YammieBruh

XS650 Member

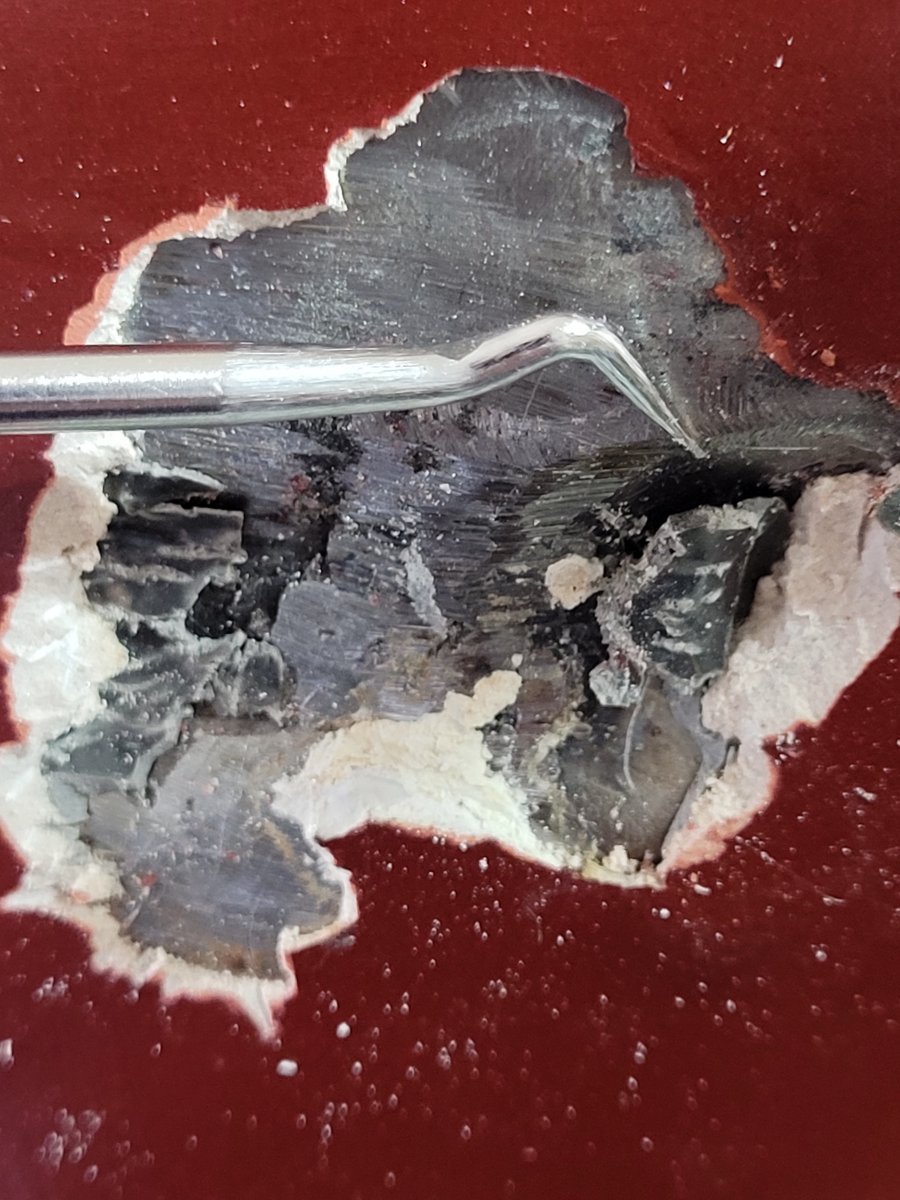

Hey everyone. So I've been trying to get this bike put back together to hopefully be able to ride this summer. After I added gas to the tank I started to notice some of the paint on the sides of the tank where the emblems used to be start to bubble. I was hoping this was a coincidence but decided to investigate. This is what I found. Looks like the usual handyman special with booger welds, but I've found a pin hole. My question is, since I don't have access to a welder is this worth trying to repair, I also think ther is a leak on a seam near the tank mount bolt that I was hoping to solder. Not sure if I should continue on or buy a new tank. Not really looking to get a used one since I might be in the same boat as this one especially for the prices some people want around my area.