Edit: this project ended in failure, see the results at the bottom of the page.

The other day, I took my XS2 out for its first shakedown ride after rebuilding the top end, and also my first ride with my freshly painted gas tank. My first stop was to fill up the gas tank, after riding for a while I noticed a thin stream of gas trickling down the side of the tank. Oh no! This will never do! Fortunately the paint proved quite tough, I wiped it off and when I got home I washed and waxed the tank, and all is well.

Fortunately the paint proved quite tough, I wiped it off and when I got home I washed and waxed the tank, and all is well.

Which brings me to the point of this article,

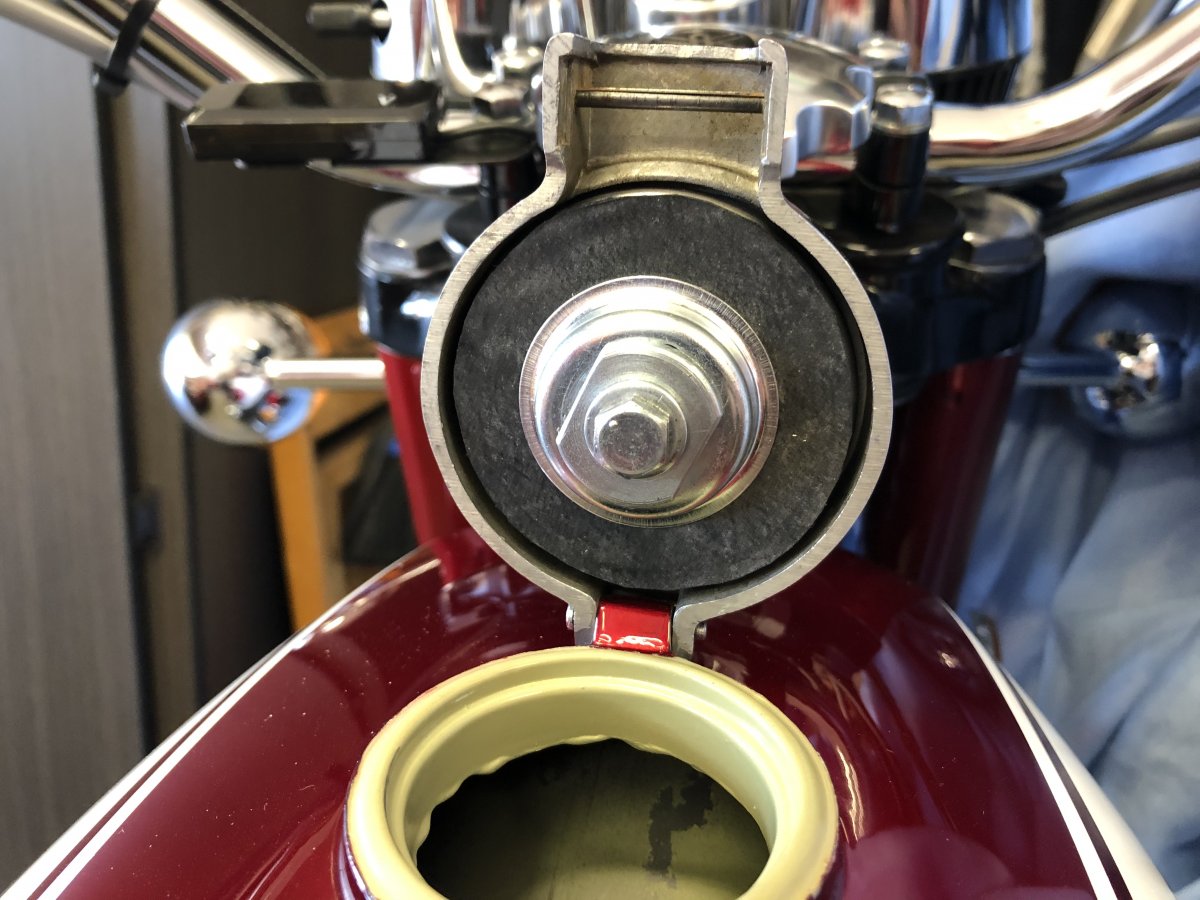

This was the culprit, the stock gasket was cracked,

I had a replacement from Mikes XS on hand, but it is noticeably smaller, 5mm to be exact. It’s just too small, when I closed the cap, instead of sealing, it was squeezing down inside the neck of the filler.

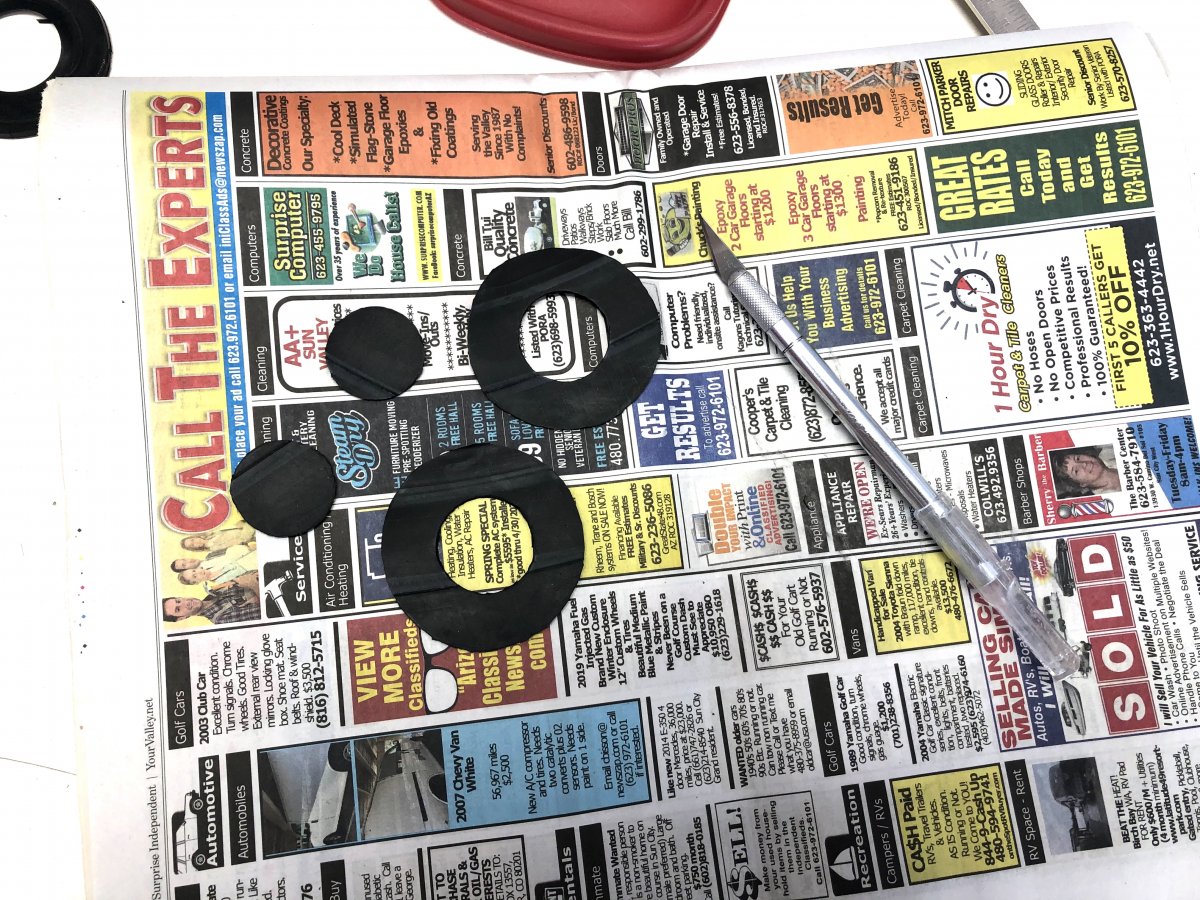

They are not available from Yamaha, and I found a NOS on EBay. But I thought I’d take a crack at fabbing one up. I was looking for rubber sheets 2mm thick on EBay but mostly they come from China and I didn’t feel like waiting. So....what to do? I have some old inner tube scraps that I keep for all sorts of stuff, they are only half the thickness I need, so I’m going to cut two of them and laminate them. I traced out a pattern on the scraps.

After cutting them out, I cleaned them with acetone and I spread a thin layer of Black RTV silicone on each piece , let them get tacky then placed the sticky sides together, laid it on my bench and placed a block of wood and a heavy weight on top and left it overnight. The results......

The new one is now the same dimensions as a NOS one

With one small difference, my homemade one is .5 mm thicker

It now reaches all the way to the edge of the cap, it closes like it should and fits much better. And it cost me nothing.

Credit for this idea goes to @TwoManyXS1Bs , who bought the proper 2mm sheet of rubber and machined out a perfectly cut factory replica.....of course! I’m just a cheap hack working with scraps and scissors.

I’m just a cheap hack working with scraps and scissors.

The other day, I took my XS2 out for its first shakedown ride after rebuilding the top end, and also my first ride with my freshly painted gas tank. My first stop was to fill up the gas tank, after riding for a while I noticed a thin stream of gas trickling down the side of the tank. Oh no! This will never do!

Fortunately the paint proved quite tough, I wiped it off and when I got home I washed and waxed the tank, and all is well.

Fortunately the paint proved quite tough, I wiped it off and when I got home I washed and waxed the tank, and all is well.Which brings me to the point of this article,

This was the culprit, the stock gasket was cracked,

I had a replacement from Mikes XS on hand, but it is noticeably smaller, 5mm to be exact. It’s just too small, when I closed the cap, instead of sealing, it was squeezing down inside the neck of the filler.

They are not available from Yamaha, and I found a NOS on EBay. But I thought I’d take a crack at fabbing one up. I was looking for rubber sheets 2mm thick on EBay but mostly they come from China and I didn’t feel like waiting. So....what to do? I have some old inner tube scraps that I keep for all sorts of stuff, they are only half the thickness I need, so I’m going to cut two of them and laminate them. I traced out a pattern on the scraps.

After cutting them out, I cleaned them with acetone and I spread a thin layer of Black RTV silicone on each piece , let them get tacky then placed the sticky sides together, laid it on my bench and placed a block of wood and a heavy weight on top and left it overnight. The results......

The new one is now the same dimensions as a NOS one

With one small difference, my homemade one is .5 mm thicker

It now reaches all the way to the edge of the cap, it closes like it should and fits much better. And it cost me nothing.

Credit for this idea goes to @TwoManyXS1Bs , who bought the proper 2mm sheet of rubber and machined out a perfectly cut factory replica.....of course!

I’m just a cheap hack working with scraps and scissors.

I’m just a cheap hack working with scraps and scissors.

Last edited: