This is going to be a rather long thread in which I'll share all the knowledge I've gathered on the locks and keys these bikes use. These are sadly neglected parts and most haven't been touched or serviced since they left the factory so are (way) past due. Renovating (cleaning, lubing) your lock assemblies is the perfect cold weather or winter project.

So, let's start with the keys and key blanks. I'll be covering mainly the keys from 1976 on because that's what I've mostly dealt with and have access to. The '76-'80 keys and locks have a 4 number code. You'll find it stamped on the lock face and on the key (if it's original) .....

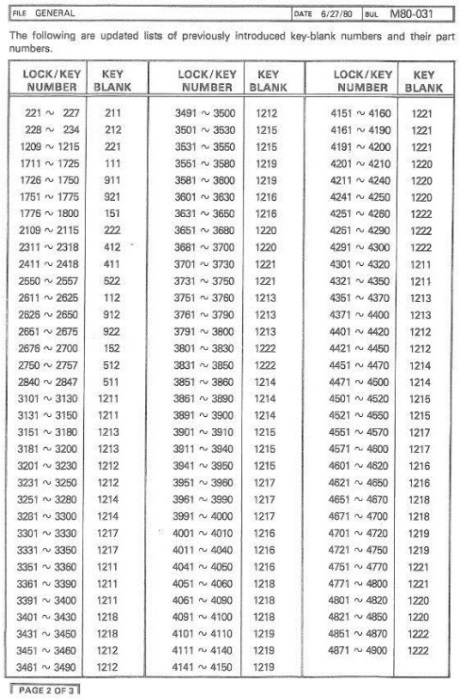

To figure out what key blank you need, Yamaha was kind enough to publish a tech bulletin with a list. The '76-'80 locks/keys will have code numbers starting at 3101 and running up to 4900. The key blanks will be 1211-1222. The locks/keys below 3101 and the blanks with 3 number codes are for the '75 and older locks. Like I said, I don't know as much about them but I can tell you the keys are physically smaller and narrower, some are even only one-sided, and the Ilco YH46-YH51 blanks listed below will not fit them. Ilco probably does make blanks to fit them, I just never researched them because I didn't need any .....

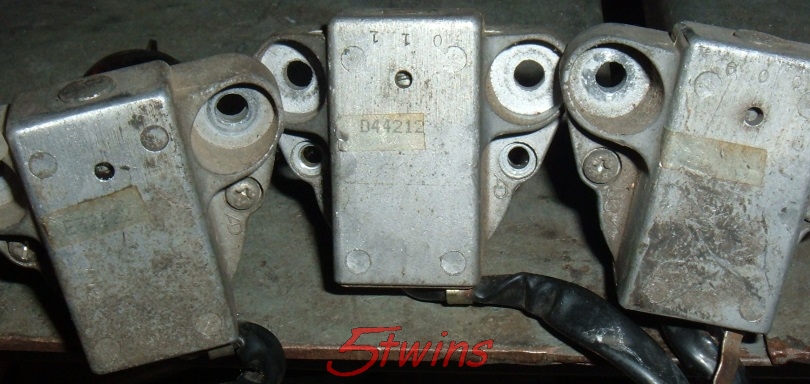

In 1981, the key codes and blanks were changed. They switched to a letter (and 5 numbers). They also no longer stamped the code on the face of the lock, instead placing a sticker on the bottom of the ignition switch/fork lock assembly. Unfortunately, on many the writing on the stickers has worn away after all these years, or the sticker is gone completely. Eventually, after a few years, Yamaha started stamping the code right into the metal base. My '83 is like this, having the code actually stamped into the metal .....

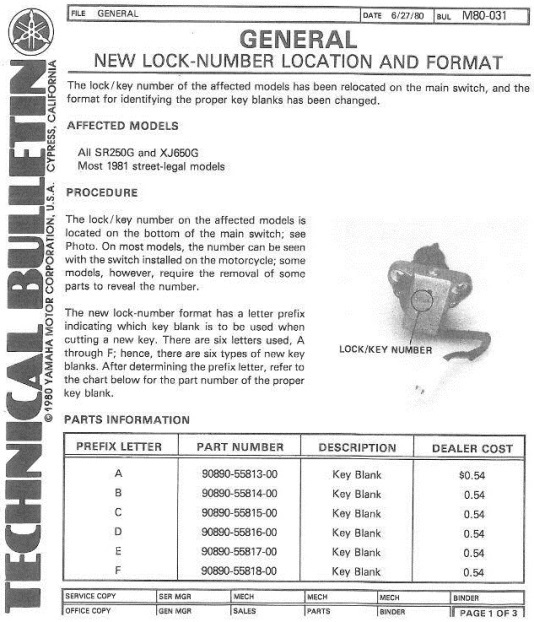

..... and another Tech Bulletin was issued .....

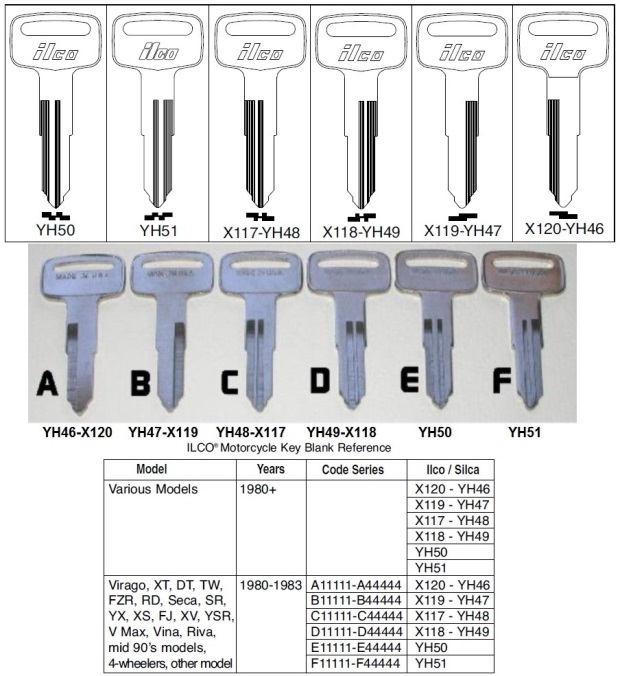

But Yamaha key blanks have gotten outrageously expensive, retailing for as much as $20, so it would be nice to be able to find and use aftermarket blanks. Ilco makes pretty much all we need and here's some info .....

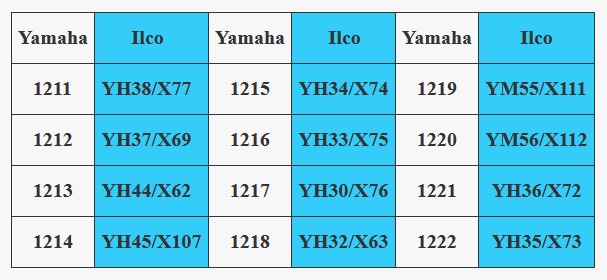

If you study the above pic, you'll see that even though there are 6 different blanks, they are actually 3 mirror imaged pairs. Which blanks match the new letter codes is also shown. But, what about the earlier 4 number code keys and locks? How do the blanks match up to those? Well, through much research, I've pretty much worked that out. Based on the locks, original keys, and aftermarket blanks I have, along with pics of all the factory blanks from eBay, I was able to figure it out and I've put together a cross reference chart .....

The later letter code blanks are simply longer versions of some of the earlier blanks, probably adopted to make using the "push-down" feature to activate access to the fork lock easier. Here's a 1211 and it's longer counterpart, the 1225 .....

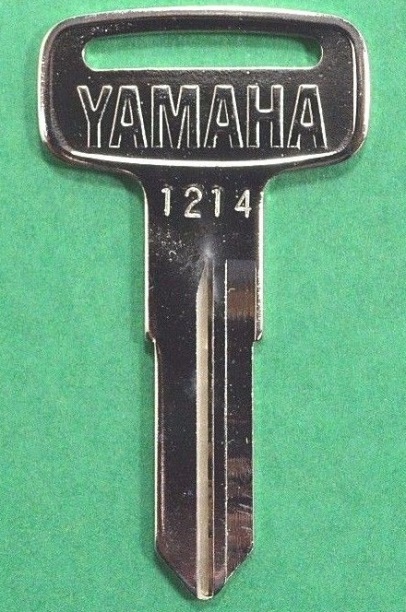

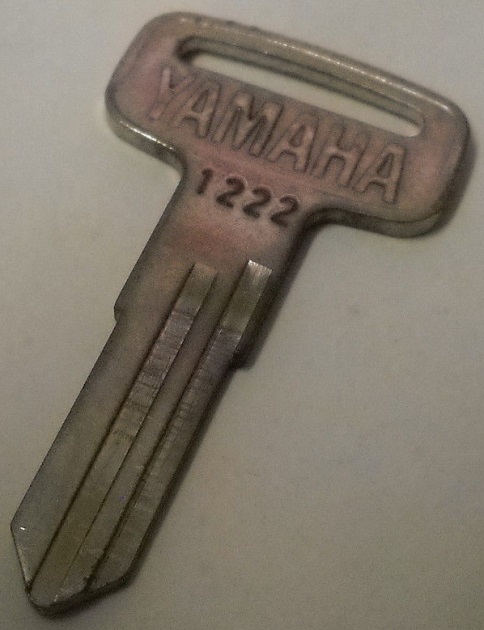

You'll also notice there are more Yamaha blanks than aftermarket Ilcos (12 Yamaha blanks, or 6 mirror imaged pairs) listed for the 4 number code keys/locks. There are differences in them, notably in the groove widths that run down them. The Ilco blanks are more "generic", crossing over and fitting several Yamaha locks. As an example, here's a 1214 and 1222 Yamaha blank. You can plainly see the groove down the center is wider on the 1222 .....

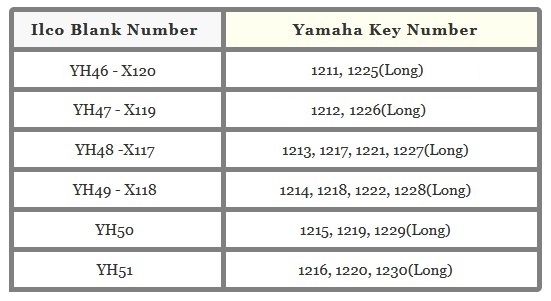

A 1214 Yamaha blank won't fit into a 1222 lock nor will a 1222 blank fit a 1214 lock, but the Ilco YH49 blank will fit and work for both. Now while technically, the YH46-YH51 blanks shown above are for the '80s letter code locks, I've always been able to find one that fits any earlier 4 number code lock I've encountered. But, upon further research, it seems Ilco does make specific blanks for these 4 number code locks. They may be harder to find, and are priced a bit higher than the letter code blanks, but these give you even more options. Here they are .....

The benefit of using aftermarket blanks is they're much cheaper, only a few dollars each. But, if you insist on genuine Yamaha blanks, here's some part numbers for you .....

So, if you have what you thought was an original Yamaha key that came with your bike and the number stamped on it starts with a "12", it's a Yamaha blank that was cut to fit, not the original key issued with the bike.

So, let's start with the keys and key blanks. I'll be covering mainly the keys from 1976 on because that's what I've mostly dealt with and have access to. The '76-'80 keys and locks have a 4 number code. You'll find it stamped on the lock face and on the key (if it's original) .....

To figure out what key blank you need, Yamaha was kind enough to publish a tech bulletin with a list. The '76-'80 locks/keys will have code numbers starting at 3101 and running up to 4900. The key blanks will be 1211-1222. The locks/keys below 3101 and the blanks with 3 number codes are for the '75 and older locks. Like I said, I don't know as much about them but I can tell you the keys are physically smaller and narrower, some are even only one-sided, and the Ilco YH46-YH51 blanks listed below will not fit them. Ilco probably does make blanks to fit them, I just never researched them because I didn't need any .....

In 1981, the key codes and blanks were changed. They switched to a letter (and 5 numbers). They also no longer stamped the code on the face of the lock, instead placing a sticker on the bottom of the ignition switch/fork lock assembly. Unfortunately, on many the writing on the stickers has worn away after all these years, or the sticker is gone completely. Eventually, after a few years, Yamaha started stamping the code right into the metal base. My '83 is like this, having the code actually stamped into the metal .....

..... and another Tech Bulletin was issued .....

But Yamaha key blanks have gotten outrageously expensive, retailing for as much as $20, so it would be nice to be able to find and use aftermarket blanks. Ilco makes pretty much all we need and here's some info .....

If you study the above pic, you'll see that even though there are 6 different blanks, they are actually 3 mirror imaged pairs. Which blanks match the new letter codes is also shown. But, what about the earlier 4 number code keys and locks? How do the blanks match up to those? Well, through much research, I've pretty much worked that out. Based on the locks, original keys, and aftermarket blanks I have, along with pics of all the factory blanks from eBay, I was able to figure it out and I've put together a cross reference chart .....

The later letter code blanks are simply longer versions of some of the earlier blanks, probably adopted to make using the "push-down" feature to activate access to the fork lock easier. Here's a 1211 and it's longer counterpart, the 1225 .....

You'll also notice there are more Yamaha blanks than aftermarket Ilcos (12 Yamaha blanks, or 6 mirror imaged pairs) listed for the 4 number code keys/locks. There are differences in them, notably in the groove widths that run down them. The Ilco blanks are more "generic", crossing over and fitting several Yamaha locks. As an example, here's a 1214 and 1222 Yamaha blank. You can plainly see the groove down the center is wider on the 1222 .....

A 1214 Yamaha blank won't fit into a 1222 lock nor will a 1222 blank fit a 1214 lock, but the Ilco YH49 blank will fit and work for both. Now while technically, the YH46-YH51 blanks shown above are for the '80s letter code locks, I've always been able to find one that fits any earlier 4 number code lock I've encountered. But, upon further research, it seems Ilco does make specific blanks for these 4 number code locks. They may be harder to find, and are priced a bit higher than the letter code blanks, but these give you even more options. Here they are .....

The benefit of using aftermarket blanks is they're much cheaper, only a few dollars each. But, if you insist on genuine Yamaha blanks, here's some part numbers for you .....

So, if you have what you thought was an original Yamaha key that came with your bike and the number stamped on it starts with a "12", it's a Yamaha blank that was cut to fit, not the original key issued with the bike.

Last edited: