How do you guys cut out the larger holes in gasket material and what do you lay it on when you use a hole punch

I was just out in the garage making a few gaskets but when I'm using the HF hole punch set they really don't cut so much as make a deep mark in it

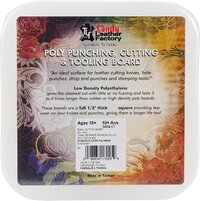

I was using OSB underneath it and maybe theres a better material to use underneath it rather than OSB

Maybe a guys got to hit it like 50 times ?

I've a utility knife / Exacto knife / and a really nice paper punch but cutting holes with an Exacto knife is a pain

I was just out in the garage making a few gaskets but when I'm using the HF hole punch set they really don't cut so much as make a deep mark in it

I was using OSB underneath it and maybe theres a better material to use underneath it rather than OSB

Maybe a guys got to hit it like 50 times ?

I've a utility knife / Exacto knife / and a really nice paper punch but cutting holes with an Exacto knife is a pain