rhkansas

XS650 Enthusiast

Part one: Getting to the Bottom of Things..

Please note that this modification is for the late model (1980) and later special and special 2 models with the lift off saddle. I'm also not the greatest at documenting projects as I go along - tend to get involved in the work and forget all about the camera on the workbench - I apologize in advance for any lacking detail in the accompanying photos.

This modification will lower the seating position, and requires sheet metal cutting, forming and welding - but nothing too complicated. There is also some considerable foam work - still nothing terribly complicated. The end result will be a saddle much more comfortable than the stock configuration with support in the right places.

The first order of business is to correct the issue in the foundation of the seat pan itself. The stock pan has a glaring issue in its construction that makes for an uncomfortable seat as the foam is compressed and you're left sitting on some very uncomfortable pressure points. Here's the starting point - Seat in need of rebuild - cover torn and foam beginning to break down.

Carefully bend out the holding teeth and remove the cover - bend them only enough to get the old cover out from under - I have had most success at bending no more that 45 degrees or so...

Remove the seat cover and the old foam. Try to remove the foam in one piece, particularly the pillion portion, as it will be re-used. The bare pan now exposes the problem area that needs to be addressed.

Note the raised center part - this is what you're sitting on when the foam compresses - about 6 inches wide and slanted forward - it will make your backside sore in a short time.

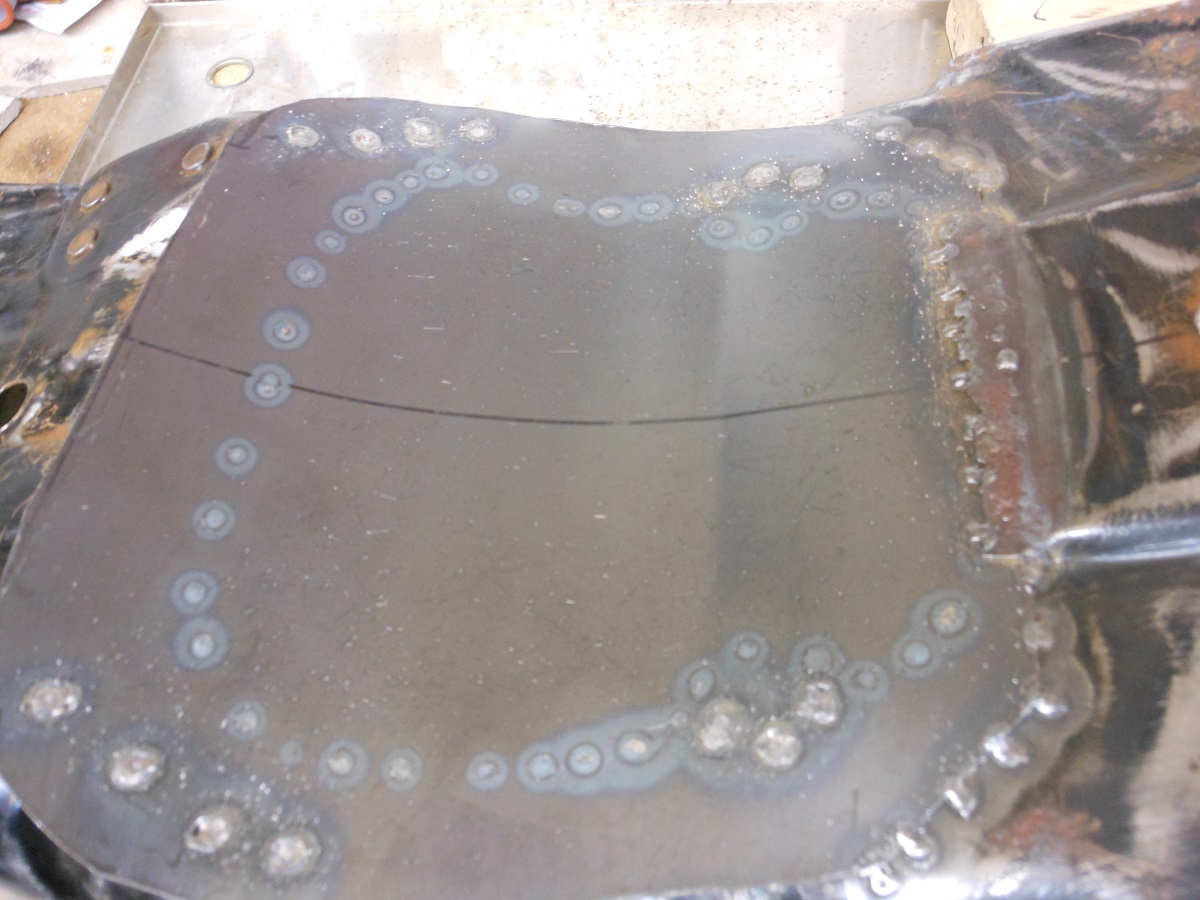

The next order of business is to mark the perimeter of this raised section - being sure to retain the holes for the rubber bottom bumpers and cut it out. I used a dremel with the reinforced cutting wheels - expect to go through 4 to 6 of them by the time you're done. It will look like this:

I used a grinding wheel in the dremel to smooth out the ragged edges a bit.

Next, make a cardboard template for a new bit of sheet to cover the hole. The top edge of the back should be level with the top surfaces of the seat mount latch towers on each side. Here's my template:

Cut this out of 16 gauge sheet, and then form to sit in the curved profile of the pan - it should sit flat on the pan without rocking or having to be forced into place. When satisfied with the fit, weld it in place.

Welded on the top - note the upper back edge alignment with the top of the latch towers.

Welded on the top - note the upper back edge alignment with the top of the latch towers.

Welded the bottom. Drill the rubber bumper holes through the new sheet metal overlay.

Welded the bottom. Drill the rubber bumper holes through the new sheet metal overlay.

Of the three seats I have done so far, only one has had the factory vinyl edge protector somewhat intact. NONE have had an intact edge protector at the lower skirt corner where it's needed most. Unable to come up with any suitable replacement, I worked the bottom edges with a file and emery paper so there were no sharp edges over which the cover will be stretched. After all this is done, clean, sand, prep and paint the pan - when the paint has cured, it will be time to move on to building up the foam.

Coming up...Part 2 Fun with Foam

Please note that this modification is for the late model (1980) and later special and special 2 models with the lift off saddle. I'm also not the greatest at documenting projects as I go along - tend to get involved in the work and forget all about the camera on the workbench - I apologize in advance for any lacking detail in the accompanying photos.

This modification will lower the seating position, and requires sheet metal cutting, forming and welding - but nothing too complicated. There is also some considerable foam work - still nothing terribly complicated. The end result will be a saddle much more comfortable than the stock configuration with support in the right places.

The first order of business is to correct the issue in the foundation of the seat pan itself. The stock pan has a glaring issue in its construction that makes for an uncomfortable seat as the foam is compressed and you're left sitting on some very uncomfortable pressure points. Here's the starting point - Seat in need of rebuild - cover torn and foam beginning to break down.

Carefully bend out the holding teeth and remove the cover - bend them only enough to get the old cover out from under - I have had most success at bending no more that 45 degrees or so...

Remove the seat cover and the old foam. Try to remove the foam in one piece, particularly the pillion portion, as it will be re-used. The bare pan now exposes the problem area that needs to be addressed.

Note the raised center part - this is what you're sitting on when the foam compresses - about 6 inches wide and slanted forward - it will make your backside sore in a short time.

The next order of business is to mark the perimeter of this raised section - being sure to retain the holes for the rubber bottom bumpers and cut it out. I used a dremel with the reinforced cutting wheels - expect to go through 4 to 6 of them by the time you're done. It will look like this:

I used a grinding wheel in the dremel to smooth out the ragged edges a bit.

Next, make a cardboard template for a new bit of sheet to cover the hole. The top edge of the back should be level with the top surfaces of the seat mount latch towers on each side. Here's my template:

Cut this out of 16 gauge sheet, and then form to sit in the curved profile of the pan - it should sit flat on the pan without rocking or having to be forced into place. When satisfied with the fit, weld it in place.

Of the three seats I have done so far, only one has had the factory vinyl edge protector somewhat intact. NONE have had an intact edge protector at the lower skirt corner where it's needed most. Unable to come up with any suitable replacement, I worked the bottom edges with a file and emery paper so there were no sharp edges over which the cover will be stretched. After all this is done, clean, sand, prep and paint the pan - when the paint has cured, it will be time to move on to building up the foam.

Coming up...Part 2 Fun with Foam