I apologize for any repetitive questions/concerns ahead of time.

Hello everyone. On March 11th I am looking to undertake a tremendous project, stripping my 79 xs with the intention of overhauling the entire bike from the ground up. As a college student with limited resources and an ambitious but basic sense of mechanics I am devoted to overcome and triumph over this objective. In other words, I have two weeks to complete this project and prove to my folks that I can be responsible and actually finish a project that I started. Before I completely extinguish all hope you, as the reader, initially had for me, I am going to change the topic and tell you a little about myself. I am a full-time student, twenty-two years of age attending a college in upstate New York. I am a graduate of Wyoming technical institute, also known as Wyotech, graduated with a degree in Automotive technology - sadly three years have passed and my retention ability is not as good as I'd hoped. So with my Clymers manual at hand I spend the entire length of last summer dicking around with my first motorcycle. I purchased it for 800 dollars and devoted many sleepless nights to have it run, but it persisted to sing the same old song and shit on me continuously; I would fix one thing just to find out that another thing went. My summer quickly came to an end and I had to return to school in late August leaving the beast behind. Nearly everyday I think about what needs to be done and how do I go about doing so, repetitively writing out the same old list of needed parts. That is my intro in a nutshell.

I am looking for any help, in any form, to make this project a reality.

This is what I intend on doing, feel free to jump in with your two cents.

Firstly, I am looking to start off with rebuilding the top end with hopes of not touching the bottom nor the transmission. I am not familiar with problematic areas so any pointers as to what I should pay close attention to would be extremely useful. Because my funds are limited I prefer to salvage parts instead of purchasing new parts that I may not necessarily need. I am curious what powertrain modifications would be deemed worth it while I have access to the internals. I am completely open to suggestions. If I do choose to keep the stock components then I am simply going to clean the pistons, replace the rings, valve seals and machine the seats.

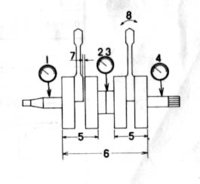

Secondly, I want to re-do the entire harness removing all of the accessory wiring and replacing the ignition with a pamco ignition unit. The previous owner installed a Boyer unit but feel that the unit is not working properly. It often gives off electrical feedback when the ignition key is in the on position. It sounds like a faint ticking sound in one of the cylinders. In addition, I feel as if the spark is abnormally weak. As far as the fuel, the previous owner installed VM 34s that I insist on retuning and need the most help in this category.

I am planning on running the VMs with XS Pods, stock motor, and a MAC 2-1 exhaust (MAC muffler). IF ANYONE HAS ANY INSIGHT ON WHAT JETS I NEED FOR THAT SET UP THAT WOULD BE A GREAT HELP.

Lastly, I am concerned with the frame and suspension. From my understanding the previous owner replaced the swing arm bushings and the steering bearings. What I want to do is improve the ride-ability and handling so I need some suggestions as to what parts I should consider in improving the dampening of the forks and rear shocks.

I may be leaving information and concerns out so feel free to provide feedback and ask as many questions as possible. I am relying highly on the XS community to please come together on this one and try to help a fellow brethren out. Before I forget, I also appreciate any advice for special tools and tips that I will require in preforming any task discussed. I want to start ordering the parts as soon as possible because time is of the essence.

I think that might be it.. so before I go I attached some photos

Hello everyone. On March 11th I am looking to undertake a tremendous project, stripping my 79 xs with the intention of overhauling the entire bike from the ground up. As a college student with limited resources and an ambitious but basic sense of mechanics I am devoted to overcome and triumph over this objective. In other words, I have two weeks to complete this project and prove to my folks that I can be responsible and actually finish a project that I started. Before I completely extinguish all hope you, as the reader, initially had for me, I am going to change the topic and tell you a little about myself. I am a full-time student, twenty-two years of age attending a college in upstate New York. I am a graduate of Wyoming technical institute, also known as Wyotech, graduated with a degree in Automotive technology - sadly three years have passed and my retention ability is not as good as I'd hoped. So with my Clymers manual at hand I spend the entire length of last summer dicking around with my first motorcycle. I purchased it for 800 dollars and devoted many sleepless nights to have it run, but it persisted to sing the same old song and shit on me continuously; I would fix one thing just to find out that another thing went. My summer quickly came to an end and I had to return to school in late August leaving the beast behind. Nearly everyday I think about what needs to be done and how do I go about doing so, repetitively writing out the same old list of needed parts. That is my intro in a nutshell.

I am looking for any help, in any form, to make this project a reality.

This is what I intend on doing, feel free to jump in with your two cents.

Firstly, I am looking to start off with rebuilding the top end with hopes of not touching the bottom nor the transmission. I am not familiar with problematic areas so any pointers as to what I should pay close attention to would be extremely useful. Because my funds are limited I prefer to salvage parts instead of purchasing new parts that I may not necessarily need. I am curious what powertrain modifications would be deemed worth it while I have access to the internals. I am completely open to suggestions. If I do choose to keep the stock components then I am simply going to clean the pistons, replace the rings, valve seals and machine the seats.

Secondly, I want to re-do the entire harness removing all of the accessory wiring and replacing the ignition with a pamco ignition unit. The previous owner installed a Boyer unit but feel that the unit is not working properly. It often gives off electrical feedback when the ignition key is in the on position. It sounds like a faint ticking sound in one of the cylinders. In addition, I feel as if the spark is abnormally weak. As far as the fuel, the previous owner installed VM 34s that I insist on retuning and need the most help in this category.

I am planning on running the VMs with XS Pods, stock motor, and a MAC 2-1 exhaust (MAC muffler). IF ANYONE HAS ANY INSIGHT ON WHAT JETS I NEED FOR THAT SET UP THAT WOULD BE A GREAT HELP.

Lastly, I am concerned with the frame and suspension. From my understanding the previous owner replaced the swing arm bushings and the steering bearings. What I want to do is improve the ride-ability and handling so I need some suggestions as to what parts I should consider in improving the dampening of the forks and rear shocks.

I may be leaving information and concerns out so feel free to provide feedback and ask as many questions as possible. I am relying highly on the XS community to please come together on this one and try to help a fellow brethren out. Before I forget, I also appreciate any advice for special tools and tips that I will require in preforming any task discussed. I want to start ordering the parts as soon as possible because time is of the essence.

I think that might be it.. so before I go I attached some photos