View attachment 183292 With winter upon us and Covid restrictions, what better to do than tear the bike apart. Since I purchased the bike I’ve always questioned the location / accuracy of the timing marks that were placed by the po. Anyway, an excuse to buy a rotor puller for the installed PMA. Bought a Motion Pro puller and was impressed by the quality of the tool. I pulled the rotor (hope I’m calling it by the correct name) and was pleased to see the key was still in the crank to positively locate the rotor on the shaft.

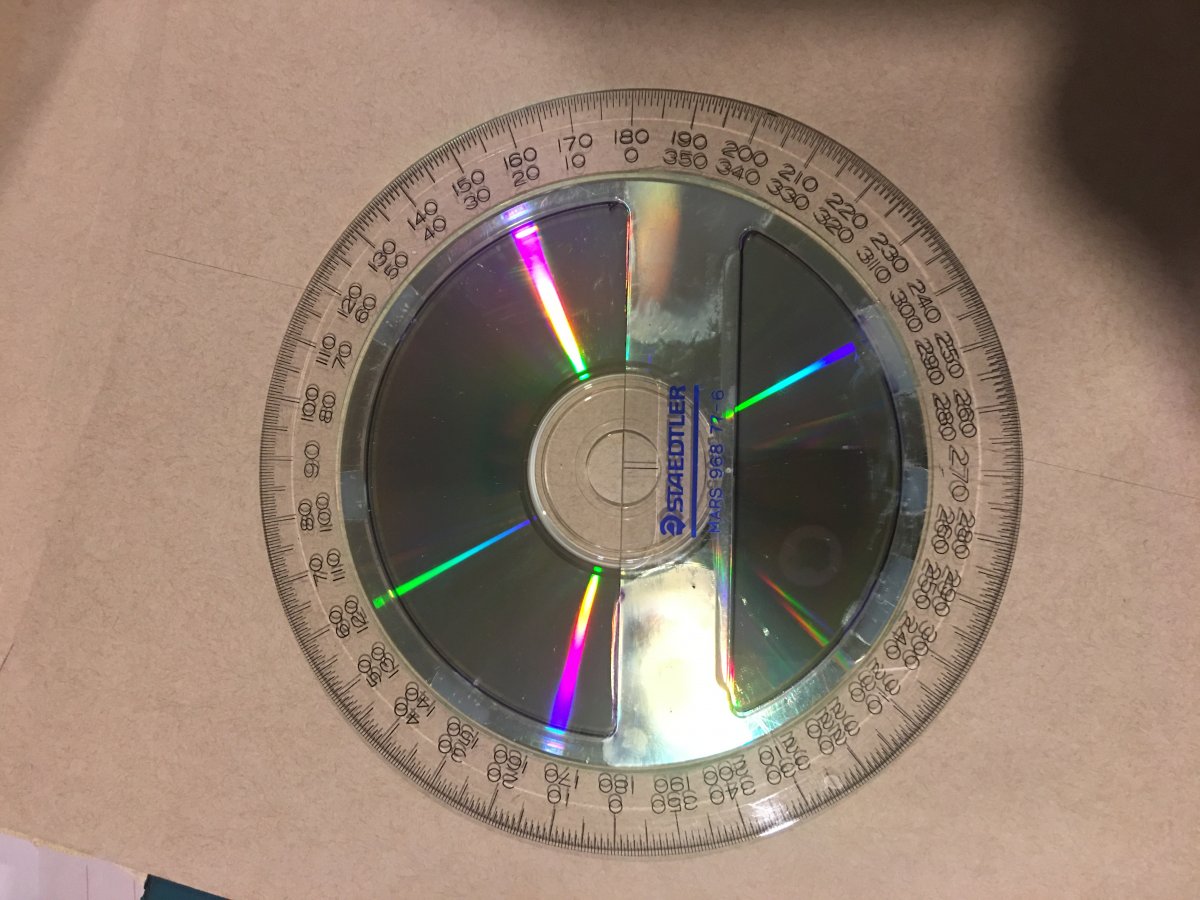

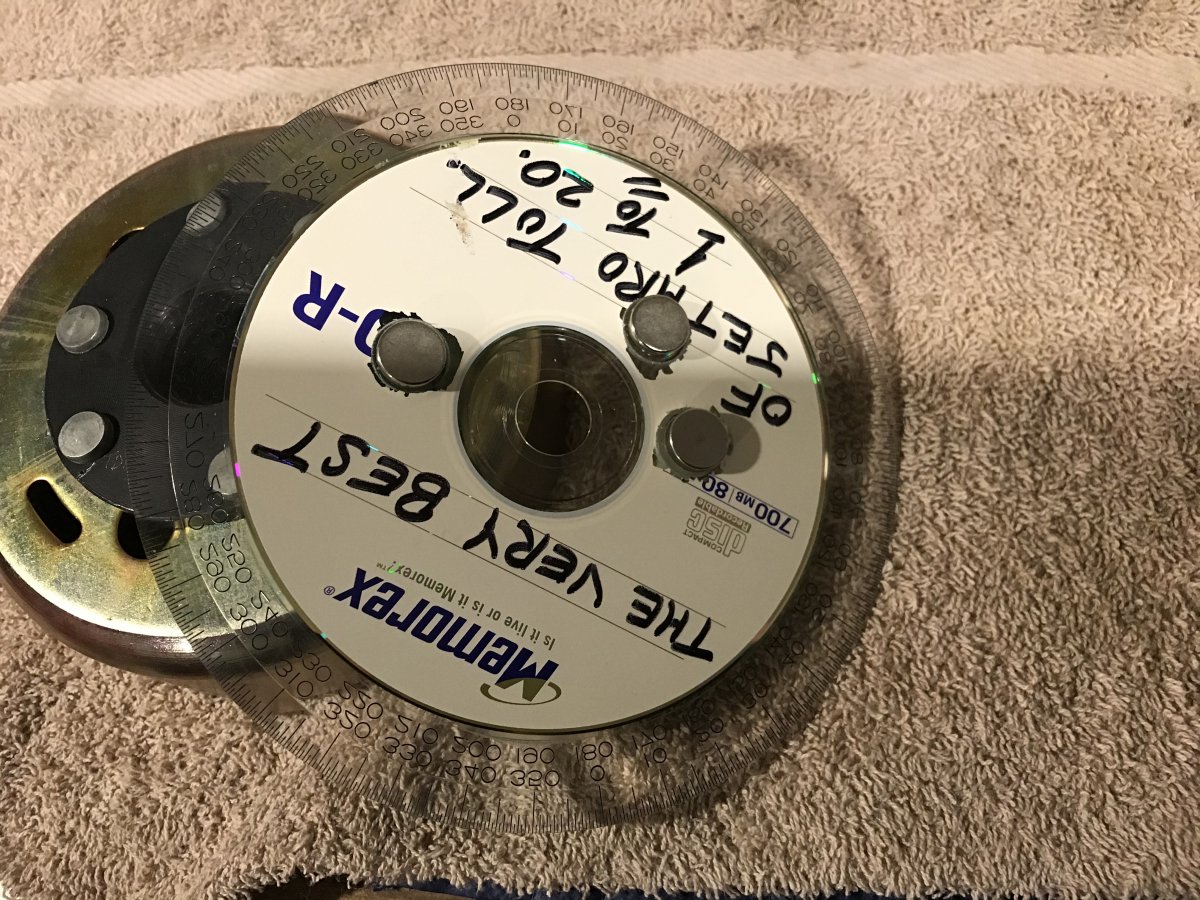

To properly find TDC I needed a timing degree wheel. Looked on line and decided (cheaped out) I should make something up on my own, since I would most likely never use it again. Looked in my toolbox and found an old 6” Staedtler Mars protractor that I would probably never use again (but know that now that I’ve hacked it up I’ll need it tomorrow . Decided to mount it to a CD and couldn’t find any new ones in the house, so poor Jethro Tull was sacrificed. A bit of Krazy glue, 3 rare earth magnets and my makeshift degree wheel was born. Will try it out tomorrow.

. Decided to mount it to a CD and couldn’t find any new ones in the house, so poor Jethro Tull was sacrificed. A bit of Krazy glue, 3 rare earth magnets and my makeshift degree wheel was born. Will try it out tomorrow.

Maybe if I leave it on the rotor and shoot it with a laser I’ll be able to listen to Jethro on the road

We all like pics so here we go.

To properly find TDC I needed a timing degree wheel. Looked on line and decided (cheaped out) I should make something up on my own, since I would most likely never use it again. Looked in my toolbox and found an old 6” Staedtler Mars protractor that I would probably never use again (but know that now that I’ve hacked it up I’ll need it tomorrow

Maybe if I leave it on the rotor and shoot it with a laser I’ll be able to listen to Jethro on the road

We all like pics so here we go.

Last edited: