First timer

Rebuilding a 75b engine.

following the thread along with a pile of manuals.

have a couple of questions before I get ready to seal the cases.

Any input would be helpful.

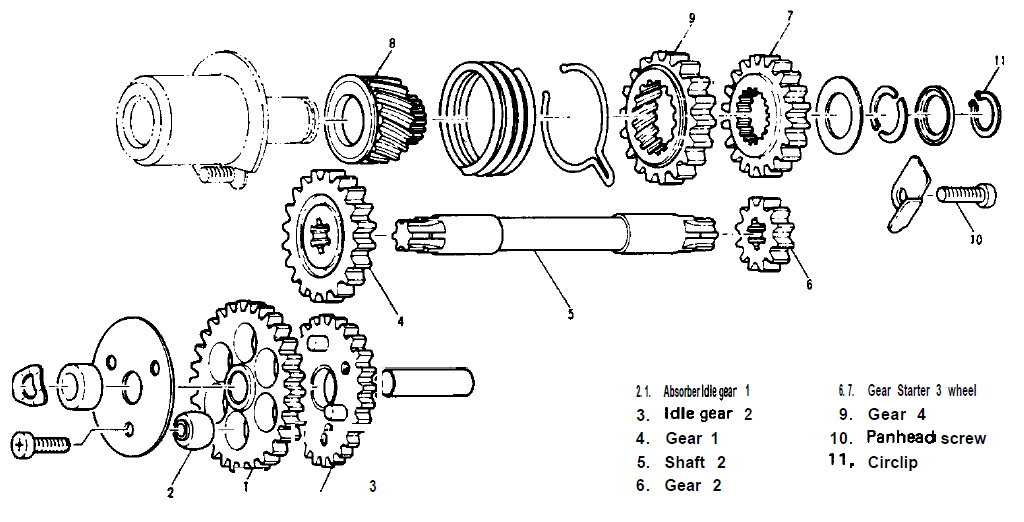

1. Does anything hold gear 4 on the shaft in the pic above? I looks like it could run up against the inside of the case but I don't see anything noted to hold it on?

2. Is there a best practices for checking the proper function of the gear box prior to closing things up. Once assembled I could rotate the shift drum by hand and run it through all of the gears and see the obvious changes. after installing the stopper plate and roller on the end of the drum as well as the spring and bolt for the neutral detent I can only switch it back and forth through two of the gears. Is this just a matter of the friction that will look better after go a couple more steps and get more leverage on it or do I need to undo it and work through this again?

3. In the Rob Gibson article on doing the rebuild ("Looking so go now for the chassis" page 28 picture 5) he refers to an oil seal on both ends of the crank -- Is this a typo? the line drawing does not show an oil seal on the left side?

4. Just to check so that I don't make a rooky mistake -- Yamabond on the oil seals during a rebuild? I don't see anything in the manuals about it. I see people using it when pressing them into existing engines but I don't see instruction during building?

Thanks in advance

Rebuilding a 75b engine.

following the thread along with a pile of manuals.

have a couple of questions before I get ready to seal the cases.

Any input would be helpful.

1. Does anything hold gear 4 on the shaft in the pic above? I looks like it could run up against the inside of the case but I don't see anything noted to hold it on?

2. Is there a best practices for checking the proper function of the gear box prior to closing things up. Once assembled I could rotate the shift drum by hand and run it through all of the gears and see the obvious changes. after installing the stopper plate and roller on the end of the drum as well as the spring and bolt for the neutral detent I can only switch it back and forth through two of the gears. Is this just a matter of the friction that will look better after go a couple more steps and get more leverage on it or do I need to undo it and work through this again?

3. In the Rob Gibson article on doing the rebuild ("Looking so go now for the chassis" page 28 picture 5) he refers to an oil seal on both ends of the crank -- Is this a typo? the line drawing does not show an oil seal on the left side?

4. Just to check so that I don't make a rooky mistake -- Yamabond on the oil seals during a rebuild? I don't see anything in the manuals about it. I see people using it when pressing them into existing engines but I don't see instruction during building?

Thanks in advance