- as usual what you take from this will simply be a figment of your imagination…im an xspurt not an xspert…once upon a time I was the top of my swimming class, that was about when my advantages stopped…

What are LED’s ?

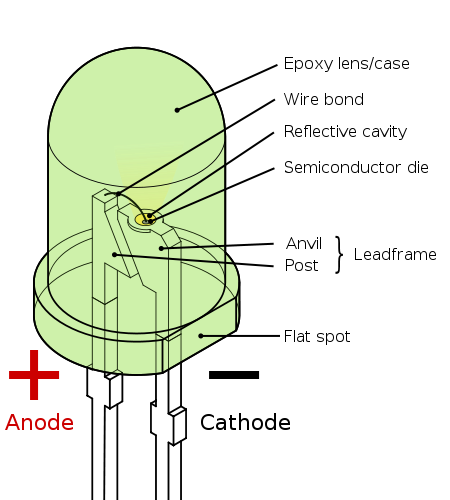

- small semi-conductor diodes-diodes conduct electric current in only one direction

- can be used as relief valves, rectifiers to convert ac to dc or modulators eg radio waves

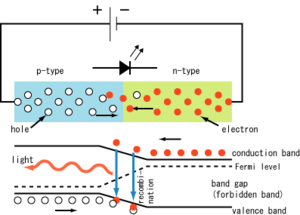

- P-N junction design exploits non-linear electrical properties for specific uses, zener diodes for voltage regulation, varactor diodes for radio and tv tuning, tunnel diodes generate rf waves and LEDs emit light…recombination of N-type e- with P-type holes causes emission of photons or light

P-positive side, holes or empty electron sites

N-negative side, free electrons

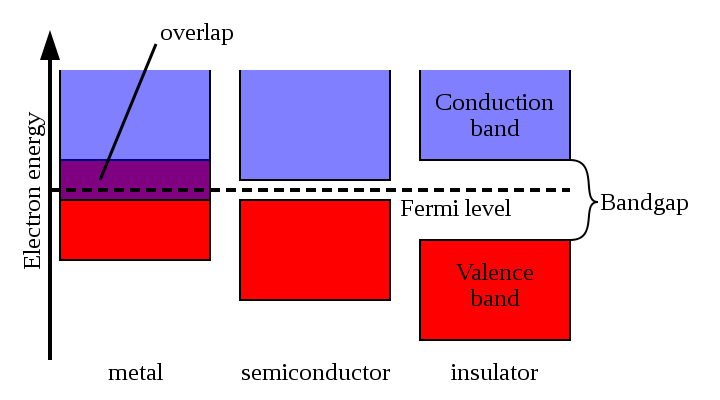

- -zero and overlapping bandgaps are conductors

- -small bandgaps are semi-conductors…less than 3-4eV

- -large bandgaps are insulators

- Critical factors…band gap, electron mobility-conductance

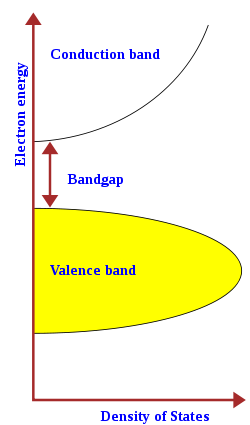

Band gap…energy required to free an electron so it can pass between the outer valence shell and conductance bands-discrete electron activity probability zones

- depends on the material..LED’s are usually AluminiumGalliumArsenide, AlGaNitride

- depends on pressure-

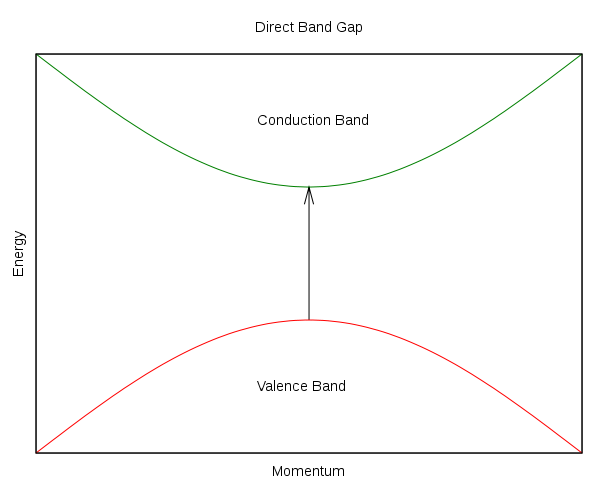

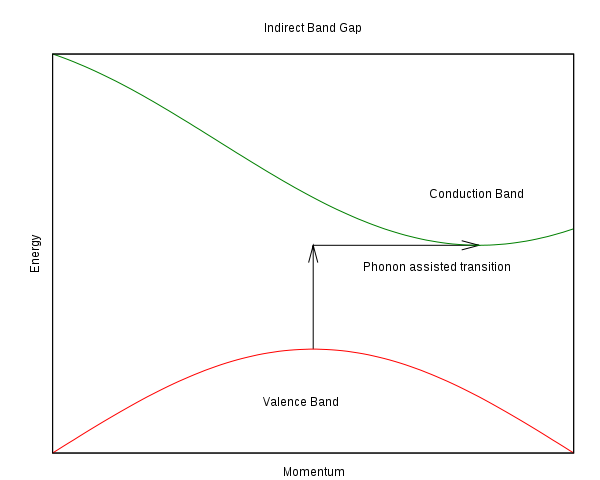

direct ... valence band max energy equals conductance band min energy

indirect … these are not equal eg. silicone…emit heat, not used for LED’s

- depends on crystalline stucture

- decreases with increasing temperature

- controlled via semi-conductor alloy composition, doping GaAs GaN or layering

- absorbs or emits heat, phonon and or light, photon

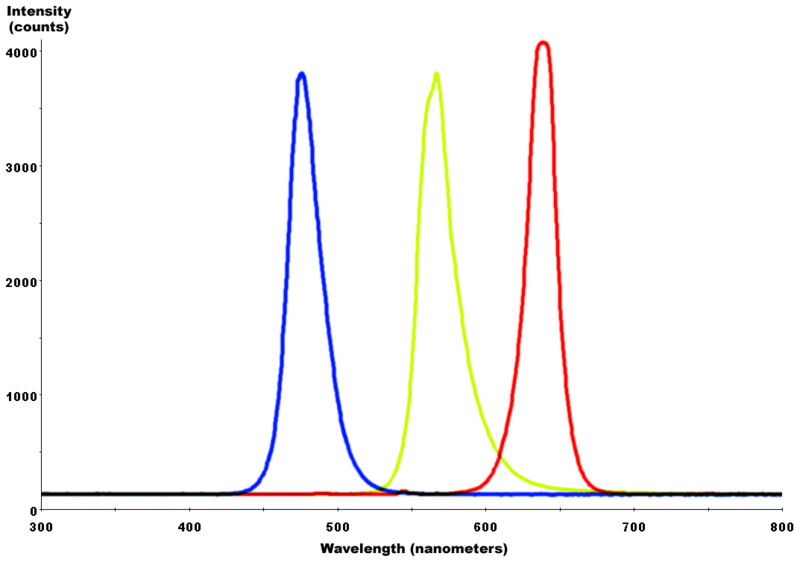

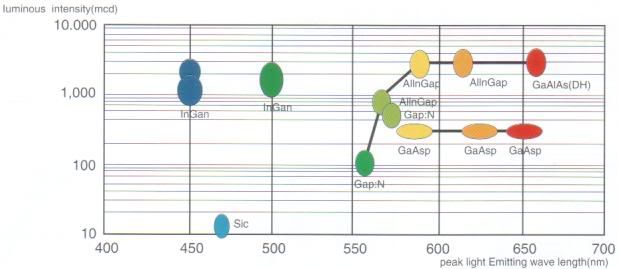

In direct band-gap semiconductor diodes, eg. gallium arsenide, junction crossing n e- emit photons when recombining on the p side, producing, dependant on material, wavelengths (or colours) from infrared to near ultraviolet. Diode forward potential corresponds to the emitted photons desired wavelength: 1.2 V corresponds to red, 2.4 V to violet. Originally LEDs were red and yellow, higher-frequency diodes being later developed. All LEDs produce incoherent, narrow-spectrum light; “white” LEDs are actually combinations of three LEDs of a different color, or a blue LED with a yellow scintillator-phosphorous coating.

LED’s gained use for low power indicator applications eg. a green and red 5mm LED’s as switching reminders. Future LED technology will include… OLED’s, nanotech...

Currently, benefits are most seen in low voltage ( 12 to 24 volt DC) automotive, marine and alternative power applications. Advances will attain higher levels of illumination, with high power LED lights replacing fluorescent, incandescent, and halogen light bulbs.

The key is understanding LED power and cost efficiencies.

Power efficiency allows comparison of various lighting systems, "lumens per watt" indicates total luminous output, compared to overall power dissipation.

Cost efficiency, "lumens per dollar", indicates luminous output, compared to actual manufacturing costs.

Although LED circuits can provide energy efficiencies equal to or better than most traditional light sources, high production costs offset energy efficiency. Savings only occur long-term.

.

Unlike incandescent light bulbs LED’s require thermal management. Heat produced during LED operation transfers downward into the circuit board. Design must dissipate this away from the LED.

LED drivers

LED bulbs are often driven using series resistance, this works okay so long as no external loads are applied eg. compressor, pump, headlight…immediately decreases both current and voltage, seriously affecting LED lifetime.

Due to low start-up demand, LED bulbs are extremely sensitive to current and voltage spikes. Low battery voltages increase resistance causing heat, high voltages risk premature failure or dimming by overdriving the LED.

Constant current LED’s incorporate small integrated circuits sensing any voltage variations, automatically compensating for losses.

Miniscule chemical substrate variations can cause fluctuations in current demand.

Temperature is also a problem. As temperature increases with current, improper current regulation can cause voltage to rise leading to early failure.

What does this mean for XS650’s

That’s going to depend on what you have done to your bike…oem alternators and charging systems will love you. LED’s decrease power demand considerably, taking a load off the battery and charging system. Those, like me, who run a PM system have the opposite problem-what to do with all the xs power.

Most will think about installing LED indicators, some will consider replacing the tail, brake and number plate lights. Some will replace the headlight. My SR has LED dial lights and highbeam, neutral and blinker warning lamps.

If youre into design, build your own custom lights to fit any available space. Internally wired and set individually into the frame. I could envision future uses of OLED-Organic LED-surface coating applications for some pretty futuristic colour and lighting effects

LEDs require direct current DC with low voltage, not the AC supplied by our alternators.

Functioning rec-regs are required, the rectifier to to convert AC to DC , the regulator to maintain a constant voltage as are a battery or capacitor for power supply smoothing.

Voltage control is important. As current is approximately an exponential function of voltage, small voltage changes result in large changes in current

Voltage below the threshold, on-voltage, produces no current, no current – no light. High voltage pushes current above the maximum rating, overdriving and heating LEDs. As they heat, voltage drop decreases with band gap, further increasing current.

Series or Parallel

Connect LEDs directly to constant-voltage sources with either, Series resistors, simple but wastes energy as heat, or, a constant current regulator commonly used for high power LEDs. Low drop-out (LDO) constant current regulators improve efficiency and reduce power use

Miniature indicator LEDs are normally driven from low voltage DC via a current limiting resistor. Currents of 2 mA, 10 mA and 20 mA are common. Sub-mA indicators may be made by driving ultrabright LEDs at very low current. Although efficiency is reduced at low currents, running 100μA indicators is still practical.

Operate LED strings in series. Total LED voltage should be around two-thirds the supply voltage, each string being resistor current controlled.

A single series string minimizes dropper losses, while paralleled strings increase reliability. In practice usually three strings or more are used. Using a capacitor can reduce high line voltage without wasting power, with a very simple circuit; there may be a short high current surge upon start-up.

Parallel operation is also possible but can be more problematic. Branch currents must be equal, Parallel LEDs must have closely matched forward voltages (Vf) for equal light output. Variations in the manufacturing process add to the challenge.

Some LEDs have built in series resistors, saves PCB space, and are useful when building prototypes or custom PCBs. Resistor value is set when manufactured, blocking a key method for setting LED intensity. Seven-segment and starburst LED arrays are available in both common-anode and common-cathode form.

resistor calculator

The formula to calculate the correct resistance to use is:

{power supply voltage} (V_s) - {LED voltage drop} (V_f) = {resistance in ohms} (R)

------------------------------------------------------

{LED current rating}(I_f)

where:

* Power supply voltage (Vs) is the voltage of the power supply e.g. a 9 volt battery.

* LED voltage drop (Vf) is the voltage drop across the LED (typically about 1.8 - 3.3 volts; this varies by the color of the LED) 1.8 volts for red and its gets higher as the spectrum increases to 3.3 volts for blue.

* LED current rating (If) is the manufacturer rating of the LED (usually given in milliamperes such as 20 mA)

http://www.hebeiltd.com.cn/?p=zz.led.resistor.calculator

http://www.webbikeworld.com/lights/

http://www.customdynamics.com/pdf/Cust_Dyn_Catalog.pdf

http://www.radiantz.com/cart/index1.html?c34.html&1

home build…

http://www.maushammer.com/systems/tail-light/index.html

headlight…

http://ecomodder.com/forum/showthread.php/led-headlight-6514.html

http://www.instructables.com/id/LED_Motorcycle_Headlight/

LED light…

http://www.ehow.com/how_4727328_build-led-motorcycle-light.html

taillight…

http://blog.makezine.com/archive/2008/02/led_motorcycle_tail_light.html

What are LED’s ?

- small semi-conductor diodes-diodes conduct electric current in only one direction

- can be used as relief valves, rectifiers to convert ac to dc or modulators eg radio waves

- P-N junction design exploits non-linear electrical properties for specific uses, zener diodes for voltage regulation, varactor diodes for radio and tv tuning, tunnel diodes generate rf waves and LEDs emit light…recombination of N-type e- with P-type holes causes emission of photons or light

P-positive side, holes or empty electron sites

N-negative side, free electrons

- -zero and overlapping bandgaps are conductors

- -small bandgaps are semi-conductors…less than 3-4eV

- -large bandgaps are insulators

- Critical factors…band gap, electron mobility-conductance

Band gap…energy required to free an electron so it can pass between the outer valence shell and conductance bands-discrete electron activity probability zones

- depends on the material..LED’s are usually AluminiumGalliumArsenide, AlGaNitride

- depends on pressure-

direct ... valence band max energy equals conductance band min energy

indirect … these are not equal eg. silicone…emit heat, not used for LED’s

- depends on crystalline stucture

- decreases with increasing temperature

- controlled via semi-conductor alloy composition, doping GaAs GaN or layering

- absorbs or emits heat, phonon and or light, photon

In direct band-gap semiconductor diodes, eg. gallium arsenide, junction crossing n e- emit photons when recombining on the p side, producing, dependant on material, wavelengths (or colours) from infrared to near ultraviolet. Diode forward potential corresponds to the emitted photons desired wavelength: 1.2 V corresponds to red, 2.4 V to violet. Originally LEDs were red and yellow, higher-frequency diodes being later developed. All LEDs produce incoherent, narrow-spectrum light; “white” LEDs are actually combinations of three LEDs of a different color, or a blue LED with a yellow scintillator-phosphorous coating.

LED’s gained use for low power indicator applications eg. a green and red 5mm LED’s as switching reminders. Future LED technology will include… OLED’s, nanotech...

Currently, benefits are most seen in low voltage ( 12 to 24 volt DC) automotive, marine and alternative power applications. Advances will attain higher levels of illumination, with high power LED lights replacing fluorescent, incandescent, and halogen light bulbs.

The key is understanding LED power and cost efficiencies.

Power efficiency allows comparison of various lighting systems, "lumens per watt" indicates total luminous output, compared to overall power dissipation.

Cost efficiency, "lumens per dollar", indicates luminous output, compared to actual manufacturing costs.

Although LED circuits can provide energy efficiencies equal to or better than most traditional light sources, high production costs offset energy efficiency. Savings only occur long-term.

.

Unlike incandescent light bulbs LED’s require thermal management. Heat produced during LED operation transfers downward into the circuit board. Design must dissipate this away from the LED.

LED drivers

LED bulbs are often driven using series resistance, this works okay so long as no external loads are applied eg. compressor, pump, headlight…immediately decreases both current and voltage, seriously affecting LED lifetime.

Due to low start-up demand, LED bulbs are extremely sensitive to current and voltage spikes. Low battery voltages increase resistance causing heat, high voltages risk premature failure or dimming by overdriving the LED.

Constant current LED’s incorporate small integrated circuits sensing any voltage variations, automatically compensating for losses.

Miniscule chemical substrate variations can cause fluctuations in current demand.

Temperature is also a problem. As temperature increases with current, improper current regulation can cause voltage to rise leading to early failure.

What does this mean for XS650’s

That’s going to depend on what you have done to your bike…oem alternators and charging systems will love you. LED’s decrease power demand considerably, taking a load off the battery and charging system. Those, like me, who run a PM system have the opposite problem-what to do with all the xs power.

Most will think about installing LED indicators, some will consider replacing the tail, brake and number plate lights. Some will replace the headlight. My SR has LED dial lights and highbeam, neutral and blinker warning lamps.

If youre into design, build your own custom lights to fit any available space. Internally wired and set individually into the frame. I could envision future uses of OLED-Organic LED-surface coating applications for some pretty futuristic colour and lighting effects

LEDs require direct current DC with low voltage, not the AC supplied by our alternators.

Functioning rec-regs are required, the rectifier to to convert AC to DC , the regulator to maintain a constant voltage as are a battery or capacitor for power supply smoothing.

Voltage control is important. As current is approximately an exponential function of voltage, small voltage changes result in large changes in current

Voltage below the threshold, on-voltage, produces no current, no current – no light. High voltage pushes current above the maximum rating, overdriving and heating LEDs. As they heat, voltage drop decreases with band gap, further increasing current.

Series or Parallel

Connect LEDs directly to constant-voltage sources with either, Series resistors, simple but wastes energy as heat, or, a constant current regulator commonly used for high power LEDs. Low drop-out (LDO) constant current regulators improve efficiency and reduce power use

Miniature indicator LEDs are normally driven from low voltage DC via a current limiting resistor. Currents of 2 mA, 10 mA and 20 mA are common. Sub-mA indicators may be made by driving ultrabright LEDs at very low current. Although efficiency is reduced at low currents, running 100μA indicators is still practical.

Operate LED strings in series. Total LED voltage should be around two-thirds the supply voltage, each string being resistor current controlled.

A single series string minimizes dropper losses, while paralleled strings increase reliability. In practice usually three strings or more are used. Using a capacitor can reduce high line voltage without wasting power, with a very simple circuit; there may be a short high current surge upon start-up.

Parallel operation is also possible but can be more problematic. Branch currents must be equal, Parallel LEDs must have closely matched forward voltages (Vf) for equal light output. Variations in the manufacturing process add to the challenge.

Some LEDs have built in series resistors, saves PCB space, and are useful when building prototypes or custom PCBs. Resistor value is set when manufactured, blocking a key method for setting LED intensity. Seven-segment and starburst LED arrays are available in both common-anode and common-cathode form.

resistor calculator

The formula to calculate the correct resistance to use is:

{power supply voltage} (V_s) - {LED voltage drop} (V_f) = {resistance in ohms} (R)

------------------------------------------------------

{LED current rating}(I_f)

where:

* Power supply voltage (Vs) is the voltage of the power supply e.g. a 9 volt battery.

* LED voltage drop (Vf) is the voltage drop across the LED (typically about 1.8 - 3.3 volts; this varies by the color of the LED) 1.8 volts for red and its gets higher as the spectrum increases to 3.3 volts for blue.

* LED current rating (If) is the manufacturer rating of the LED (usually given in milliamperes such as 20 mA)

http://www.hebeiltd.com.cn/?p=zz.led.resistor.calculator

http://www.webbikeworld.com/lights/

http://www.customdynamics.com/pdf/Cust_Dyn_Catalog.pdf

http://www.radiantz.com/cart/index1.html?c34.html&1

home build…

http://www.maushammer.com/systems/tail-light/index.html

headlight…

http://ecomodder.com/forum/showthread.php/led-headlight-6514.html

http://www.instructables.com/id/LED_Motorcycle_Headlight/

LED light…

http://www.ehow.com/how_4727328_build-led-motorcycle-light.html

taillight…

http://blog.makezine.com/archive/2008/02/led_motorcycle_tail_light.html