Model differences

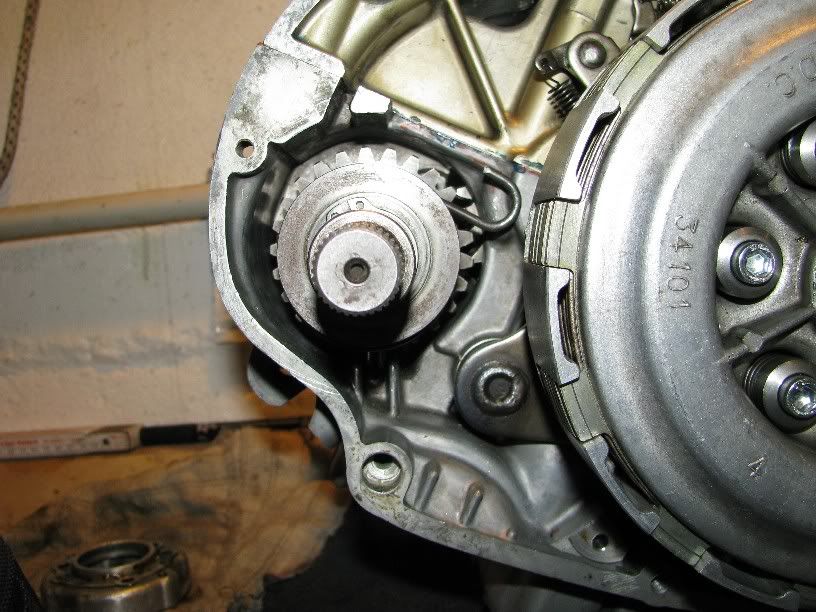

- early..XS1,B and some F had a 26 tooth gear and smaller ended shaft..

early shaft

later shaft

25T gear

- XS1, B also used a thrust bearing between the seal and the spring guide instead of a washer and had no circlip on the shaft to hold the mechanism in place

- here in europe there were also 3 different kickstart levers and relevant bosses..see below

Fitting the mechanism

- …easier with 3 hands or 2 people

How does it work?

- The gear, early 26 Teeth-later 25 Teeth, which meshes into the gearbox gear, moves along the kickstart shaft on a tight spiral spline…the kick clip prevents the gear from rotating…when the kickstart lever is depressed, the gear slides along the shaft as the shaft rotates, meshes into the gearbox gear and "voila"

kick clip

mechanism

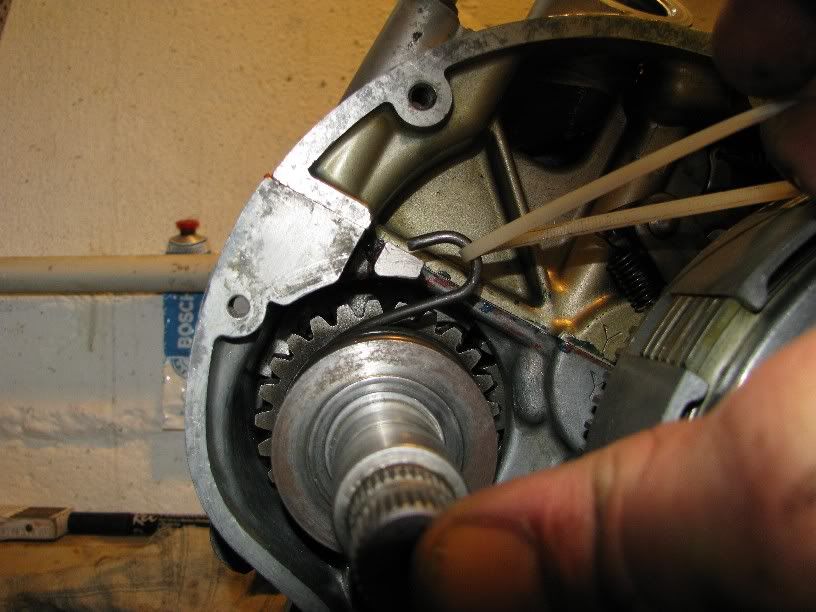

- The kickstart stop prevents the shaft from continuing and must be so positioned that the shaft is to the left of a moulding in the case and can rotate about 90° counterclockwise…when the stop is on the wrong side you cant move the kickstart...you can see the moulding in this pic under the spring hook

Common problems

- there are several common problems experienced with the kickstart, all manifest themselves with a non-returning kick mechanism or with no kick pressure

- broken hook on the spiral spring, either end…replace...in this pic you can see both ends

- broken spiral spring anchor point…file broken base flat, centrepunch, drill 6mm hole about 35mm deep, tap a thread into it, insert and loctite a 50mm bolt-the spring can now hook over this...here you can see the hook fitted over the anchor

- worn or broken kick clip-these don’t successfully retension and need to be replaced…usually this causes you to kick through with no pressure…when removing or replacing this clip, don’t pull it out or push it into the groove or you will lose the pretension…come in from the side, locate one side then the other..here clip fitted

- clip and starter holders found in sump...make sure they are properly fitted

Ball bearing stuck

Not much you can do here except use a lathe...

- turn the boss until its cylindrical ( - 0,5mm).

- open the lever hole (+0,5mm)

- fabricate a Steel or Bronze bush with ~1mm walls, press over the boss and bore the bearing hole

There are, i think, 3 different kickstart levers…

- the straight version, commonly found on american models and early XS1-XS2..when turned in it’s vertical and could theoretically be relocated on the spline so that it sits in front of the sidecover instead of the right hand carb

you see these too

- the early european version from TXA-XSE, heavier than the later version, has a slight angle half way between the boss and the kick rubber..it must sit so the rubber is parallel to the right hand carb or it contacts the sidecover

- more or less the same as #2 except it’s thinner and lighter, from XS-SE 79 on… when folded in the rubber is inclined toward the right hand carb holder

- the 18mm boss repair kit for the 79 and earlier

- the 15mm boss repair kit for 80 on

- the SR500 kickstart also fits the XS spline, and is shorter-about 2cm, and much more angled-gives better clearance for aftermarket pipes and rear sets etc

- you can shorten the originals if you wish, better to remove a section as high as possible, bore both faces min 25mm and press fit a hard material (C60, C45)…shieldgas weld and smooth so that there is no notch effect

- there are shorter yamaha kickstarters available...1JN-15610-00…length-175mm cf original-210mm

- removing the kickstart altogether?

Parts list

- early..XS1,B and some F had a 26 tooth gear and smaller ended shaft..

early shaft

later shaft

25T gear

- XS1, B also used a thrust bearing between the seal and the spring guide instead of a washer and had no circlip on the shaft to hold the mechanism in place

- here in europe there were also 3 different kickstart levers and relevant bosses..see below

Fitting the mechanism

- …easier with 3 hands or 2 people

One way

- fit shaft spigot into the case

- mount the kickstart lever

- rotate the kick clip into the shaft …don’t slide it in, you will remove the prestressing and you wont be able to successfully get it back

- hook the spiral spring nose over the case anchor point

- push on the shaft and rotate the kickstart lever to tension the spiral spring

- when you reach the point where the kick stop finds its place-KLICK-and the shaft will go fully into positionAnother way

...hattip stefan

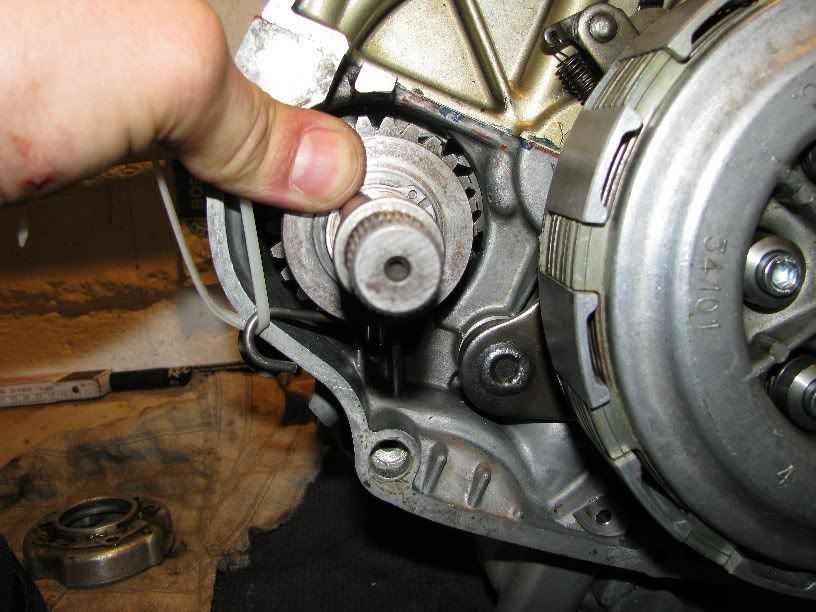

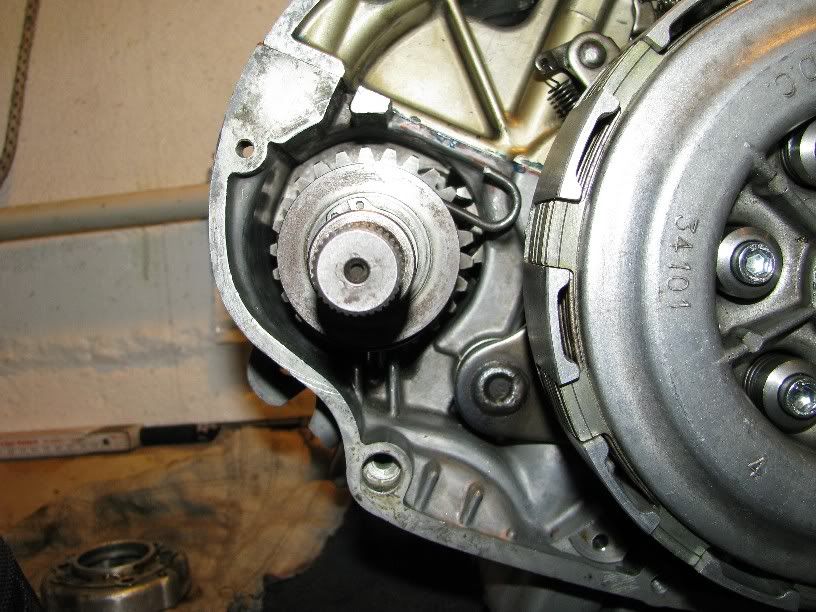

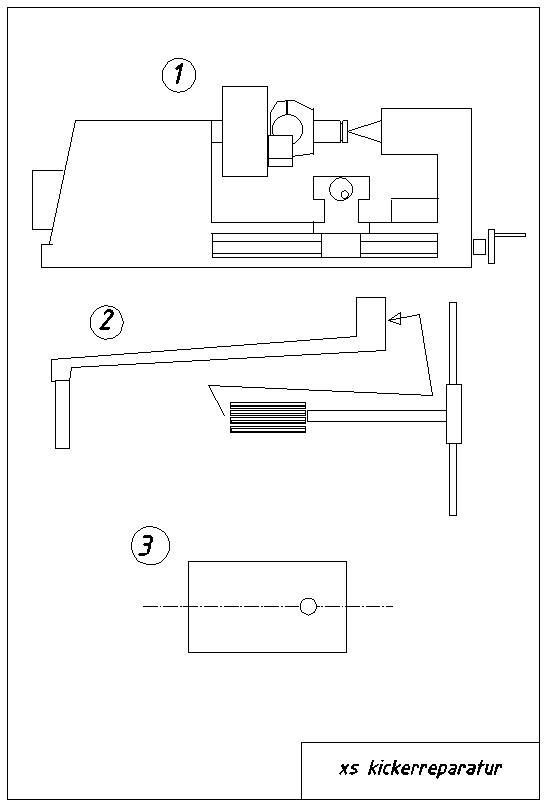

- fit the kickstarter, complete with kick clip, in the full kick position, return spiral spring is "at rest"..(pic 1)

- tie a cable tie to the spring hook and rotate clockwise to tension

- holding the tension, pull the shaft slightly out of the housing without scratching the gasket surface to get the spring hook over the anchor point…keep inward pressure on the complete mechanism so it doesn’t fly apart.. (pic 2)...make sure the stop is to the left of the moulding at 01.00

- fit the hook over the anchor point and push mechanism into place.. (pic 3)How does it work?

- The gear, early 26 Teeth-later 25 Teeth, which meshes into the gearbox gear, moves along the kickstart shaft on a tight spiral spline…the kick clip prevents the gear from rotating…when the kickstart lever is depressed, the gear slides along the shaft as the shaft rotates, meshes into the gearbox gear and "voila"

kick clip

mechanism

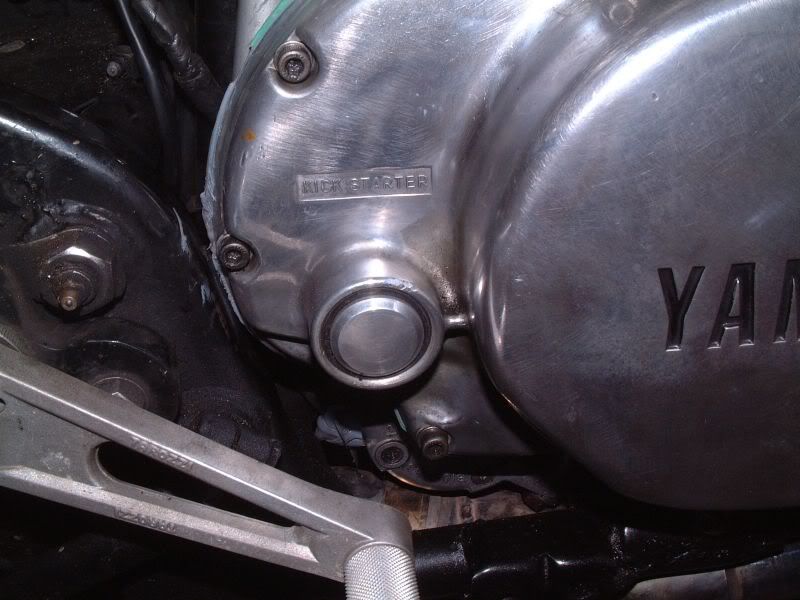

- The kickstart stop prevents the shaft from continuing and must be so positioned that the shaft is to the left of a moulding in the case and can rotate about 90° counterclockwise…when the stop is on the wrong side you cant move the kickstart...you can see the moulding in this pic under the spring hook

Common problems

- there are several common problems experienced with the kickstart, all manifest themselves with a non-returning kick mechanism or with no kick pressure

- broken hook on the spiral spring, either end…replace...in this pic you can see both ends

- broken spiral spring anchor point…file broken base flat, centrepunch, drill 6mm hole about 35mm deep, tap a thread into it, insert and loctite a 50mm bolt-the spring can now hook over this...here you can see the hook fitted over the anchor

- worn or broken kick clip-these don’t successfully retension and need to be replaced…usually this causes you to kick through with no pressure…when removing or replacing this clip, don’t pull it out or push it into the groove or you will lose the pretension…come in from the side, locate one side then the other..here clip fitted

- clip and starter holders found in sump...make sure they are properly fitted

Ball bearing stuck

Not much you can do here except use a lathe...

- turn the boss until its cylindrical ( - 0,5mm).

- open the lever hole (+0,5mm)

- fabricate a Steel or Bronze bush with ~1mm walls, press over the boss and bore the bearing hole

There are, i think, 3 different kickstart levers…

- the straight version, commonly found on american models and early XS1-XS2..when turned in it’s vertical and could theoretically be relocated on the spline so that it sits in front of the sidecover instead of the right hand carb

you see these too

- the early european version from TXA-XSE, heavier than the later version, has a slight angle half way between the boss and the kick rubber..it must sit so the rubber is parallel to the right hand carb or it contacts the sidecover

- more or less the same as #2 except it’s thinner and lighter, from XS-SE 79 on… when folded in the rubber is inclined toward the right hand carb holder

- the 18mm boss repair kit for the 79 and earlier

- the 15mm boss repair kit for 80 on

- the SR500 kickstart also fits the XS spline, and is shorter-about 2cm, and much more angled-gives better clearance for aftermarket pipes and rear sets etc

- you can shorten the originals if you wish, better to remove a section as high as possible, bore both faces min 25mm and press fit a hard material (C60, C45)…shieldgas weld and smooth so that there is no notch effect

- there are shorter yamaha kickstarters available...1JN-15610-00…length-175mm cf original-210mm

- removing the kickstart altogether?

Parts list

Attachments

Last edited: