This is part of my XS2 restoration that I’m doing. More on that here ,

http://www.xs650.com/threads/mailman’s-xs2-a-sympathetic-restoration.51520/

I know a lot of you have done this, probably multiple times, but if you never have, it’s sometimes hard to find good information on how to do it. So with that in mind I’m going to write a photo intensive little how to. Others might have different methods but this is how I did it. Let’s begin.....

My original seat was rotted and ripped, the foam was crumbling and useless, so this was a total rebuild. I have looked back through forum searches and found that at various times replacement seat foams have been available through various vendors. As of this time I am aware of only one resource, HVCycle.

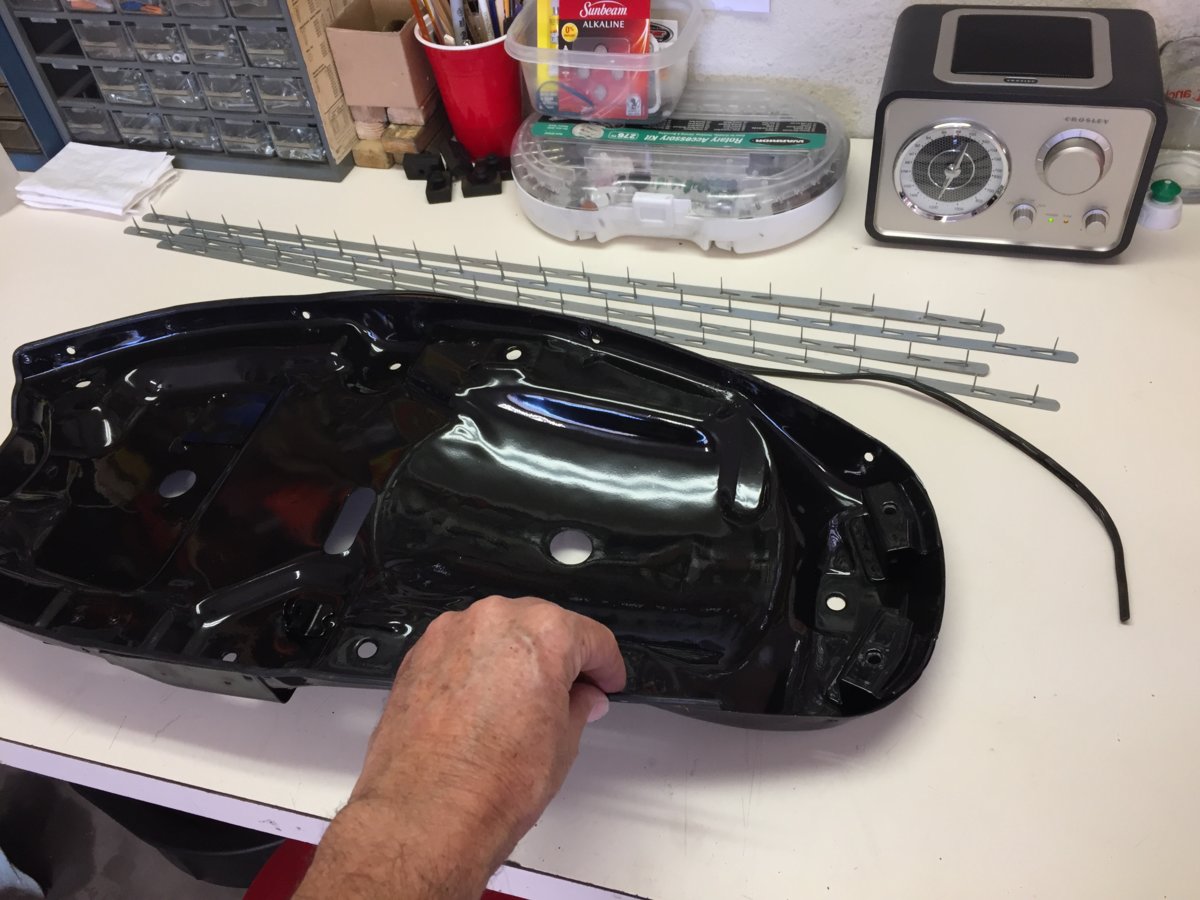

The first thing I did was strip everything down and sand and paint the pan. For this project I bought a new seat foam, generic upholstery tack strips from eBay , and a new seat cover.

First glue the rubber bead that was removed earlier, back on to the edge of the seat pan, this keeps the metal edge from cutting the vinyl. In this photo you can see the tack strips that I will be cutting to fit and attaching with pop rivets.

Attach the tack strips. Note: my seat pan is an early model, the original seat cover had a heavy cord stitched into the bottom edge, which was held in place by clips. I removed the clips because my seat cover is an oversized cut to fit at the bottom edge. Later model seat pans have diamond shape teeth to hold the seat cover. Most of the time they can be reused. Another source for tack strips is HVCycle.

I went back around after this with two small hammers and flattened the pop rivets. Next step, and I didn’t photograph this because I had to move fast, spray adhesive to the top side of the pan where the foam will rest and the bottom side of the foam and quickly put the two together. Buy a spray adhesive that has foam listed on its uses. Mine said to assemble foam while still wet and it dries fast! So...foam is on and I used clothes pins to hold the edges while the adhesive dried. Also you will see the painters tape with arrows, those are to locate the holes in the pan for my trim molding that will be covered up later.

At this point my seat cover was ready to go, and by that I mean I had it opened up and lying on my driveway on a 100 degree Arizona day. The point is it helps if the seat cover has been heated to make it pliable and so it can be stretched. I have heard of some people throwing it in a clothes dryer to warm it, for me I just used the sun. I placed my seat pan and foam on top of a bucket and began working the seat cover down onto the seat, I used clothes pins to hold it in place.

Once I got the general shape of it right, I removed the bucket, flipped it over and began really attaching it. It was impossible for me to photograph this part because it required two hands, but you want the seat cover to be stretched tight, so with the seat upside down, press the seat down to compress the foam and at the same time pull the vinyl evenly over the edge of the pan and start poking the tack strip through the vinyl. I started at the front, then back then one side middle, then the other side middle, kinda like torquing down a head. Keep moving back and forth like that. At this point none of the barbs have been bent down, save that for last in case you want to reposition. Try to keep the cover smooth on the sides with no angled pulls, no wrinkles, keep turning the seat over and look at it to check your progress and make sure you’re keeping it straight. When you are where you like it, now start folding down the barbs. On my seat cover this is the point where I trimmed off the excess.

The front corners may need a little custom fitting. On mine, I folded the corners as neatly as possible and used super glue and clamps to hold it. I will be using super glue more before I’m done.

A WARNING HERE....be careful using super glue. Use it sparingly, it will squeeze out and without realizing it stick your fingers to your seat and if you get it on the seat where it shows it WILL mar your finish. So use it or don’t, your choice, but be careful with it if you do.

I went all the way around and anywhere the seat cover looked a little loose, I picked up the edge, put a drop of super glue and clamped it.

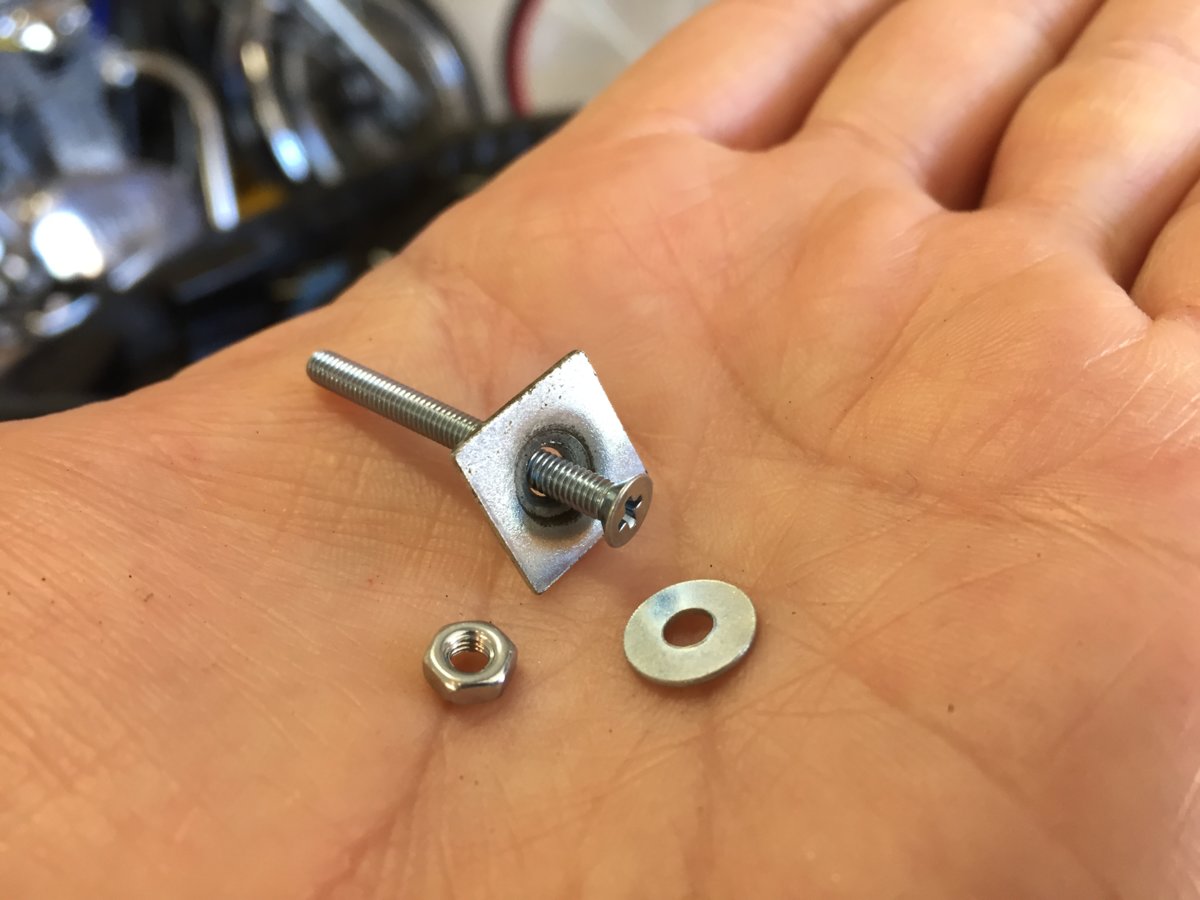

Ok, the seat cover is on and I want to reattach my seat trim that I took off in the beginning. The original trim hardware looked like long skinny machine screw that had a domed rivet head. I replaced it with countersunk machine screws from the hardware store. I reused the square track holders.

Now you can see why I marked where the trim bolt holes are, they would’ve been difficult to find otherwise.

Everything positioned, start fitting the trim back on and start tightening them down. I had to grab the end of the screws with pliers and pull them so that I could tighten the nuts down.

I used blue thread locker when it got up close to being tight. So everything’s been tightened , originally the factory just hammered these screws over sideways. I cut them off, leaving some thread exposed and tapped the end of the screws with a hammer to kinda roll the threads over a little.

And the end results.

About the hand rail, that’s a story for my XS2 build thread!

Until next time

Bob

http://www.xs650.com/threads/mailman’s-xs2-a-sympathetic-restoration.51520/

I know a lot of you have done this, probably multiple times, but if you never have, it’s sometimes hard to find good information on how to do it. So with that in mind I’m going to write a photo intensive little how to. Others might have different methods but this is how I did it. Let’s begin.....

My original seat was rotted and ripped, the foam was crumbling and useless, so this was a total rebuild. I have looked back through forum searches and found that at various times replacement seat foams have been available through various vendors. As of this time I am aware of only one resource, HVCycle.

The first thing I did was strip everything down and sand and paint the pan. For this project I bought a new seat foam, generic upholstery tack strips from eBay , and a new seat cover.

First glue the rubber bead that was removed earlier, back on to the edge of the seat pan, this keeps the metal edge from cutting the vinyl. In this photo you can see the tack strips that I will be cutting to fit and attaching with pop rivets.

Attach the tack strips. Note: my seat pan is an early model, the original seat cover had a heavy cord stitched into the bottom edge, which was held in place by clips. I removed the clips because my seat cover is an oversized cut to fit at the bottom edge. Later model seat pans have diamond shape teeth to hold the seat cover. Most of the time they can be reused. Another source for tack strips is HVCycle.

I went back around after this with two small hammers and flattened the pop rivets. Next step, and I didn’t photograph this because I had to move fast, spray adhesive to the top side of the pan where the foam will rest and the bottom side of the foam and quickly put the two together. Buy a spray adhesive that has foam listed on its uses. Mine said to assemble foam while still wet and it dries fast! So...foam is on and I used clothes pins to hold the edges while the adhesive dried. Also you will see the painters tape with arrows, those are to locate the holes in the pan for my trim molding that will be covered up later.

At this point my seat cover was ready to go, and by that I mean I had it opened up and lying on my driveway on a 100 degree Arizona day. The point is it helps if the seat cover has been heated to make it pliable and so it can be stretched. I have heard of some people throwing it in a clothes dryer to warm it, for me I just used the sun. I placed my seat pan and foam on top of a bucket and began working the seat cover down onto the seat, I used clothes pins to hold it in place.

Once I got the general shape of it right, I removed the bucket, flipped it over and began really attaching it. It was impossible for me to photograph this part because it required two hands, but you want the seat cover to be stretched tight, so with the seat upside down, press the seat down to compress the foam and at the same time pull the vinyl evenly over the edge of the pan and start poking the tack strip through the vinyl. I started at the front, then back then one side middle, then the other side middle, kinda like torquing down a head. Keep moving back and forth like that. At this point none of the barbs have been bent down, save that for last in case you want to reposition. Try to keep the cover smooth on the sides with no angled pulls, no wrinkles, keep turning the seat over and look at it to check your progress and make sure you’re keeping it straight. When you are where you like it, now start folding down the barbs. On my seat cover this is the point where I trimmed off the excess.

The front corners may need a little custom fitting. On mine, I folded the corners as neatly as possible and used super glue and clamps to hold it. I will be using super glue more before I’m done.

A WARNING HERE....be careful using super glue. Use it sparingly, it will squeeze out and without realizing it stick your fingers to your seat and if you get it on the seat where it shows it WILL mar your finish. So use it or don’t, your choice, but be careful with it if you do.

I went all the way around and anywhere the seat cover looked a little loose, I picked up the edge, put a drop of super glue and clamped it.

Ok, the seat cover is on and I want to reattach my seat trim that I took off in the beginning. The original trim hardware looked like long skinny machine screw that had a domed rivet head. I replaced it with countersunk machine screws from the hardware store. I reused the square track holders.

Now you can see why I marked where the trim bolt holes are, they would’ve been difficult to find otherwise.

Everything positioned, start fitting the trim back on and start tightening them down. I had to grab the end of the screws with pliers and pull them so that I could tighten the nuts down.

I used blue thread locker when it got up close to being tight. So everything’s been tightened , originally the factory just hammered these screws over sideways. I cut them off, leaving some thread exposed and tapped the end of the screws with a hammer to kinda roll the threads over a little.

And the end results.

About the hand rail, that’s a story for my XS2 build thread!

Until next time

Bob