still low 125. Hmm. Earlier I had checked and adjusted the cam chain, it was a little loose. Decided to check cam timing. It's a little late. I don't think it's a tooth late. If it is it's been that way all along. One other thing the carbs are on a work bench waiting to go back on after being cleaned. Yes I took the paper towels out of the boots before checking compression.

I've been using the E-start to check the compression. With the valve adjusters backed off I got the 145 using the E-start. I think I'll get the battery back to full charge and think about it while it's charging.

Anyone have any thoughts

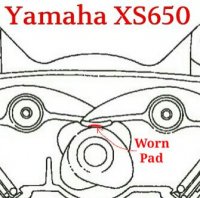

a "better" pic from before the trip.

a "better" pic from before the trip.