I'll not go into the history of the bike here (or maybe I'll fill in the details at a later date), that's not my intent. Besides, if you know it, you'll already understand.

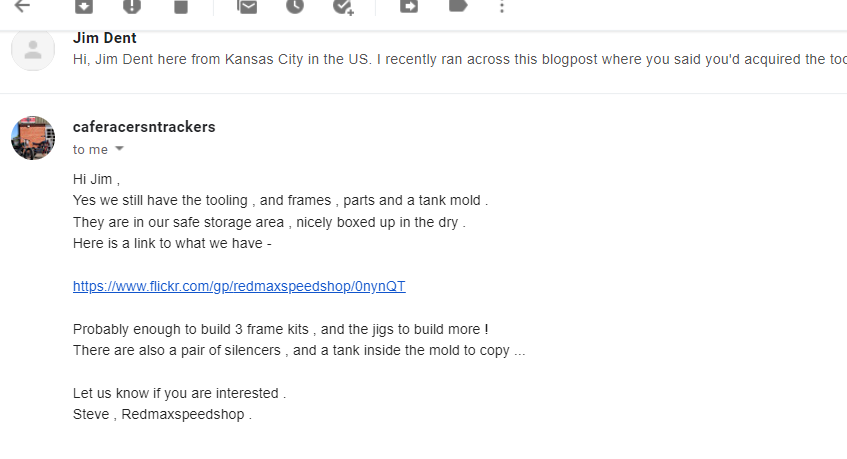

The tooling to build the frames and such still exist. They're in storage in Devon England, owned by the gentlemen at Redmax Speed Shop. I contacted them and Steve responded with the following email...

So... anyone who's ever wanted one, there you go. Give him a shout and see what he want's for the bits to build one.

Here, there's 43 pics here.... enjoy some XS650 porn....

The tooling to build the frames and such still exist. They're in storage in Devon England, owned by the gentlemen at Redmax Speed Shop. I contacted them and Steve responded with the following email...

So... anyone who's ever wanted one, there you go. Give him a shout and see what he want's for the bits to build one.

Here, there's 43 pics here.... enjoy some XS650 porn....

Last edited: