I've found you can't really set the spoke tension by pitch, especially on a used rim. Yes, you want the spokes tight enough so they "ring" when tapped (as opposed to a dull thud indicating they're loose) but if you set them all to the same pitch, the wheel won't be true. Just make sure they all "ring" to some extent. You can tap them with the plastic handle of a screwdriver or "strum" them like a harp. When going around the wheel initially, I strum them. To zero in more precisely and hear the pitch better, I use the screwdriver handle.

I'm sure you've read some suggest you can true a wheel just mounted on the bike using a pointer made from a coat hanger. You could ride a Honda 90 around the world too. I don't recommend either, lol. A dedicated wheel stand is best. Expensive to buy but simple and cheap to make if you have access to a welder. I can provide you some simple plans if you like.

OK, I start by setting the stand up where I'm going to do the job and leveling the axle in the stand. The stand will remain where it is now for the entire job. If I move it to another location, I will need to re-check the axle level .....

Next, the wheel needs to be shimmed snug in the stand so it can't slide side to side. If it could, you might never get it trued .....

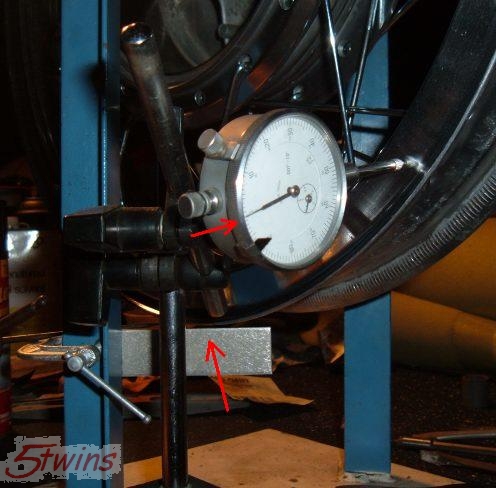

For true, I use a dial gauge and magnetic base holder. These are just HF items and the complete set-up can be had for less than $20 on sale. For the up and down run-out, I just use a pointer. The edge of the rim or the inner surface where the tire bead seats is usually too rough for a dial gauge .....

The spec for both true and run-out is 2mm. That's about .080". It's usually pretty easy to true a rim within .010". For the run-out, I just get it as close as my eyes staring at a pointer will allow. There will always be a spot on the rim where it's welded that will make the gauge jump .010"-.015". You pretty much just ignore that because there's not much you can do about it anyway .....

The procedure is pretty simple. You tighten spokes running to the left flange, loosen the ones next to them running to the right flange, to pull the rim left, do the opposite to pull it right. For the up-down run-out, tighten or loosen 4 to 6 spokes in a row opposite the high/low spot, do the opposite of that to the spokes at the high/low spot.

You will need to know your rim offset before you start. I measure and record that first before disassembling the old wheel. I use a straight edge and measure from the drum to rim edge or disc mount (disc if installed) to rim edge .....

On a newly laced rim, I start by snugging all the spokes equally. Then I find (or make by adjusting spokes) a spot on the rim that matches the offset. I zero the gauge there and work the rest of the rim to match that spot. I do the up-down run-out first before the true, keeping an eye on it for any major changes while I true.